Wire stripping device

A wire stripping and equipment technology, which is applied in the direction of dismantling/armoring cable equipment, electrical components, cable installation, etc., can solve the problems of low work efficiency, error, time-consuming, etc., and achieve high work efficiency, high precision, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

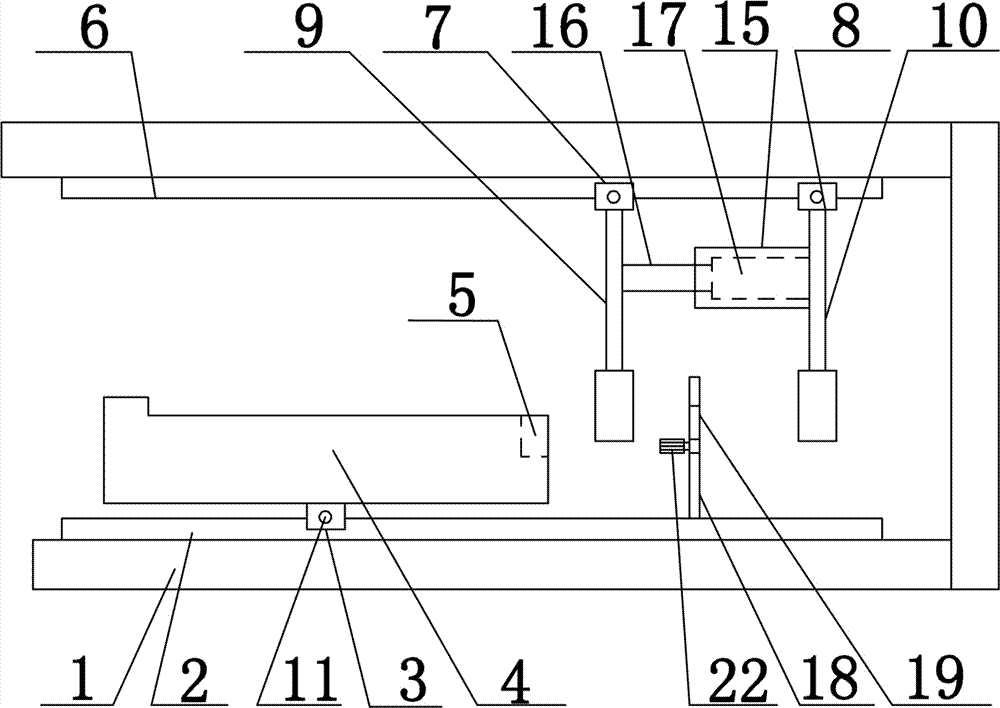

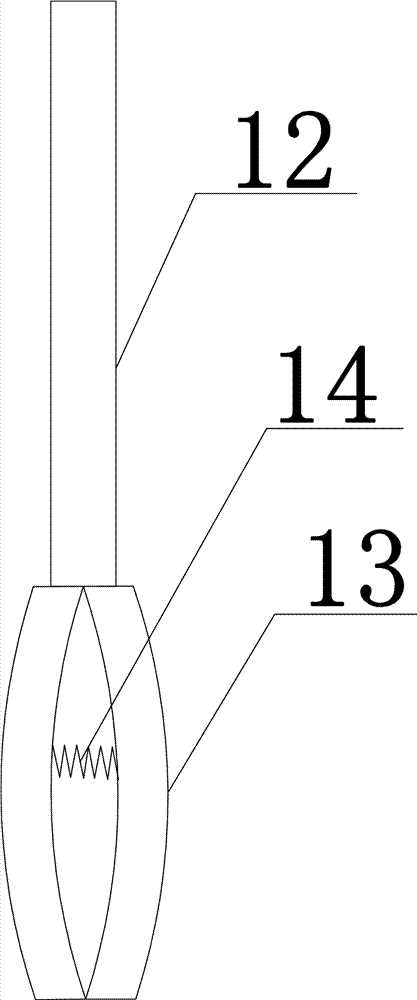

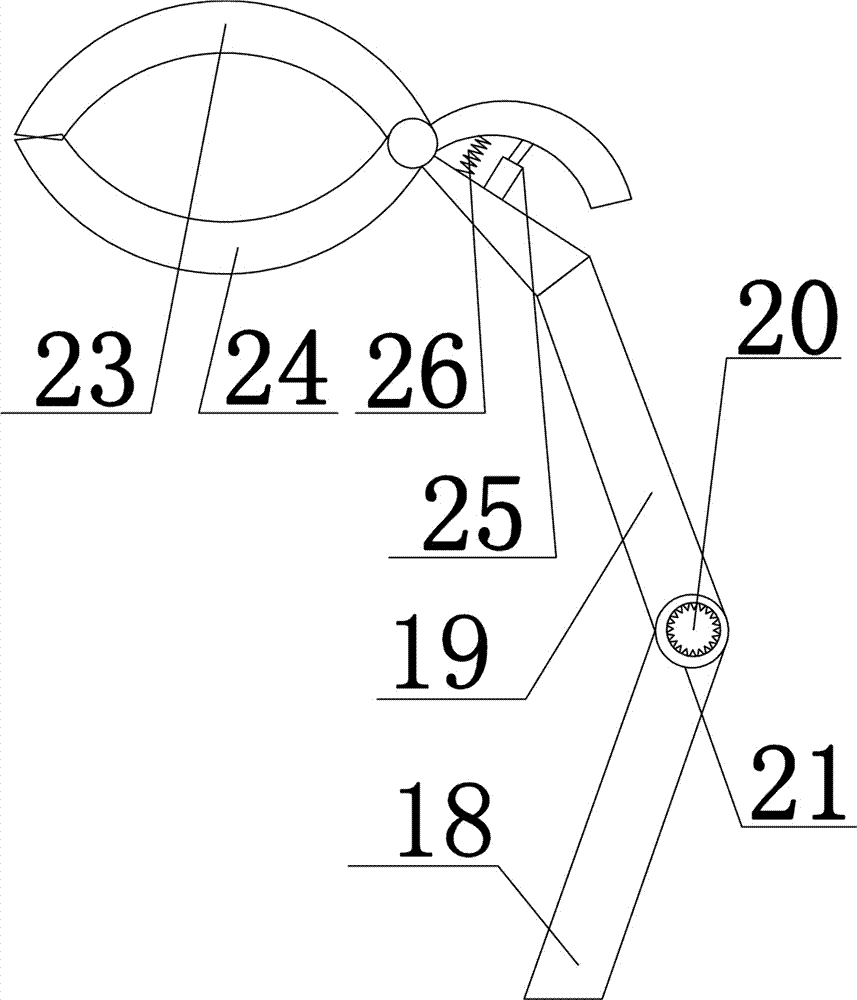

[0020] As shown in the figure, the present invention relates to a wire stripping equipment, including a workbench 1, on which a first guide rail 2 is arranged, and a first slide block 3 is provided on the first guide rail 2, and the The top of the first slider 3 is provided with a hollow distance measuring device 4; the inner end of the distance measuring device 4 is provided with a sensing mechanism 5, and the sensing mechanism 5 is connected to the controller; The second guide rail 6, the second guide rail 6 is connected with the first clamping mechanism 9 and the second clamping mechanism 10 through the second slider 7 and the third slider 8, and the first clamping mechanism 9 and the second A push-pull mechanism connected to the controller is provided between the clamping mechanisms 10; a cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com