A double-cavity quantitative container

A container and container body technology, applied in the field of containers, can solve the problems of wasting health, affecting the user's liquid consumption requirements, and pouring less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

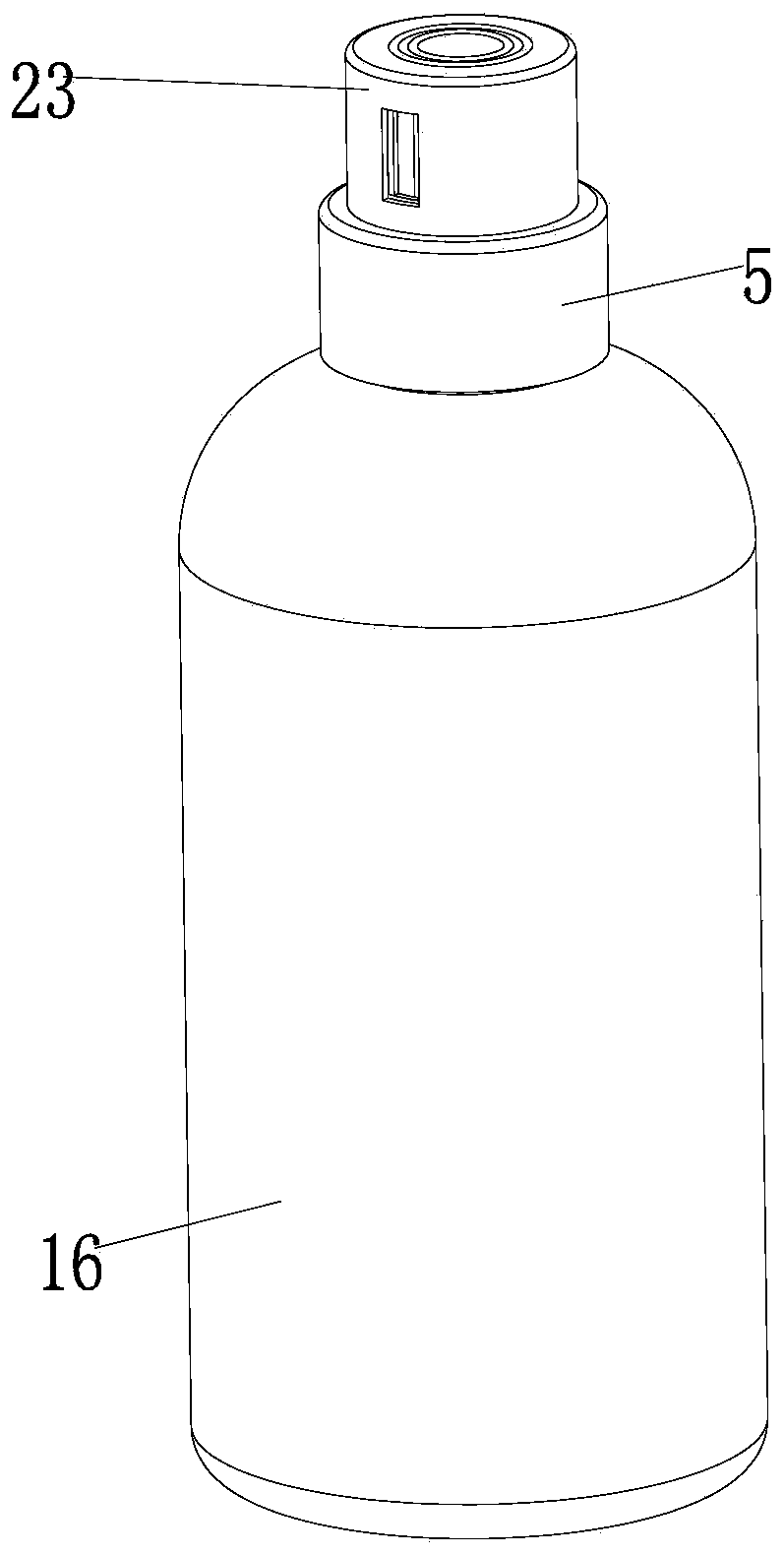

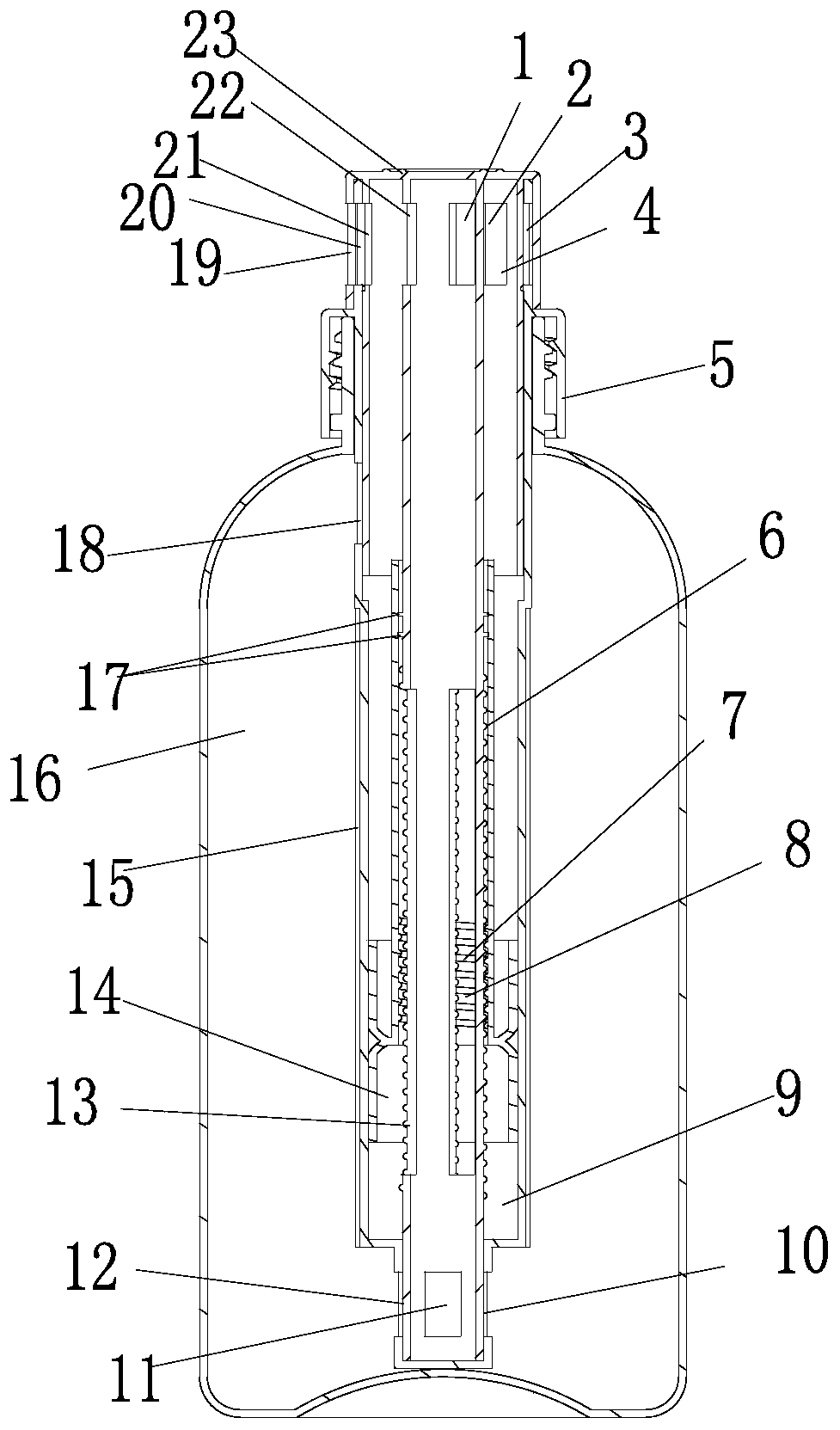

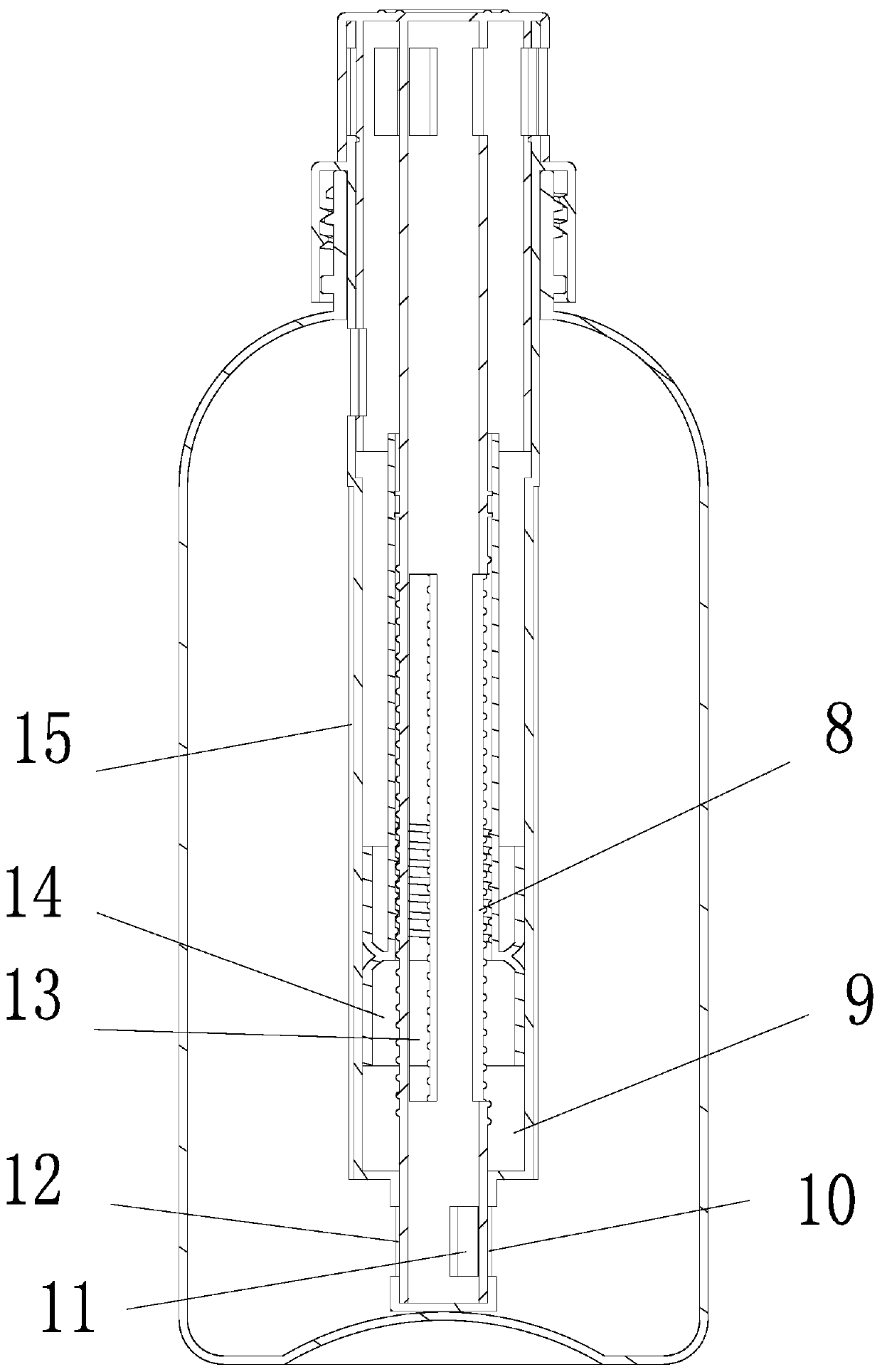

[0028] Embodiment one: refer to Figure 1-Figure 9 As shown: a double-chamber quantitative container is designed, including a container body 16, a seat assembly 5 is fixed outside the neck of the container body 16, and the seat assembly 5 includes a buckle seat connected to the outside of the container neck, It is integrally formed with the buckle seat, and extends into the main pipe 181 at the bottom of the container. A section of the lower part of the main pipe 181 shrinks inwardly to form a short pipe part 121 with a diameter smaller than the main pipe. The bottom of the short pipe part 121 is closed. The side wall of the part 121 is symmetrically opened with an external liquid inlet hole 12, and the top surface of the buckle seat is integrally formed with a jacking pipe 201 connected to the main pipe, and the side wall of the jacking tube 201 is symmetrically opened with a corresponding external liquid inlet hole. The first liquid outlet hole 3 and the second liquid outlet...

Embodiment 2

[0034] Embodiment two, such as Figure 10-15Shown; Provide a kind of double-chamber quantitative container, comprise container body, be fixed with seat assembly 5 outside the neck of described container body, described seat assembly includes the buckle seat that is connected on the outside of container neck, and buckle seat Integral molding, the main pipe extending into the bottom of the container, the bottom of the main pipe is closed, the liquid inlet hole 12 is symmetrically opened on the lower side wall of the main pipe, and the top pipe 201 connected with the main pipe is integrally formed on the top surface of the buckle seat, The side wall of the jacking pipe is symmetrically opened with a first liquid outlet hole 3 and a second liquid outlet hole 20, and a central pipe 113 extending upward to the upper port of the jacking pipe is integrally formed at the bottom of the inner hole of the main pipe. The center pipe and the side wall of the lower section are provided with ...

Embodiment 3

[0037] Embodiment three, such as Figure 16-22 Shown; Design a kind of double-chamber quantitative container, comprise container body, be fixed with seat assembly 5 outside the neck of described container body, described seat assembly includes the buckle seat that is connected on the outside of container neck, and buckle seat Integral molding, the main pipe extending into the bottom of the container, the bottom of the main pipe is closed, the liquid inlet hole 12 is symmetrically opened on the lower side wall of the main pipe, and the top pipe 201 connected with the main pipe is integrally formed on the top surface of the buckle seat, The side wall of the jacking pipe is symmetrically opened with a first liquid outlet hole 3 and a second liquid outlet hole 20, and a central pipe 113 extending upward to the upper port of the jacking pipe is integrally formed at the bottom of the inner hole of the main pipe. On the side wall of the lower section of the central tube, there is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com