Groove wall device and method for making grooves in the ground

A land and trench technology, applied in the direction of excavation, sheet pile wall, earth mover/excavator, etc., can solve the problem that the carrier tool is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

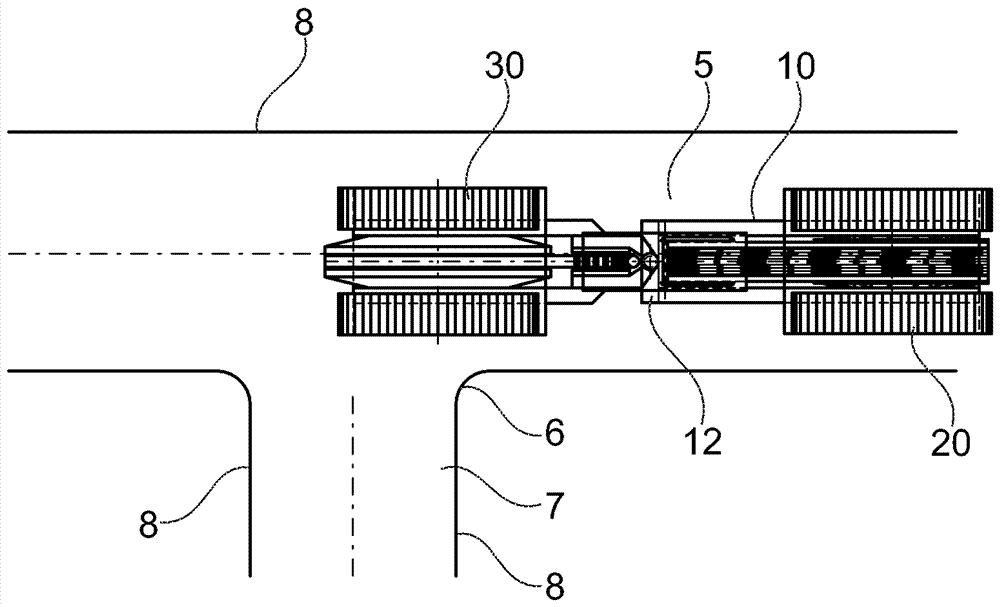

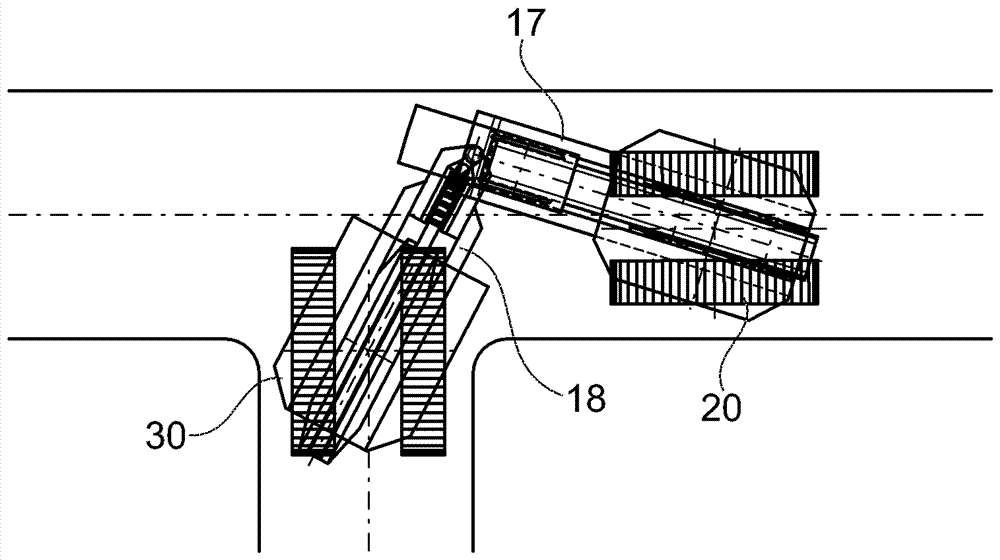

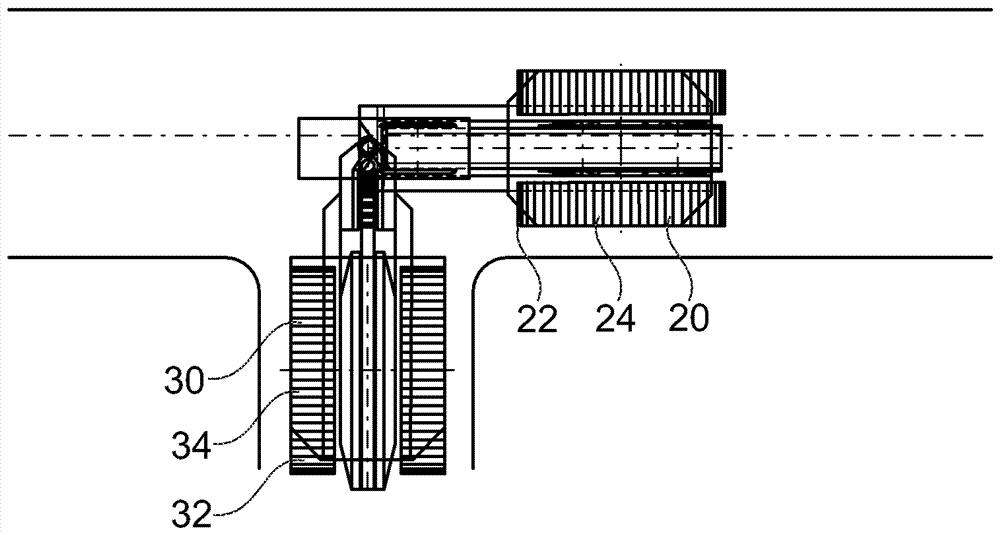

[0030] according to figure 1 with 2The partition wall arrangement 10 has a first carrier tool 20 and a second carrier tool 30 , each of which has a tracked running gear as the lower frame 22 , 32 . A first upper carrier 24 with a frame-like first superstructure 26 is arranged on the first lower carrier 22 via a swivel bearing 23 . Correspondingly, the second upper bracket 34 is rotatably supported on the second lower bracket 32 of the second carrier transport tool 30 via the rotation bearing 33 . A second upper structure 36 similar to a frame structure is fixed on the second upper bracket 34 .

[0031] The first carrier transport means 20 and the second carrier transport means 30 are connected to each other via beam-shaped cross members 12 . To this end, in the upper region of the first superstructure 26 of the first carrier transport 20 is mounted a horizontally protruding first cross member 17 which is coupled via a pivot joint 19 with a vertically directed pivot axis t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com