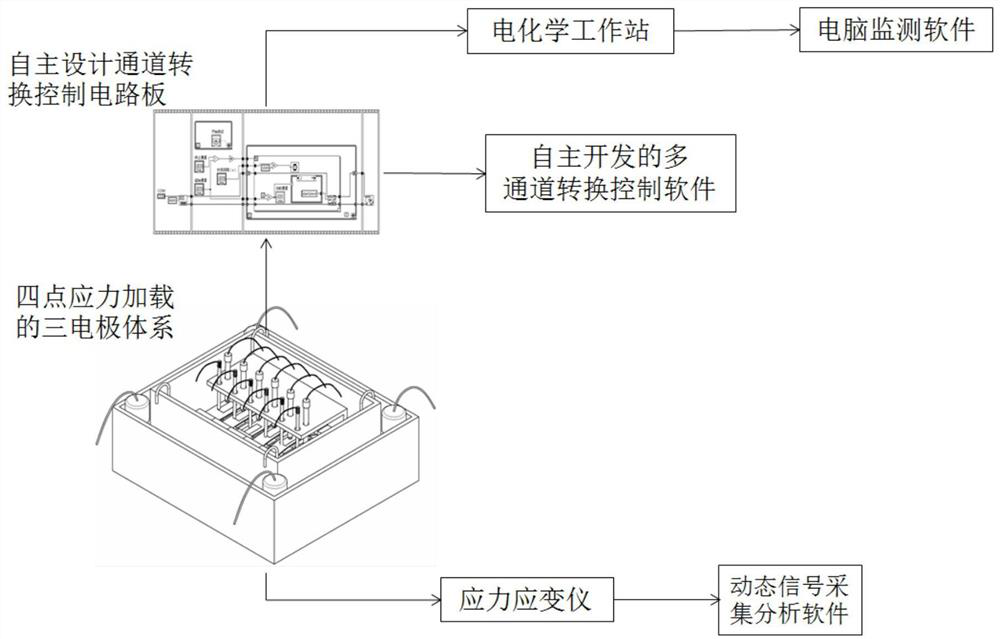

Multi-channel corrosion monitoring system suitable for studying stress corrosion of metallic materials

A technology of stress corrosion and metal materials, applied in the field of multi-channel corrosion monitoring system, can solve the problems of inability to accurately evaluate the corrosion state of ships and marine engineering structures, increase the difficulty of monitoring system design, and high labor costs of equipment, and achieve improved stress loading methods , Improve experimental efficiency and accuracy, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

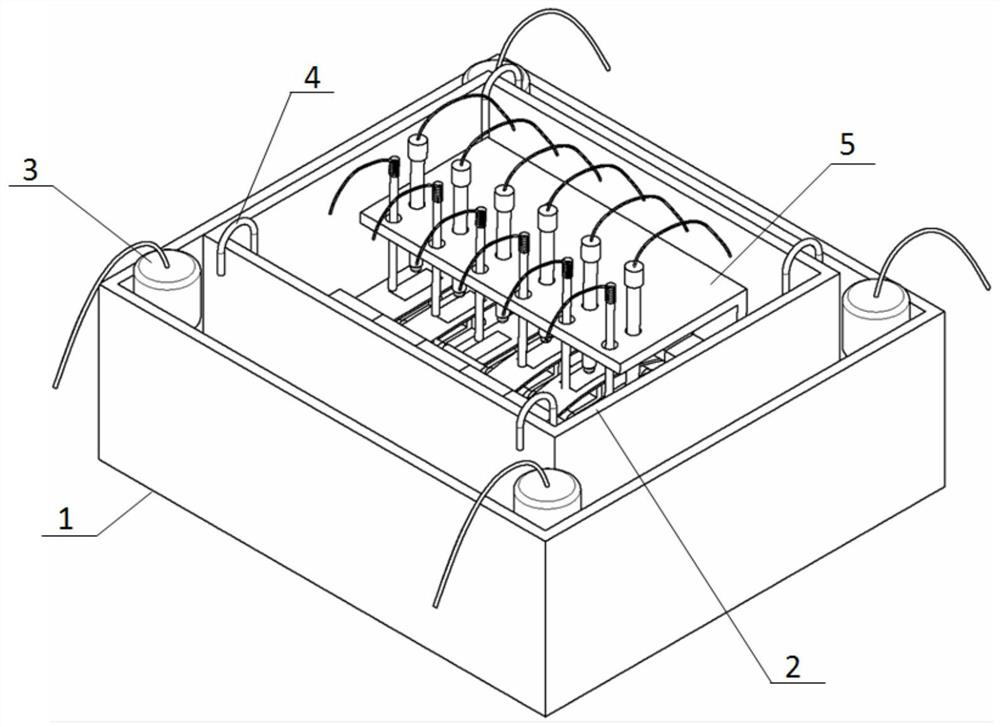

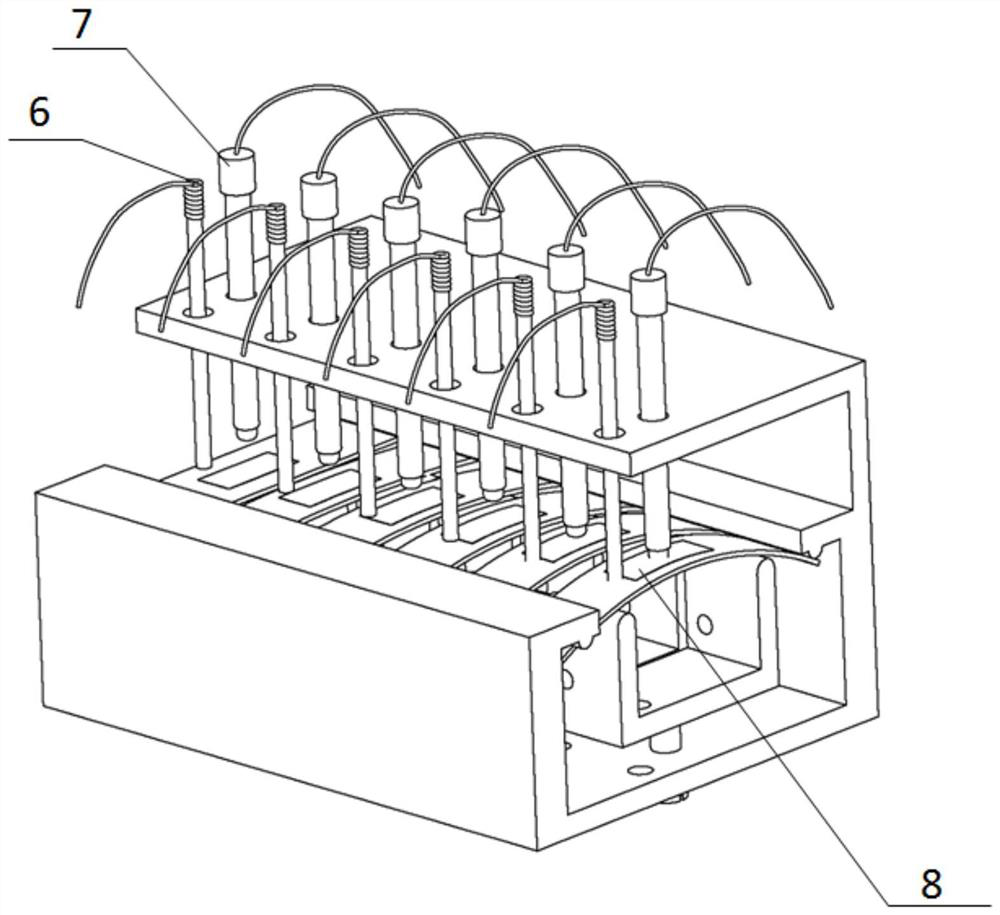

[0024] like figure 2 As shown, first Figure 2-2 The sample 8 shown is placed on the four-point stress load device 5, and the size of the electrode 7 and the counter electrode 7 and the counter electrode 6 are arranged by the bolt adjustment of the device. Placed in the electrolytic liquid tank 2, and adding a modified electrolyte in the experimental box, the four angles of the electrolytic liquid tank are placed on the air pump, respectively, to ensure the oxygen content of the electrolyte environment. The electrolytic liquid tank is placed in a water bath, and the four angles of the water bath box places a heating rod to control the temperature of the water in the water bath.

[0025] Sample 8 surface paste strap 10 passed through the wire figure 1 The stress strain gauge shown is connected, and the dynamic signal acquisition analysis software in the computer is adjusted to achieve real-time monitoring of stress after initial parameters of stress strain gauges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com