furniture hinge

A technology for hinges and furniture, applied in the field of furniture hinges, which can solve the problems of high labor costs in construction and manufacturing, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

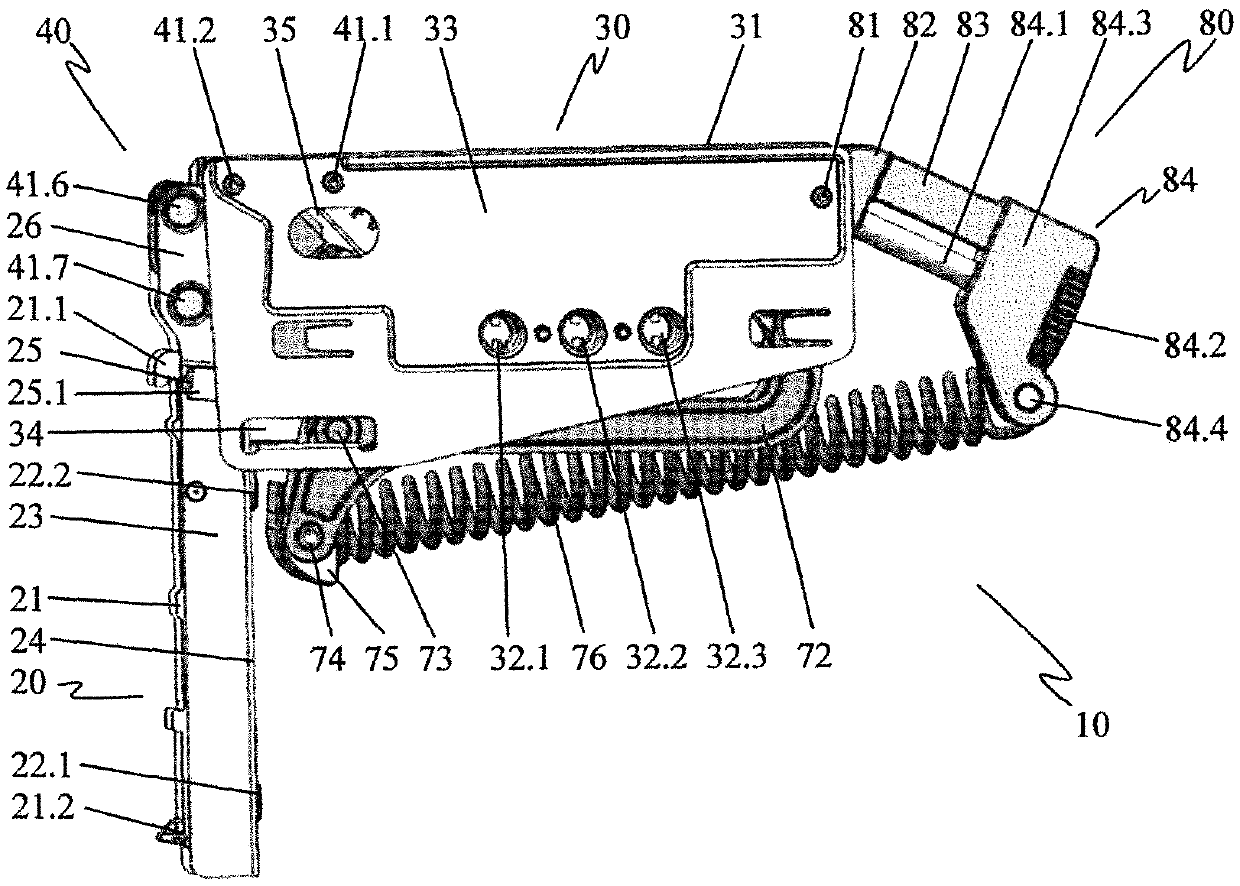

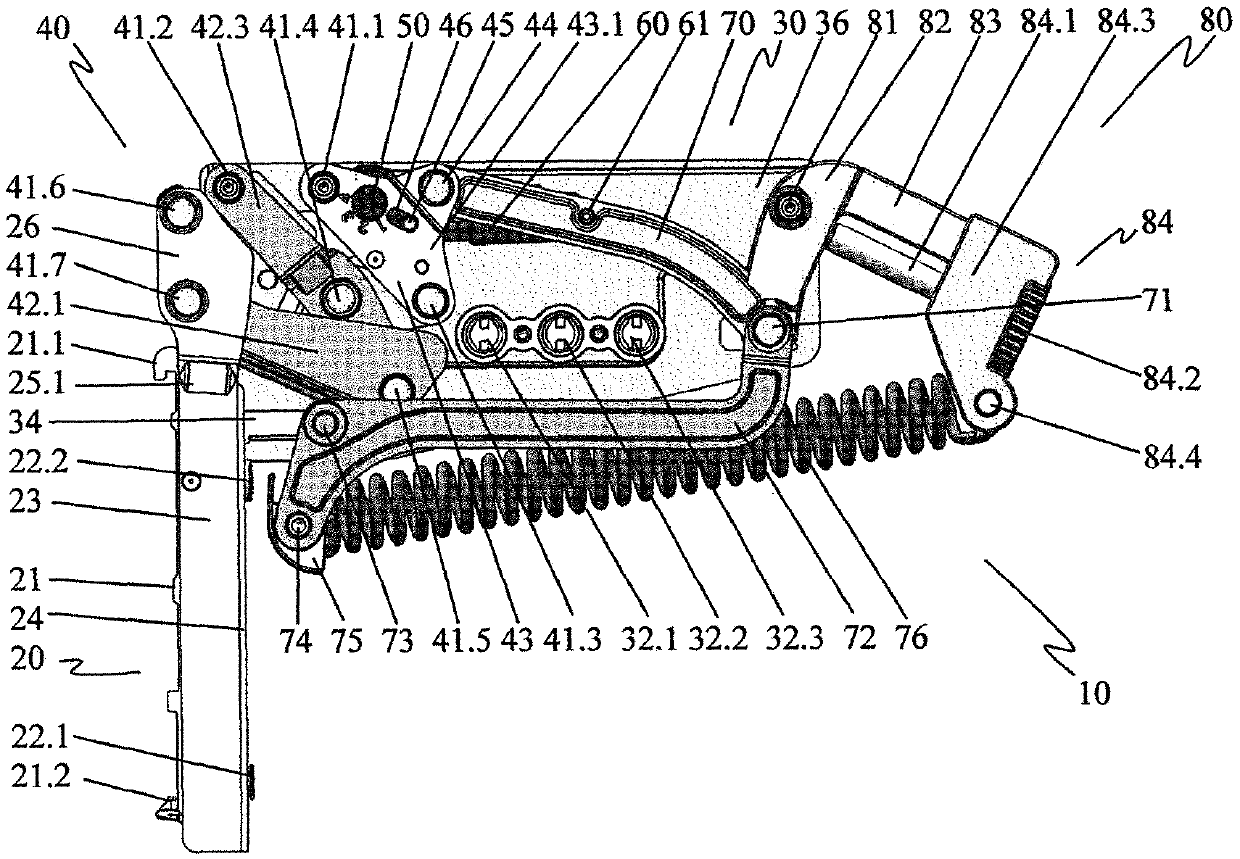

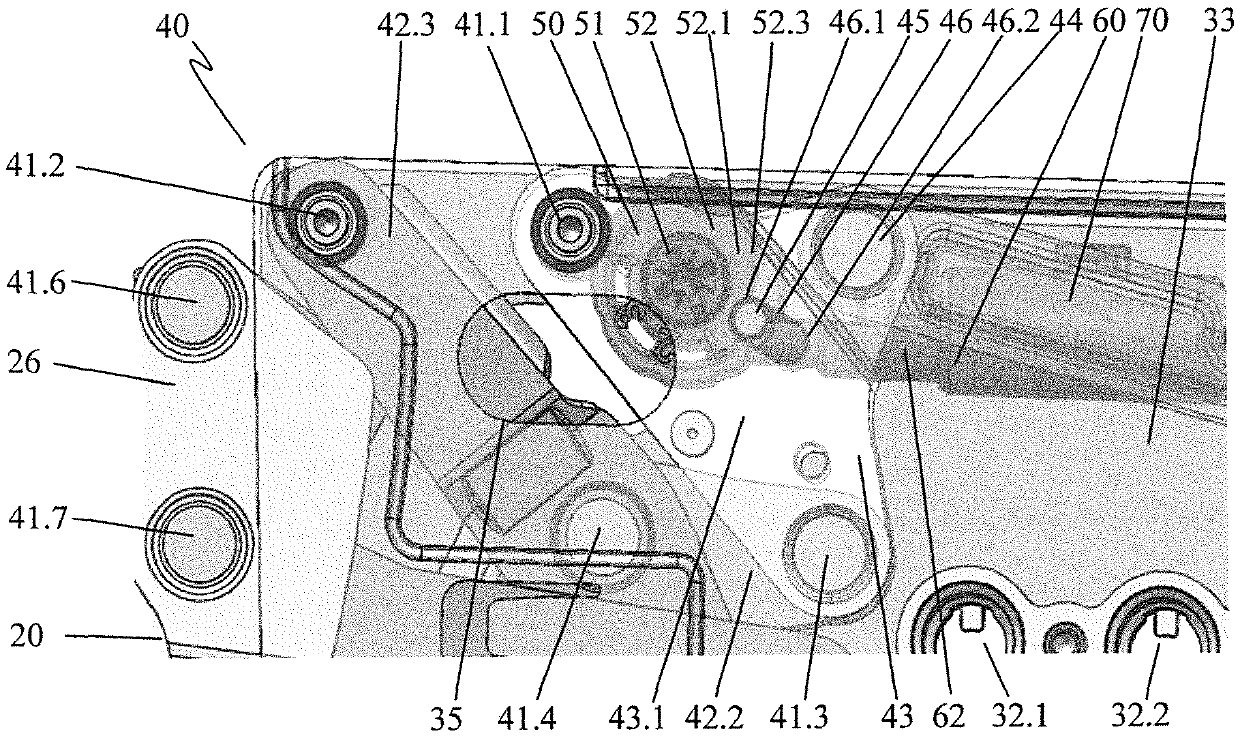

[0033] figure 1 The furniture hinge 10 is shown in a side view with the hinge housing 31 closed in the first end position of the hinge arms 20 folded inward;

[0034] The hinge housing 31 forms the fastening section 30 of the furniture hinge 10 and has three fastening sockets 32.1, 32.2, 32.3. In the illustration, the hinge housing 31 is closed by a housing cover 33 . A linear guide 34 and an adjustment opening 35 are provided as passage openings in the housing cover 33 . The fastening points of the first joint 41 . 1 , the second joint 41 . 2 and the swivel joint 81 sink into the housing cover 33 .

[0035] The articulated arm 20 is pivotably connected to the fastening section 30 via a polyaxial articulation 40 . The first and second set screws 22 . 1 , 22 . 2 are arranged along the rear web 24 of the hinge arm 20 . The transverse leg 23 adjoins the rear web 24 on either side. The hinge arm 20 engages in a connecting element 21 with connecting hooks 21.1, 21.2. Towards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com