Concrete pouring device for arch wall lining trolley in single track railway tunnel and mounting method of concrete pouring device

A technology for lining trolleys and single-track railways is applied in the field of concrete pouring devices for lining trolleys for arch walls, and can solve the problems of uneven force on the trolleys, local displacement of the formwork system, and large interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described in detail below.

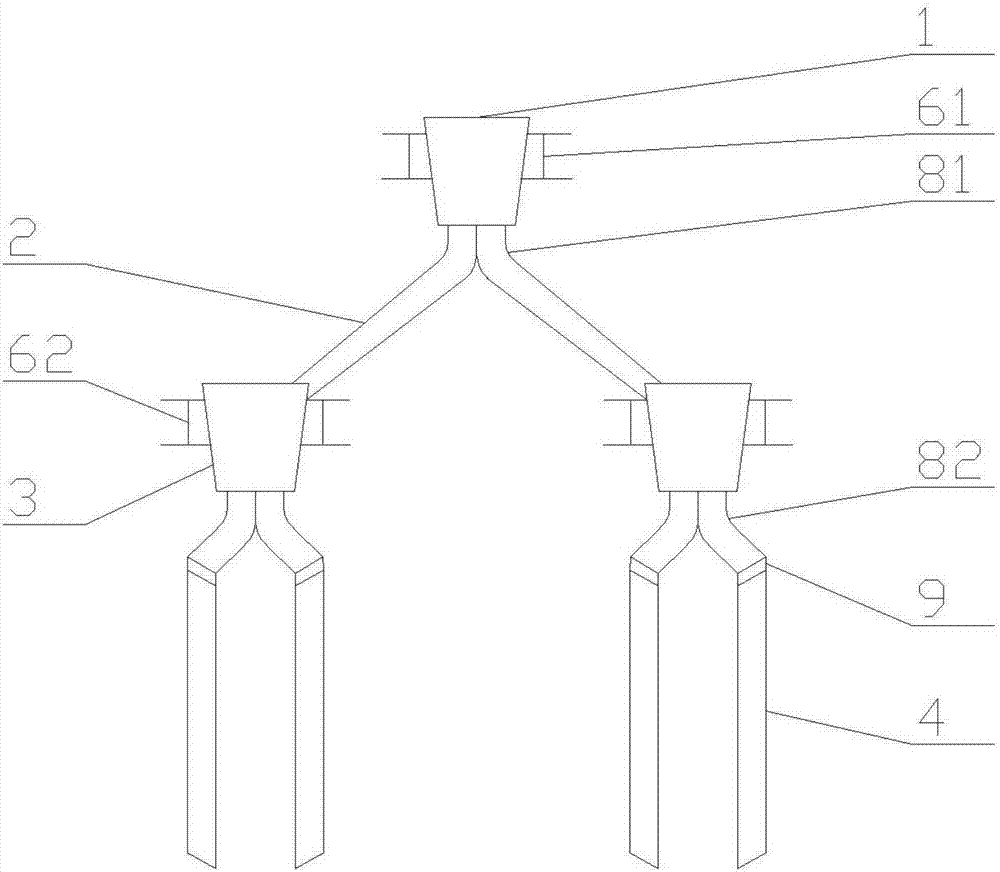

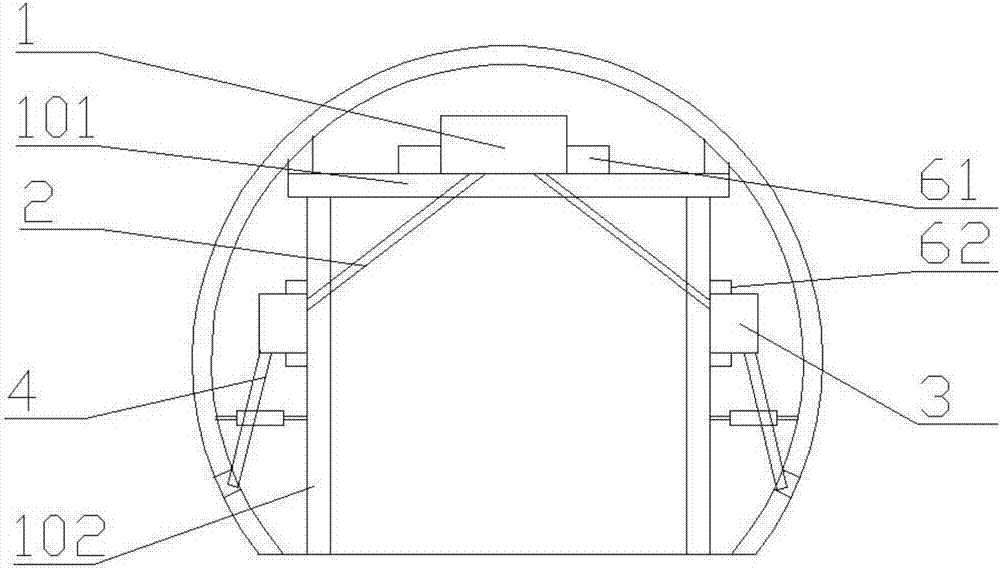

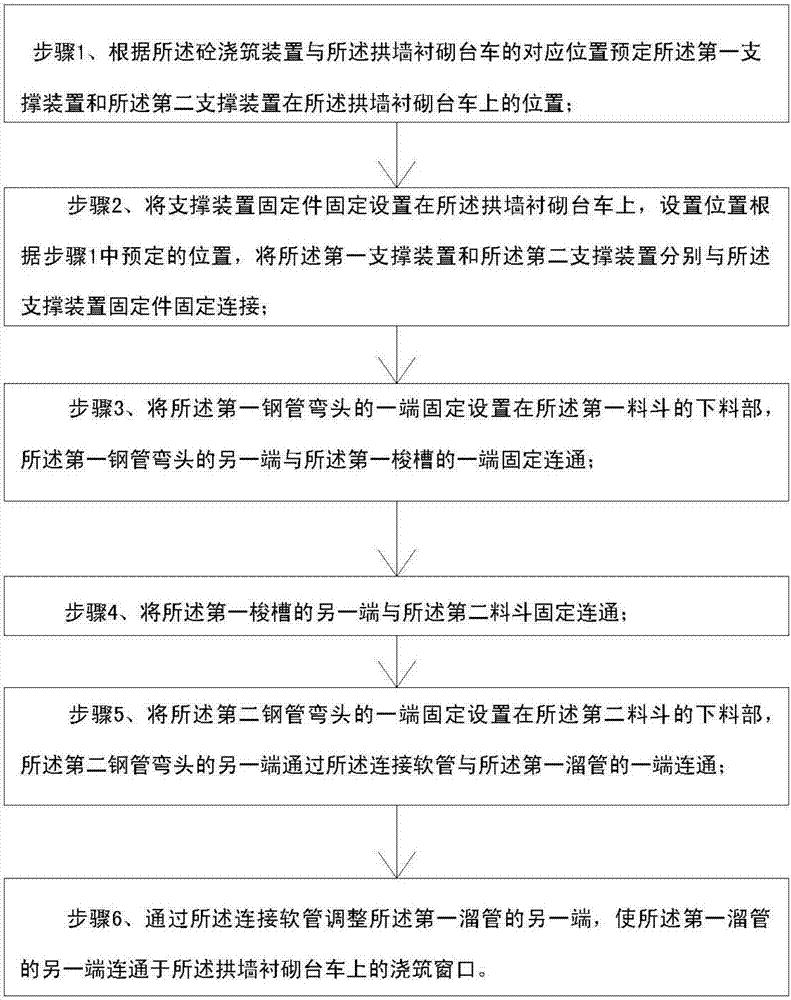

[0033] as attached Figure 1-2 As shown, a concrete pouring device for an arch wall lining trolley in a single-track railway tunnel includes: a first hopper 1, a first support device 61, a first steel pipe elbow 81, a first shuttle groove 2, a second hopper 3, The second support device 62, the second steel pipe elbow 82, the connecting hose 9 and the first chute 4, the first hopper 1 is fixed on the top beam 101 of the arch wall lining trolley through the first support device 61 , the lower part of the first hopper 1 is connected with two first steel pipe elbows 81, the two first steel pipe elbows 81 are symmetrically arranged, and the first steel pipe elbows 81 are connected to the first shuttle slot 2, the first shuttle slot 2 communicates with the second hopper 3, and the second hopper 3 is fixedly arranged on the longitudinal beams 102 on both sides of the arch wall linin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com