Air injector for milking plants

A technology of air injectors and equipment, applied in the direction of milking devices, applications, dairy products, etc., can solve the problems of complicated installation, difficulty in obtaining fast movement of membranes, and large external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

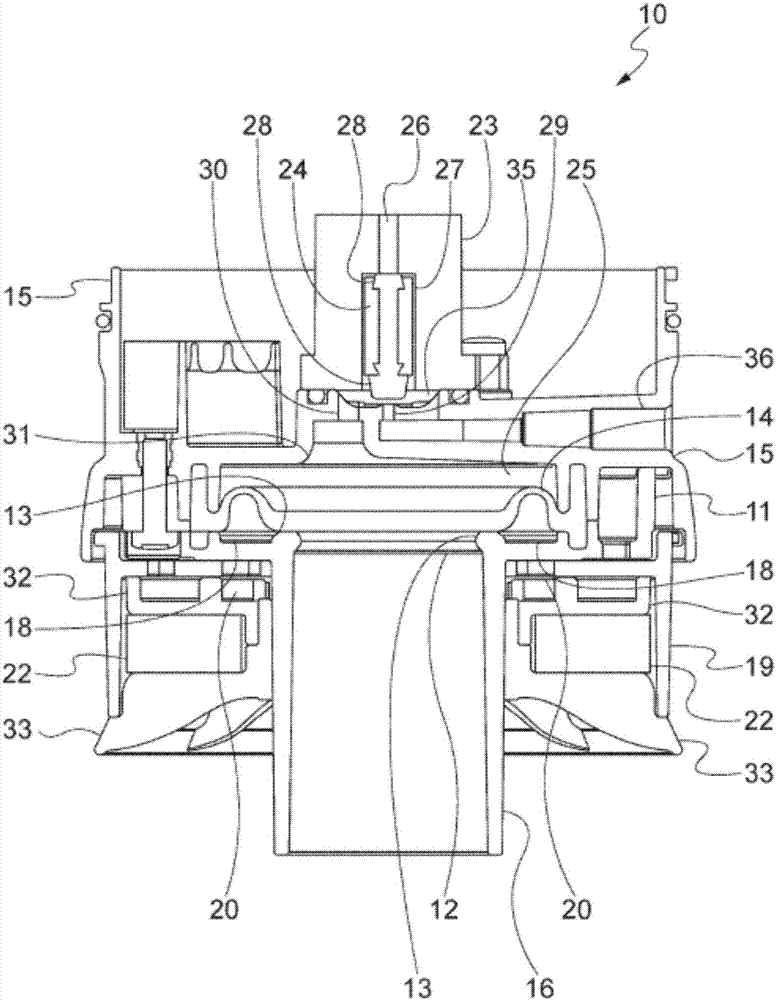

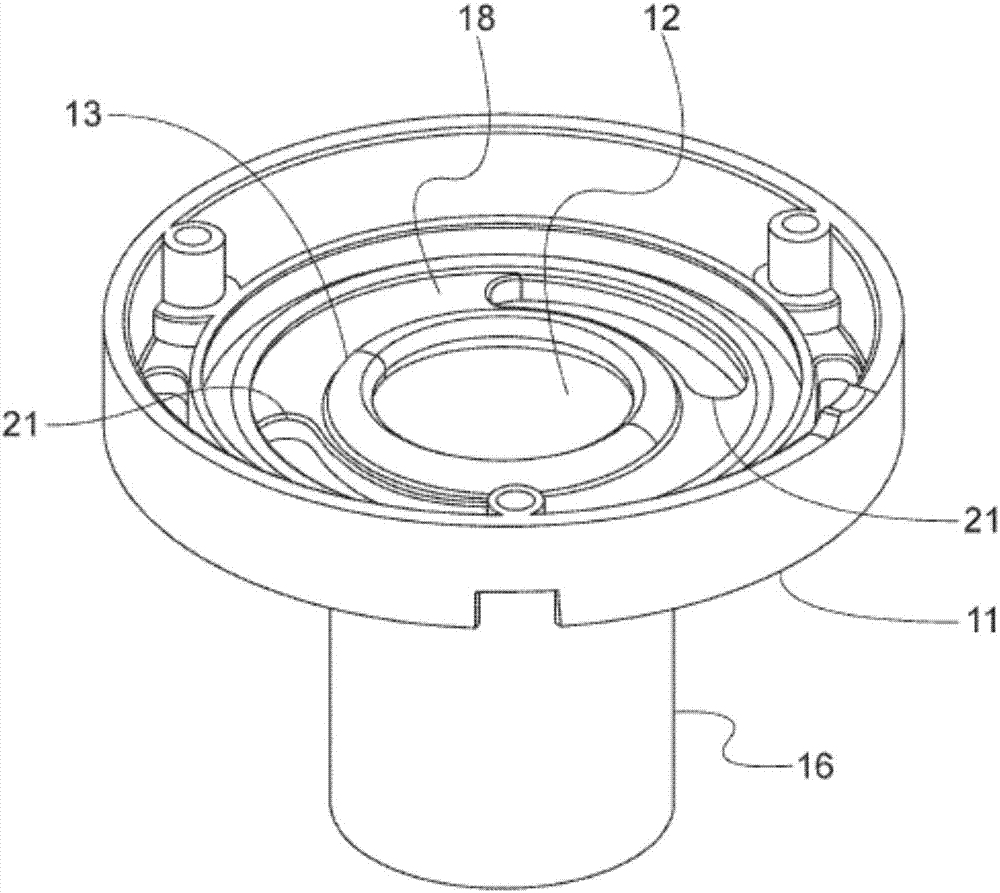

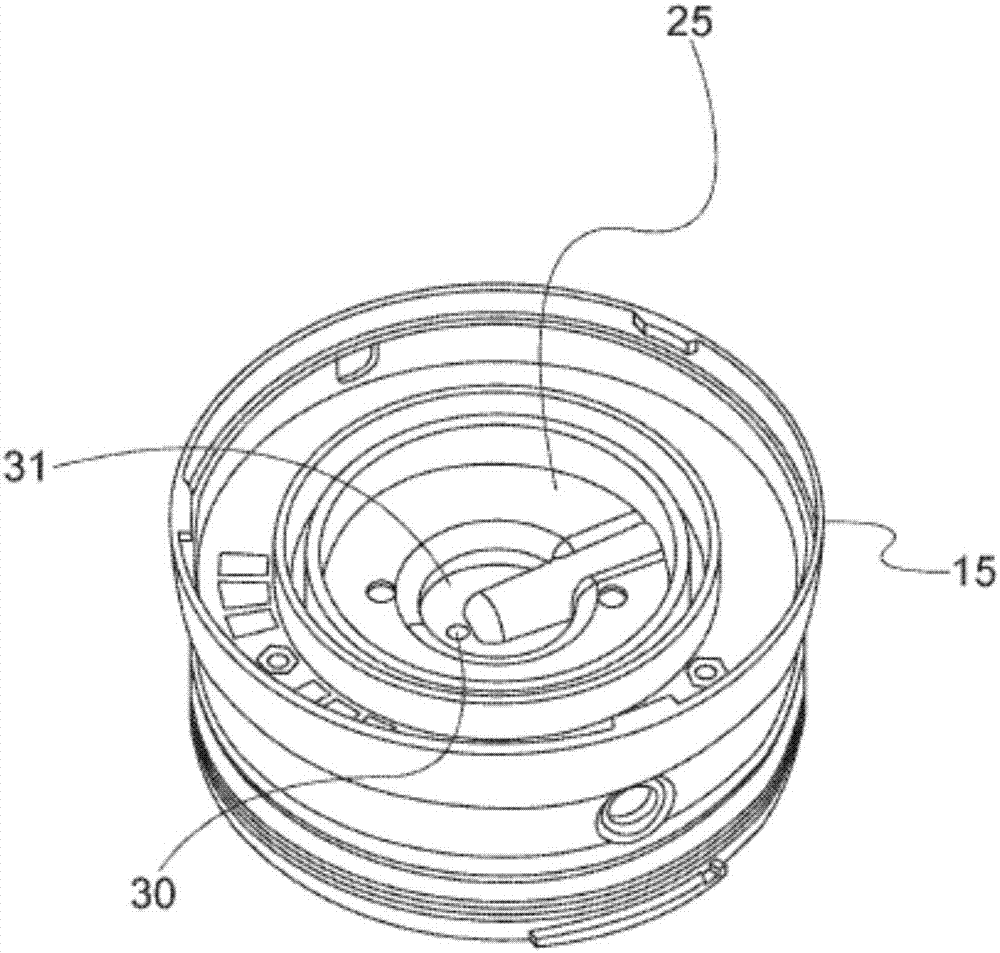

[0022] Referring to the drawings, there is shown an exemplary embodiment of an air injector 10 for a milking apparatus, according to an embodiment of the present invention.

[0023] Said air injector 10 comprises a lower body 11 having an air inlet 12 for introducing air into the device, supported on said air inlet 12 by a membrane 14 and delimited below by said membrane 14 And above a tightly sealed lower chamber 25 defined by an upper body or cover 15, preferably said air inlet 12 has a rounded edge 13 against which said diaphragm 14 rests.

[0024] Said diaphragm 14 is connected to the lower body 11, preferably it is held between said lower body 11 and upper body 15 so as to tightly seal said lower chamber 25, and it is formed in a known manner, For example, made of silicone, with the crimping profile required to allow the diaphragm to develop a stroke in order to open and close the air inlet 12 .

[0025] Said lower body 11 constitutes the supporting structure of said air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com