Automobile door edge beam decorative sheet machining and positioning device

A technology for automobile doors and positioning devices, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of high processing costs, low adhesion efficiency, high investment costs, etc., and achieves improved convenience and accuracy, simple structure, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

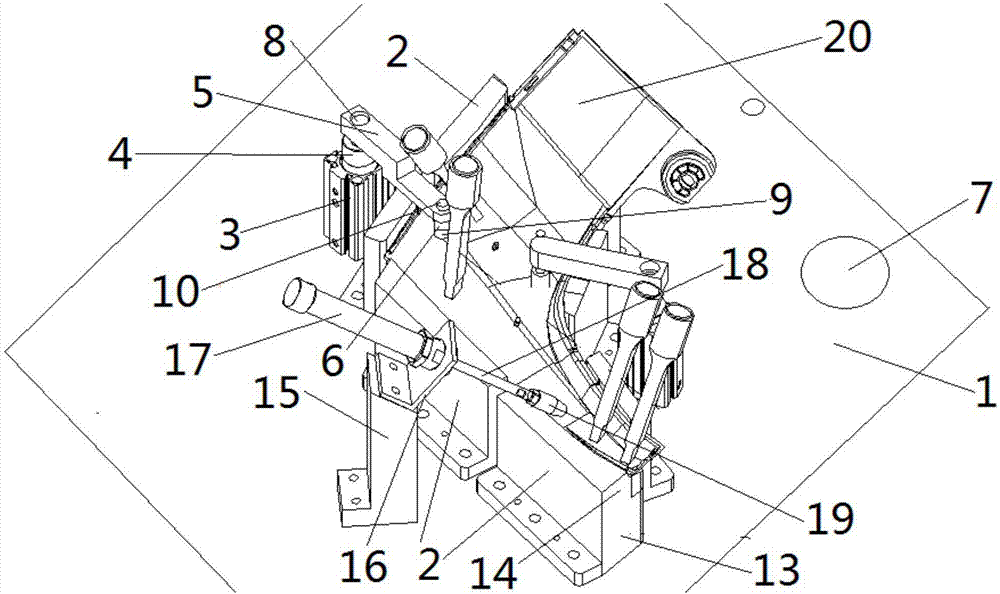

[0017] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

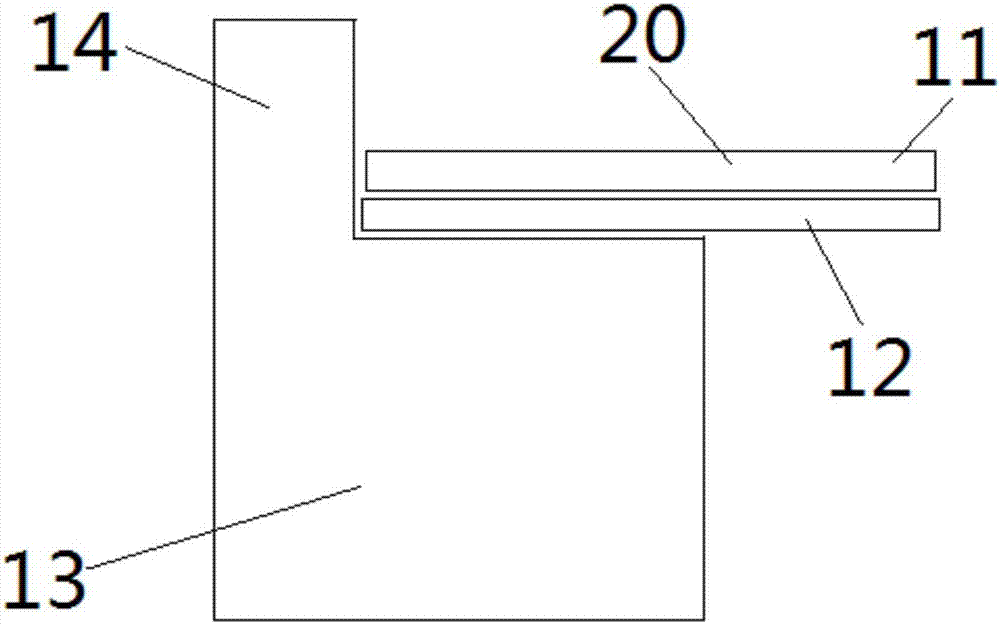

[0018] as attached figure 1 , attached figure 2 As shown, the present invention is a processing and positioning device for an automobile door side sill trim. The automobile door side sill trim includes a side sill trim I11 and a side sill trim II12. The processing of the automobile door side sill trim The positioning device includes a device base 1, on which a plurality of positioning blocks 2 are installed, and a vertically arranged telescopic part I3 is installed on the device base 1, and a connecting rod 5 is installed on the telescopic rod I4 of the telescopic part I3, and a positioning rod 5 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com