Pretreatment device and method capable of simultaneously determining hydrophobic and oleophobic characteristics of paper

A pretreatment device, hydrophobic and oleophobic technology, applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve problems such as large experimental errors, complicated operations, affecting the work efficiency and initiative of operators, and avoid manual errors and cumbersome steps, improve accuracy and experimental efficiency, and accurately measure the effect of hydrophobic and oleophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

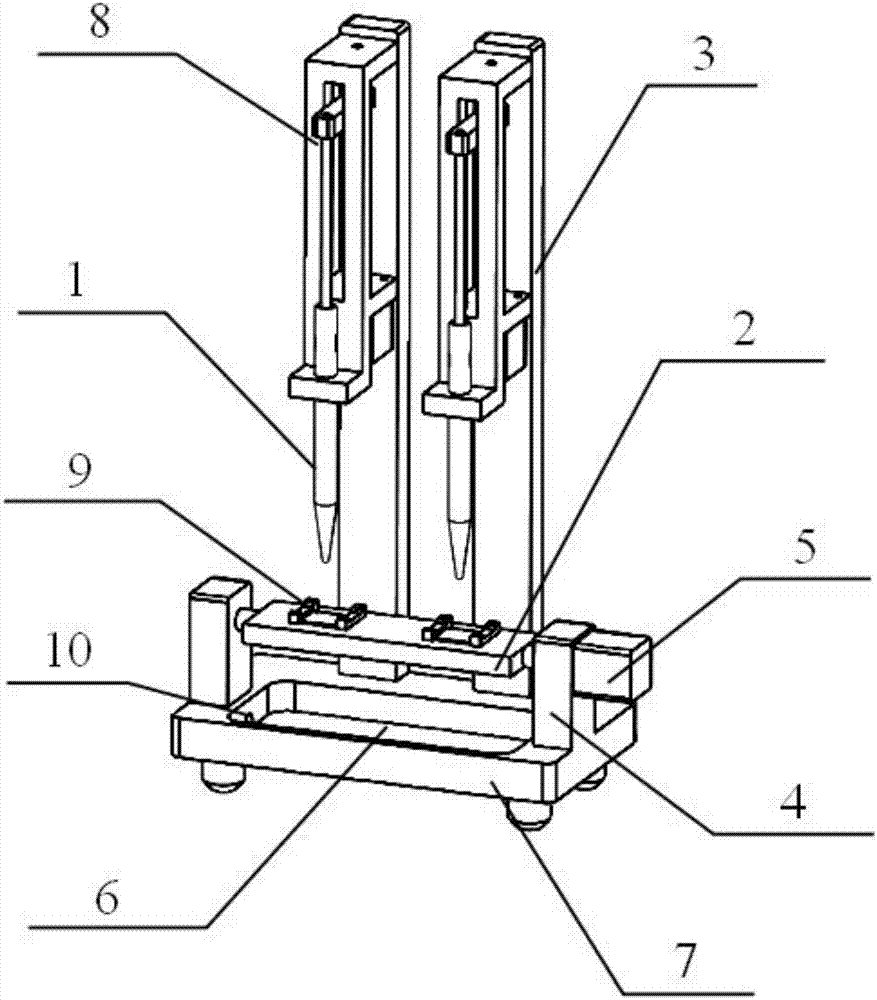

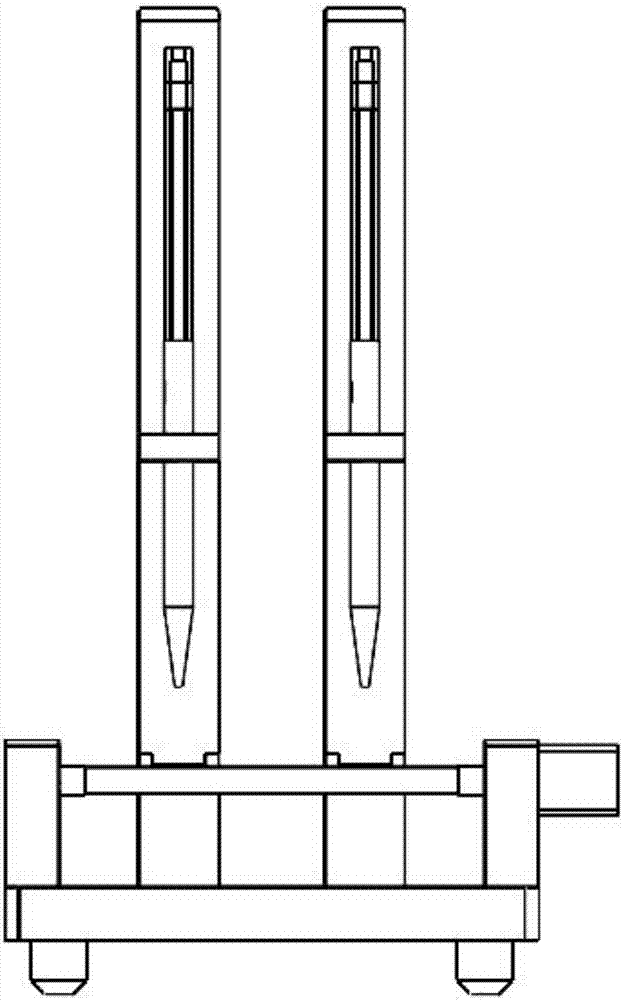

[0035] Such as figure 1 , 2 shown. The invention discloses a pretreatment device for simultaneously measuring the hydrophobic and oleophobic properties of paper, which comprises the following components:

[0036] Two sample needles 1 with the same structure;

[0037] Sample stage 2;

[0038] Two sample needle mounting brackets 3 with the same structure;

[0039] Base 7;

[0040] The two sample needle mounting brackets 3 are respectively parallel and vertically fixed on the base 7;

[0041] The two sample needles 1 are respectively fixed on the two sample needle mounting brackets 3;

[0042] The sample stage 2 is located below the two sample needles 1, and its two ends are respectively installed on the base 7 through the support frame 4;

[0043] On the surface of the sample stage 2 , corresponding to the lower part of the two sample needles 1 , there is provided a slot 9 for fixing the sample. The specific shape, specifications and dimensions of the card slot 9 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com