Pull ring liquid outlet bottle cap

A technology of liquid outlet and bottle cap, which is applied in the direction of capping with auxiliary device, sealing part with unloading device, closing, etc., which can solve the problems of unknown, thick connection, easy-opening, fixing piece falling into the container, etc. problem, to achieve the effect of easy to use and easy to open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

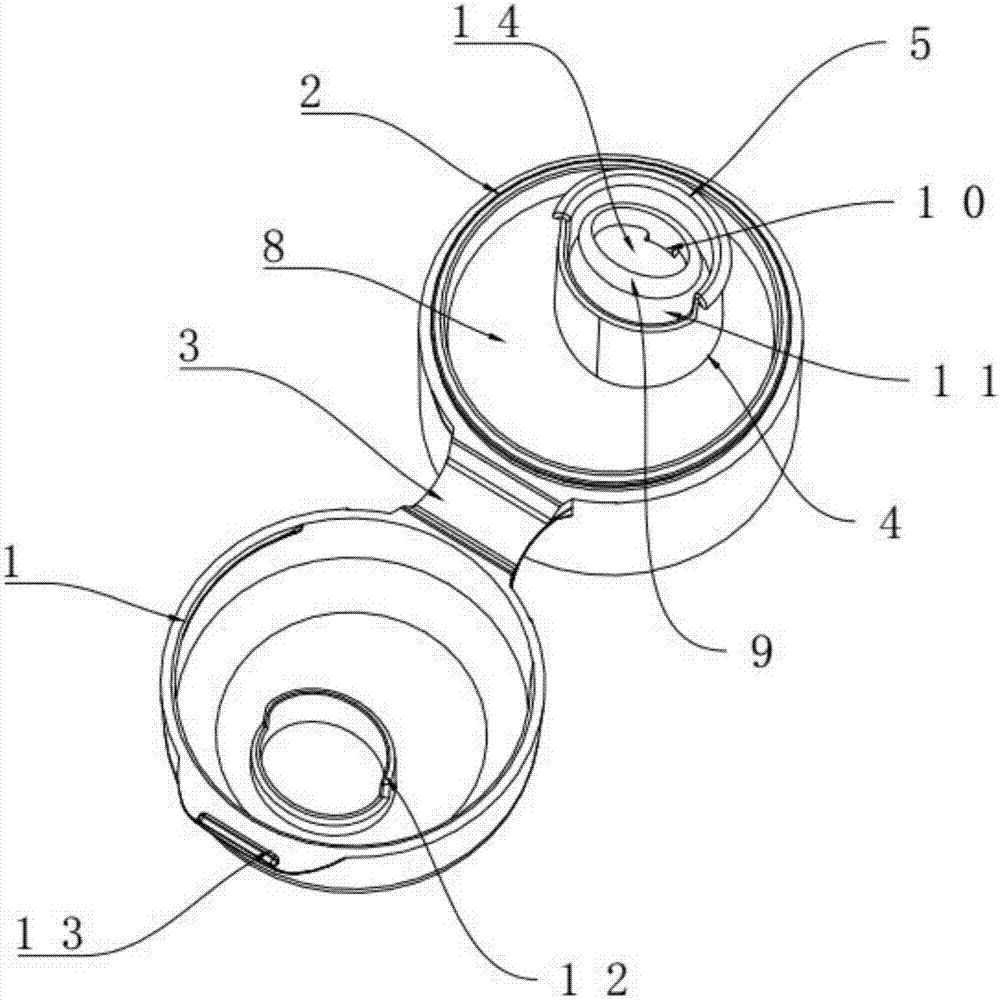

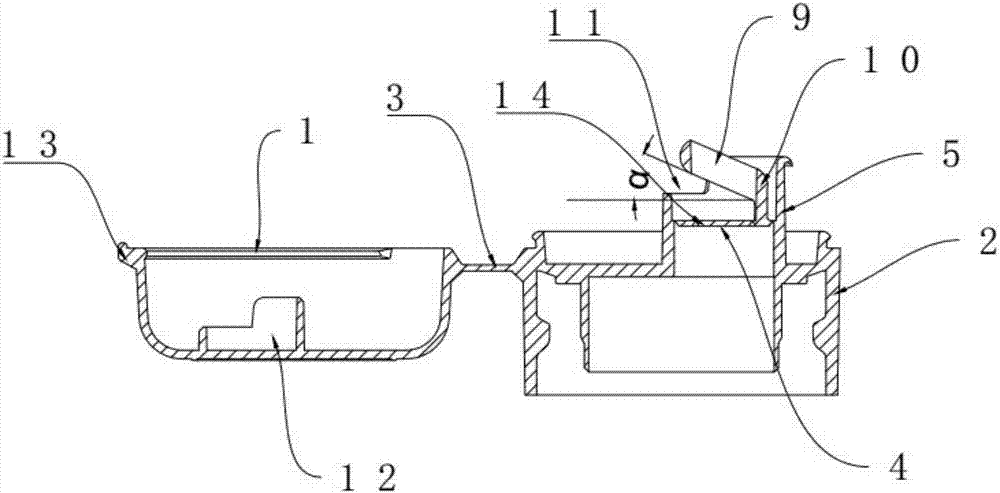

[0025] Such as figure 1 with figure 2 As shown, the pull ring liquid outlet bottle cap includes a buckle cover 1, a cover body 2, a connecting belt 3 and a liquid outlet 4, and the cover body 2 is connected to the side of one end of the buckle cover 1 through the connecting belt 3. wall, the other end of the buckle cover 1 is a free end, the cover body 2 is provided with a spacer 8, the liquid outlet 4 is arranged on the spacer 8, and the liquid outlet 4 is also provided with There is a sealing piece 14, a catheter 5 and a pull ring 9, and one end of the pull ring 9 is connected to the sealing piece 14 by a connector 10 and is arranged in the catheter 5, and the other end of the pull ring 9 One end is a free end, and the catheter 5 is provided with a gap 11 corresponding to the free end of the draw ring 9. If the traditional draw ring method is used, the free end of the draw ring 9 will be placed in the opposite direction of the buckle cover. When the solution is poured aft...

Embodiment 2

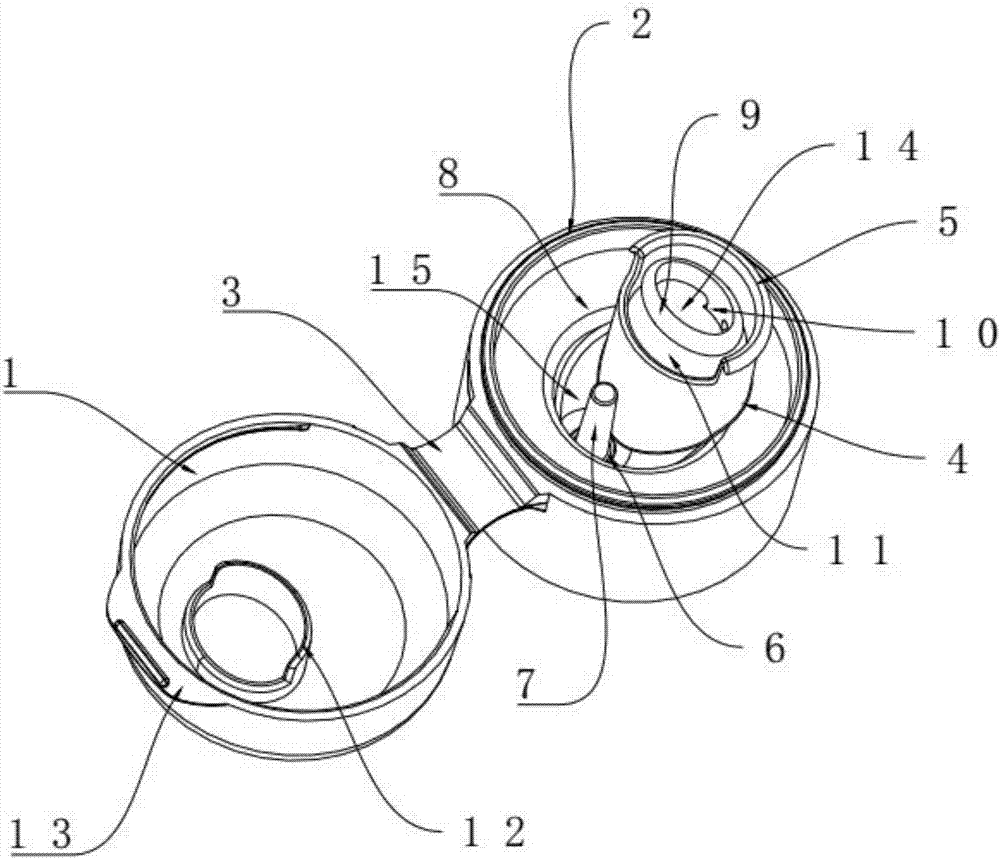

[0033] Such as image 3 , Figure 4 , Figure 5 with Image 6 As shown, on the basis of Embodiment 1, one side of the catheter 5 is provided with a funnel-shaped reflux tank 15, and the bottom of the funnel-shaped reflux tank 15 is provided with an air outlet 6, and the air outlet 6 is provided with a Conical sealing column 7 is arranged. The position of the air outlet 6 on the spacer 8 is lower than that of the liquid outlet 4, which facilitates the backflow of residual liquid and keeps the mouth of the bottle clean and hygienic.

[0034] The height of the catheter 5 is 5 mm to 20 mm; the height of the tapered sealing post 7 is 3 mm to 20 mm. The height of the tapered sealing column 7 is lower than the height of the catheter 5, which is convenient for the closure of the cover 1 and the cover body 2, and prevents the closure from being tight, causing the solution in the container to deteriorate and endangering the health of the diet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com