Experiment table embedded waste liquid customized cabinet

A kind of laboratory bench, built-in technology, applied in the direction of laboratory stool/lab bench, laboratory equipment, storage of dangerous substances, etc., can solve problems such as instrument failure, achieve low cost of improvement, increase subjective evaluation of personnel, and ventilate The effect of reducing volume demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

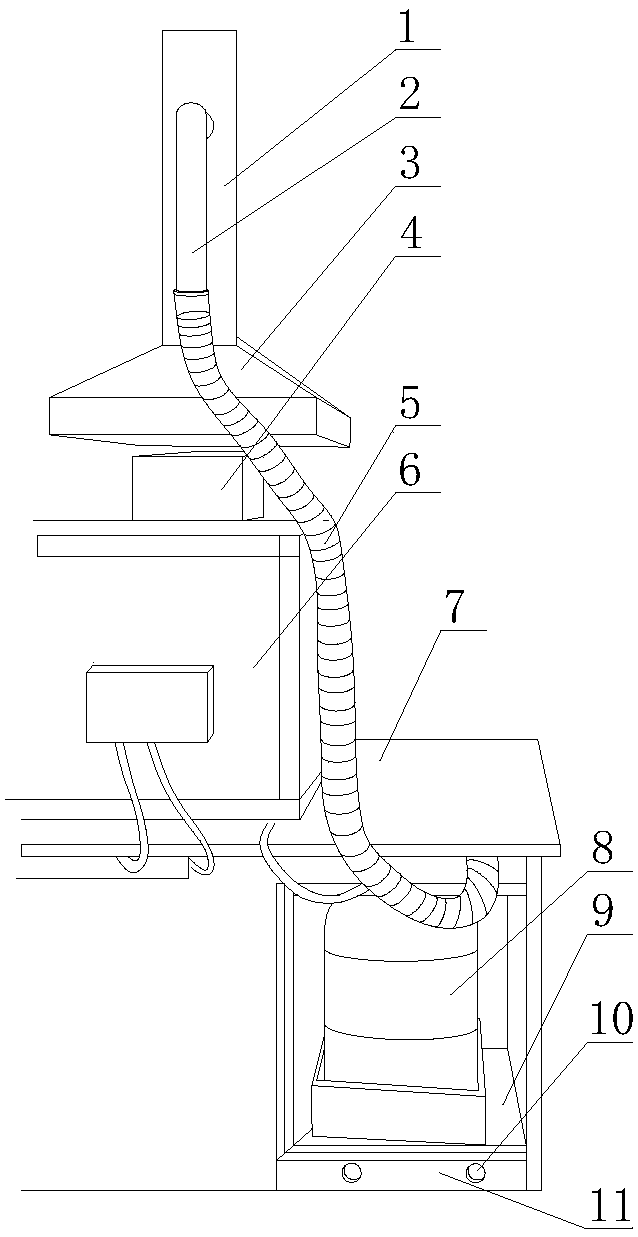

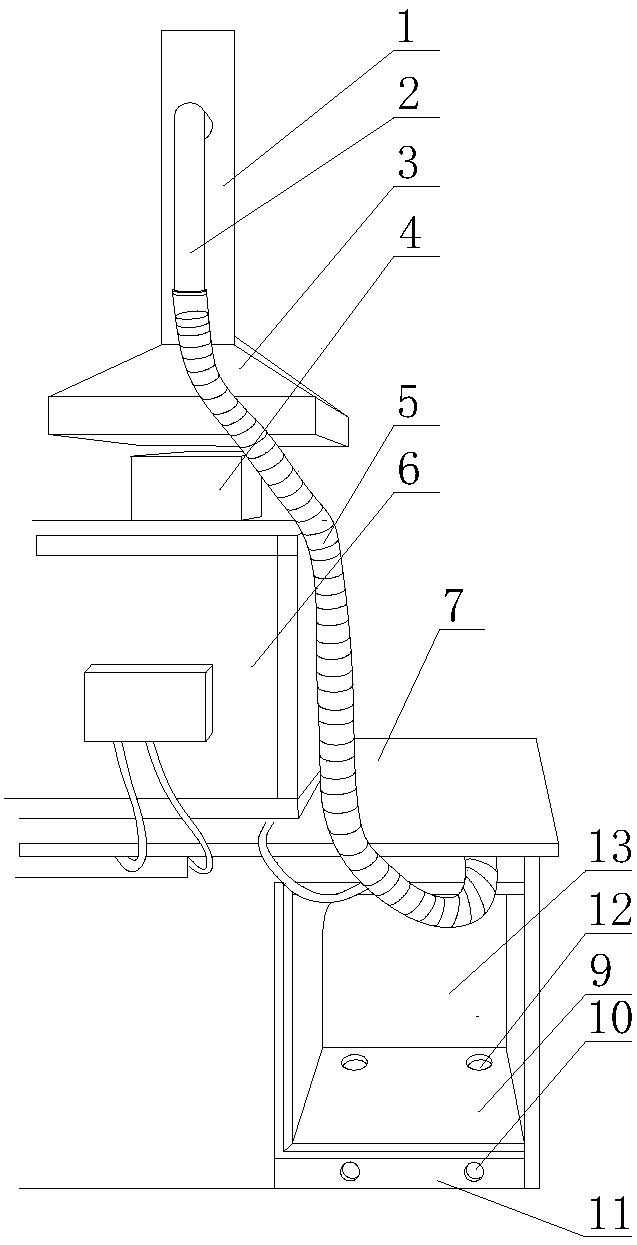

[0031] Such as figure 1 and figure 2 As shown, the built-in waste liquid custom cabinet of the test bench includes the exhaust fan, the test bench, the waste liquid cabinet and the waste liquid barrel in sequence from top to bottom. The exhaust fan includes the main exhaust pipe and the exhaust branch pipe. Cover, the suction hood is set facing the exhaust port of the testing instrument on the test bench, the end of the exhaust branch pipe is connected to one end of the exhaust pipe, and the other end of the exhaust pipe is connected to the exhaust port of the waste liquid cabinet; the waste liquid cabinet is set to The cabinet body and the cabinet door are connected to form a hollow sealed structure. There is a storage cavity under the waste liquid cabinet, and the waste liquid bucket is placed in the storage cavity. The bottom wall of the storage cavity is provided with a load-bearing plate. The bottom walls of the cabinets are spaced apart to form a hollow air duct, the i...

Embodiment 2

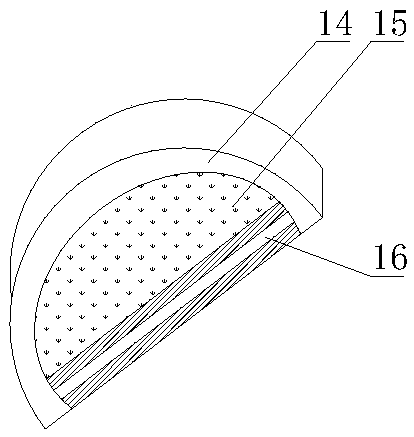

[0041] On the basis of Example 1, different from Example 1, such as image 3 As shown, the inner wall of the suction hood is provided with a detachable adsorption gasket, and the port of the adsorption gasket is provided with a ventilation hole along the width direction, and an adsorption cavity is formed between the adsorption gasket and the ventilation hole, and the adsorption cotton is embedded Set in the adsorption cavity.

[0042] The adsorption gasket is set as a hollow arch bridge arc structure with openings on both sides, and the adsorption cotton is set as a structure whose inner diameter matches the adsorption cavity, and a honeycomb adsorption mesh is opened inside to improve the adsorption effect; Embedded on the inner wall of the suction hood, it is convenient and quick to disassemble and install.

[0043] The specific use process is:

[0044] The airflow discharged from the air outlet on the top of the test bench is directly absorbed into the suction hood. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com