A method for analyzing vibration characteristics of transmission gearboxes in coupled oscillation state

A technology of vibration characteristics and coupled oscillation, applied in special data processing applications, instruments, geometric CAD, etc., can solve the problems of only research, large deviation of vibration characteristics, and no consideration of stiffness excitation and shock resistance, so as to achieve accurate coupling model, Accurate effect of vibration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in more detail below in conjunction with accompanying drawing example:

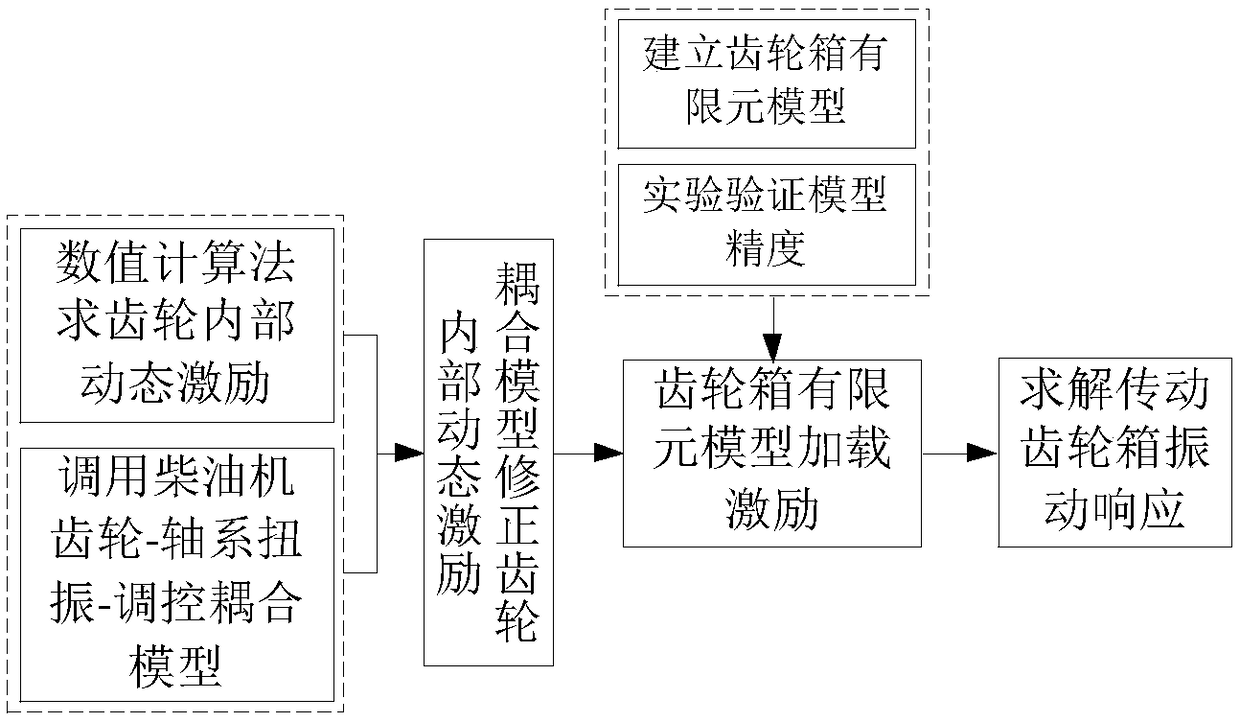

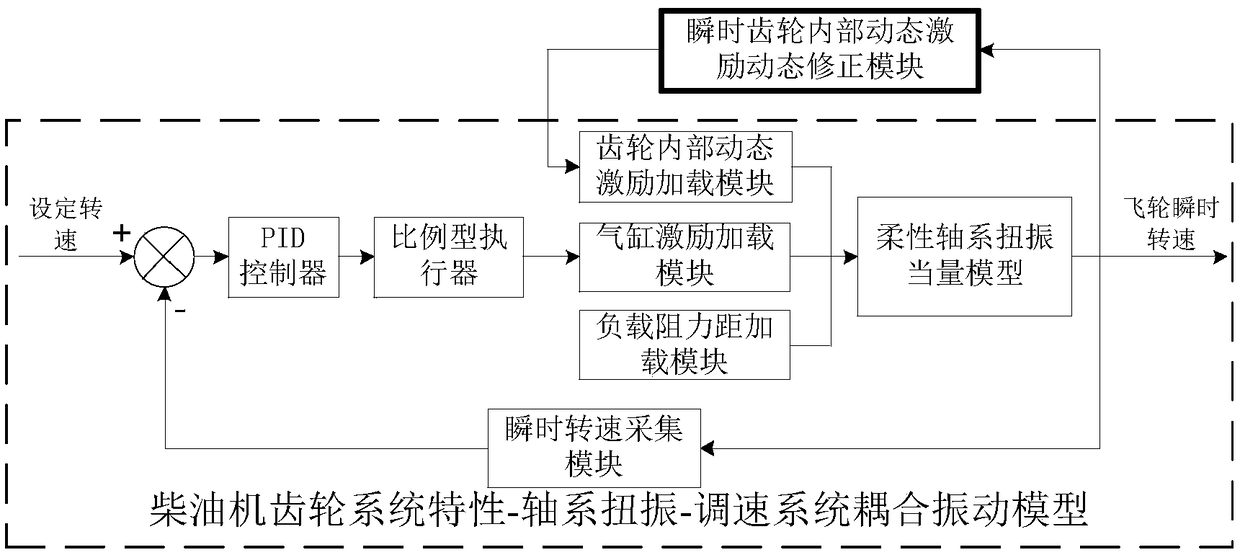

[0038] combine figure 1 , a method for analyzing the vibration characteristics of the transmission gearbox under the coupling oscillation state is realized as follows: firstly, the internal dynamic excitation of the meshing gear pair with periodic characteristics is synthesized by the numerical calculation method under the condition of the set speed; then, the characteristics of the diesel engine gear system -Dynamic correction of the above excitation in the shafting torsional vibration-governing system coupling model; finally, load the corrected excitation to the meshing contact line position of each gear pair in the 3D finite element model of the transmission gearbox to solve the vibration characteristics of the transmission gearbox .

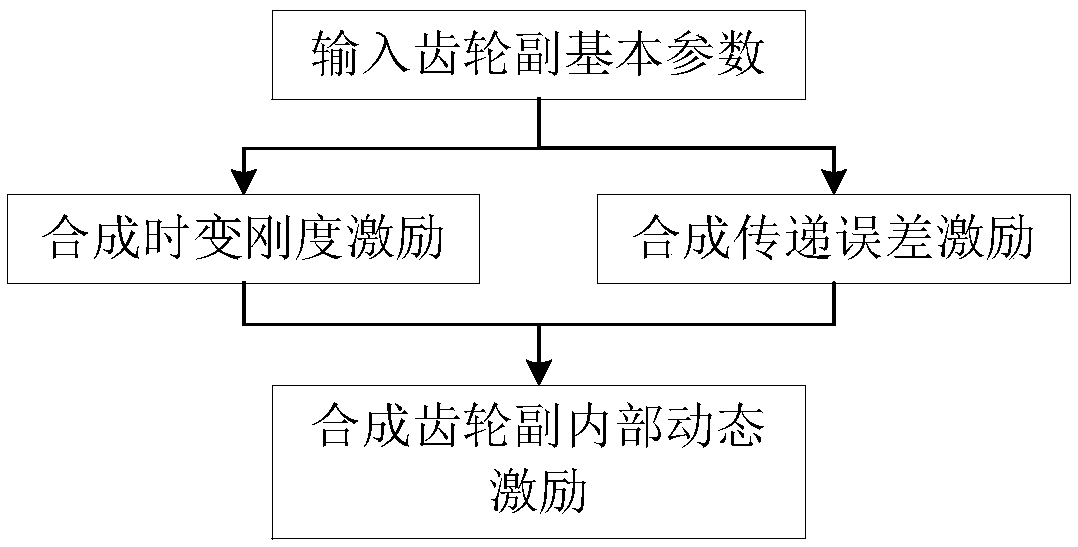

[0039] combine figure 2 , the process of synthesizing the internal dynamic excitation of the gear pair with the traditional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com