An experimental method for simulating multi-field coupling of fluid-solid thermalization of coal mass under thermal-mechanical coupling

A technology of thermal coupling and experimental method, applied in the field of gas control and fire prevention and control in coal mine production, can solve the problem of lack of experimental analysis method and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

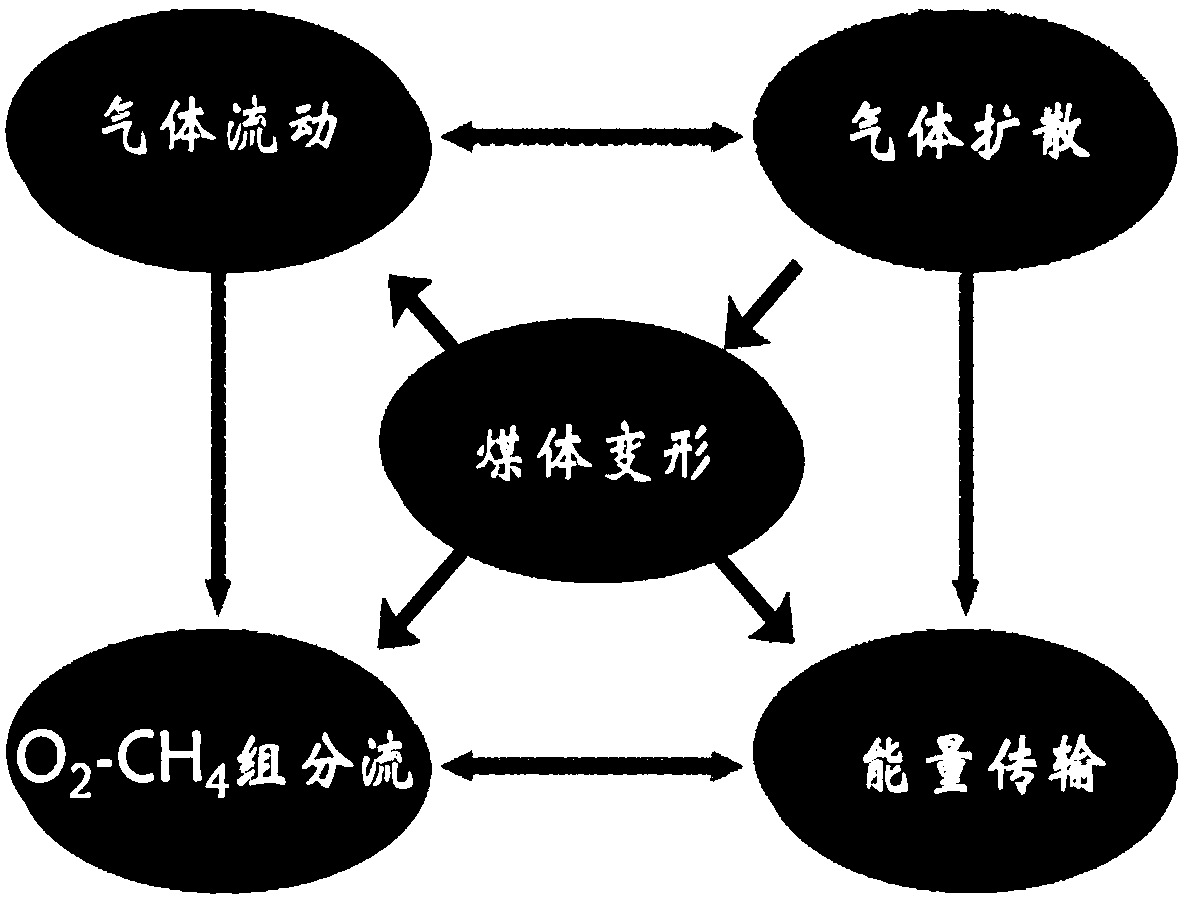

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

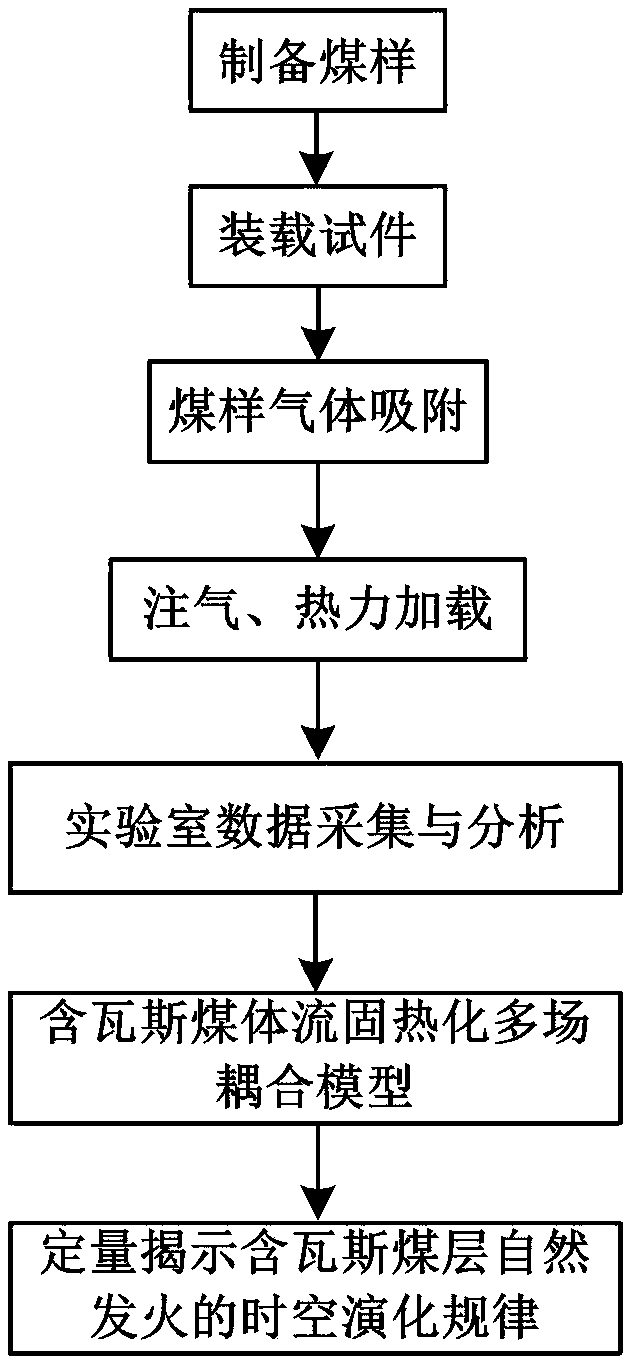

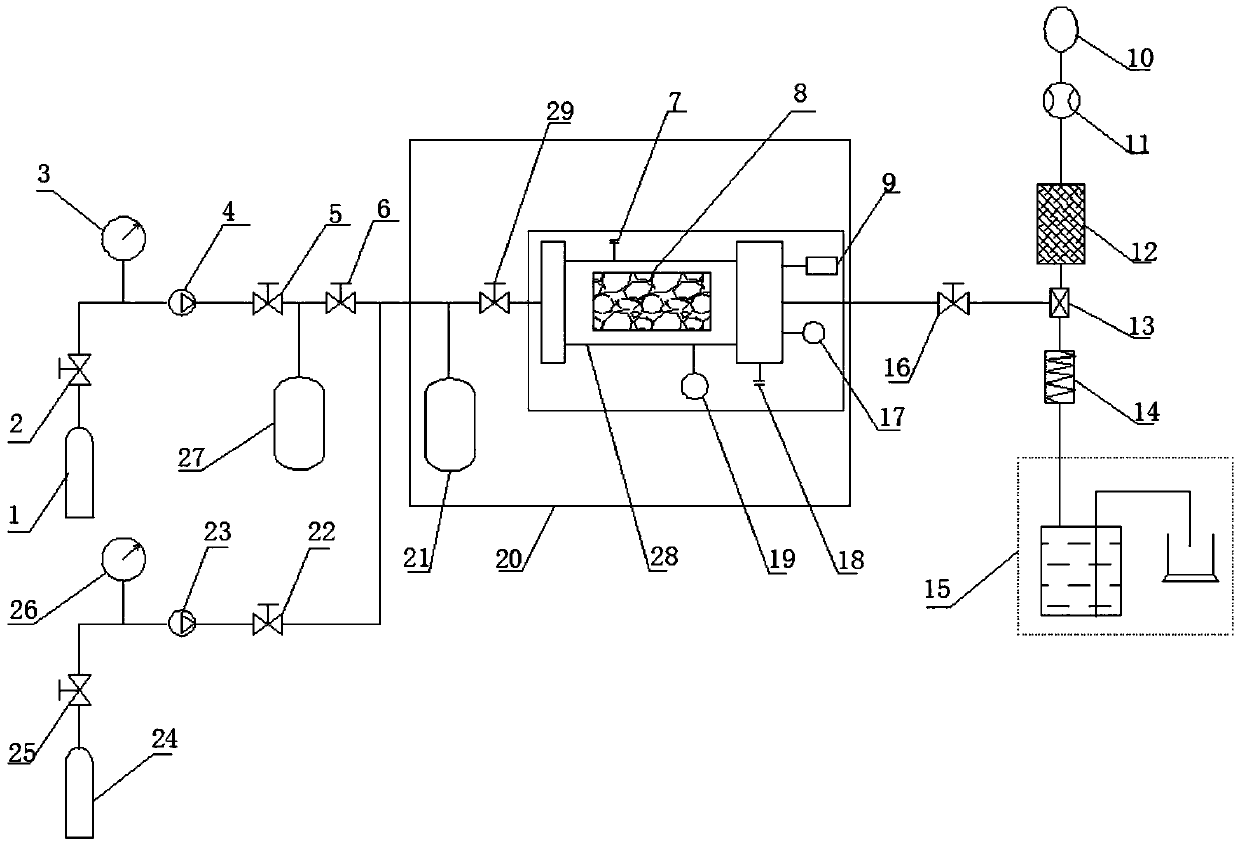

[0040] by figure 2 Take the experimental system in , as an example, an experimental method for simulating the whole coupling process of underground gas-containing coal prone to spontaneous combustion, such as figure 1 shown, including the following steps:

[0041]The first step, coal sample preparation, use a crusher to crush the lump coal into coal powder particles, and sieve coal powder particles with a particle size of 0.18mm to 0.38mm through a vibrating screen; weigh about 300g of the sieved coal powder particles, add A small amount of pure water, stir evenly and pour into the briquette mold; place the mold on a rigid hydraulic press, apply an axial load of 200KN and keep the pressure for 30 minutes, take out the successfully pressed briquette coal sample, and dry Then put it into the drying oven for later use; the prepared sample is uniformly ground into a cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com