Integral elevator counterweight

An integral, elevator technology, applied in elevators in buildings, transportation and packaging, lifting equipment in mines, etc., can solve the problems of high labor intensity, inconvenient installation, complex processing technology, etc., to reduce costs and pollution. , The effect of reducing labor intensity and selecting reasonable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

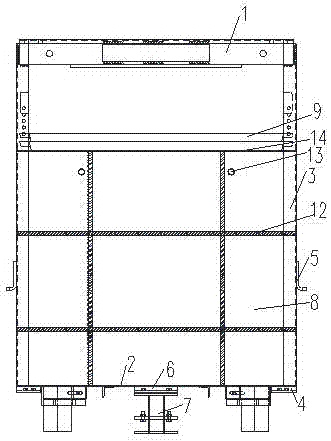

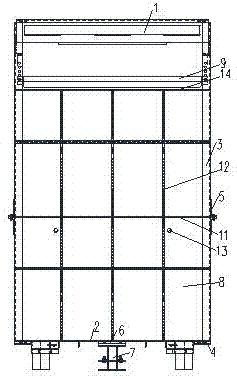

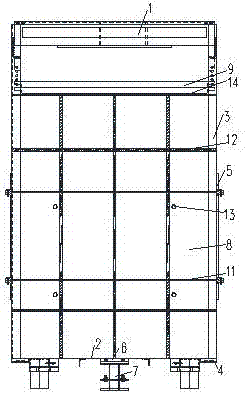

[0017] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] As shown in the figure, the integrated elevator counterweight device of the present invention includes an outer frame, in which a counterweight is installed, and the outer frame includes an upper frame 1, a lower frame 2 and symmetrically arranged two sides. Frame 3, the two side frames 3 are U-shaped steel plates opposite to each other, the width of the side frame 3 is 120-600mm, and the distance between the two side frames 3 is 600-1500mm. Guide shoe seat plates 4 are arranged on both sides of the frame 1 and the lower frame 2, and at least one middle stopper 5 is arranged symmetrically on the outside of the two side frames 3, the middle stopper 5 is L-shaped, and the middle stopper The block 5 is fixedly connected together with the concrete counterweight 8 through the side frame 3, the middle stopper 5 can be arranged in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com