Insulator bracket

An insulator and frame technology, which is applied in the field of insulator storage equipment, can solve the problems of troublesome device access, inconvenience in counting the number of composite insulators, affecting the working performance of composite insulators, etc., and achieves the effect of convenient access and convenient access to composite insulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments of the present invention are not limited thereto.

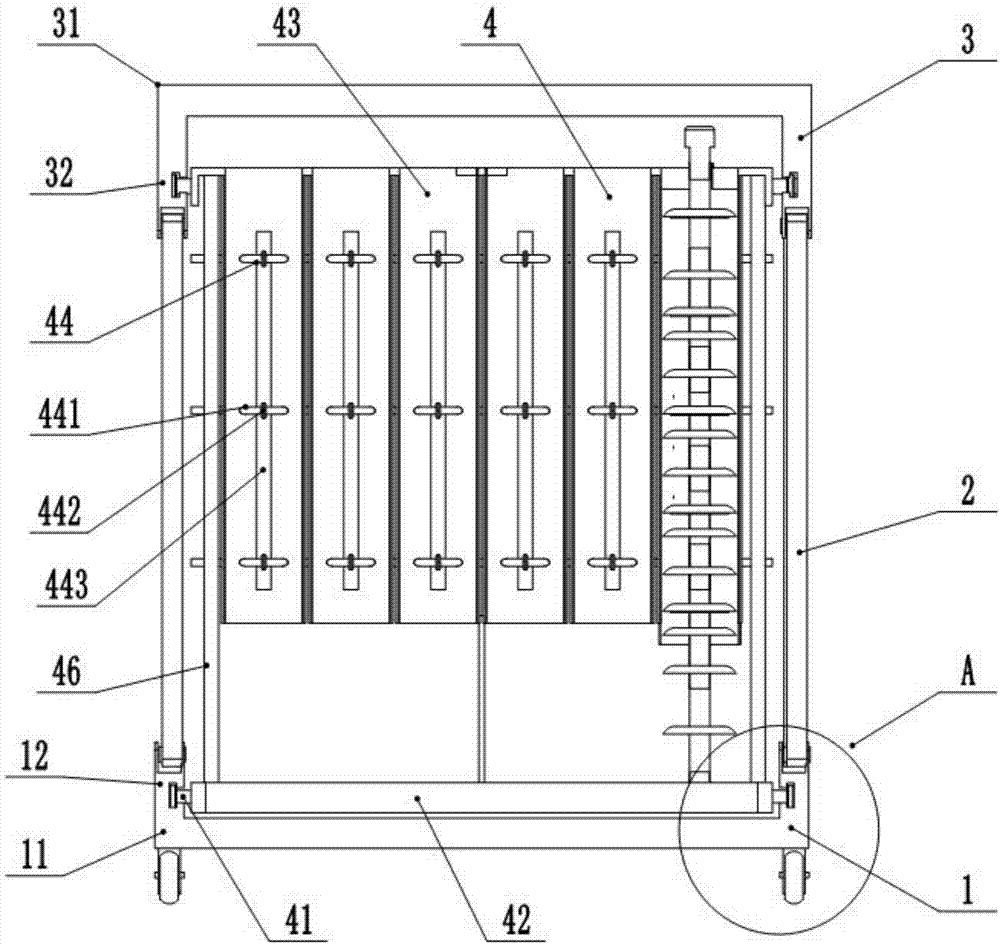

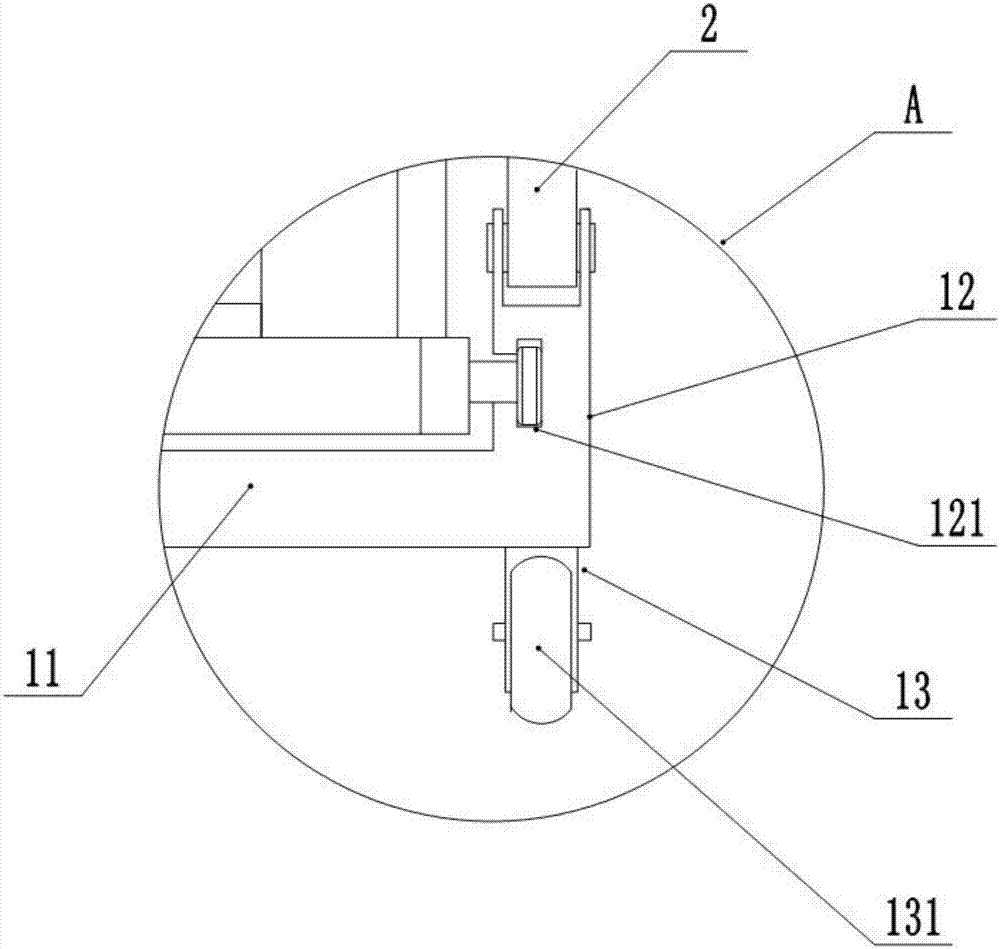

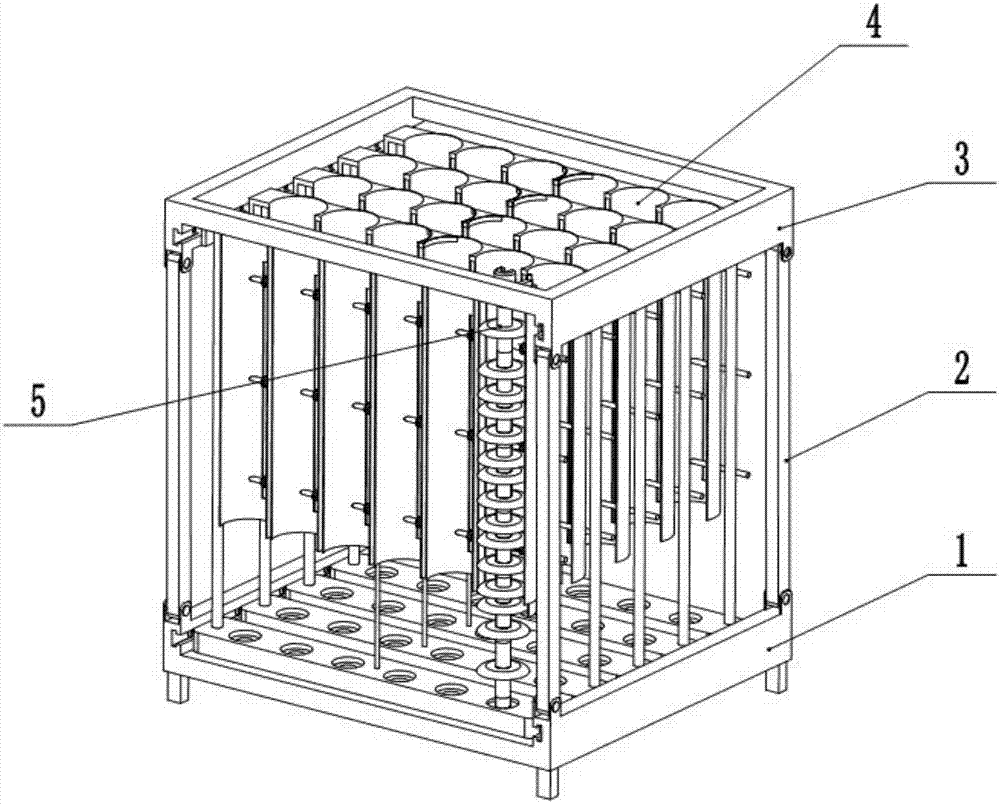

[0030] as attached figure 1 Shown in -6, an insulator support includes a lower support 1, an upper support 3, a column 2 and a storage device 4, the lower support 1 includes a lower frame 11 and a lower vertical plate 12, and the upper support 3 includes an upper frame 31 and The upper vertical board 32, the uprights 2 are arranged on the four corners of the lower vertical board 12 and the upper vertical board 32, the upper vertical board 32 and the lower vertical board 12 are provided with a through chute 121, and the storage device 4 includes a support Plate 42 and arc-shaped plate 43, described arc-shaped plate 43 is connected with support plate 42 by connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com