Unit module-assembled and disassembled assembly jig

A unit module and tire frame technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of difficult transfer, large span, low assembly efficiency, etc., and achieve the effect of rapid assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is described in further detail.

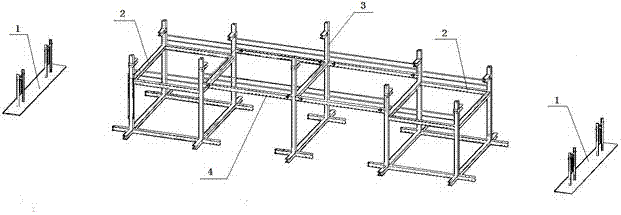

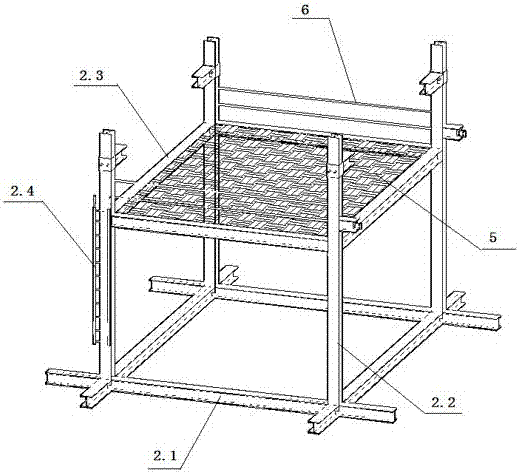

[0016] see figure 1 , the present invention relates to a unit modular assembly and disassembly type assembled tire frame, comprising two unit modules 1, two unit modules 2 and one unit module 3, and the two unit modules 2 are symmetrically arranged on the unit module 3 On both sides, the three are connected by section steel connecting beams 4 to form an overall frame. Bolt nodes 8 are used at the connection nodes. The section steel on the two unit modules 2 and between the unit module 2 and unit module 3 A wooden springboard 5 is laid on the connecting beam 4, and a safety rope 6 is hung.

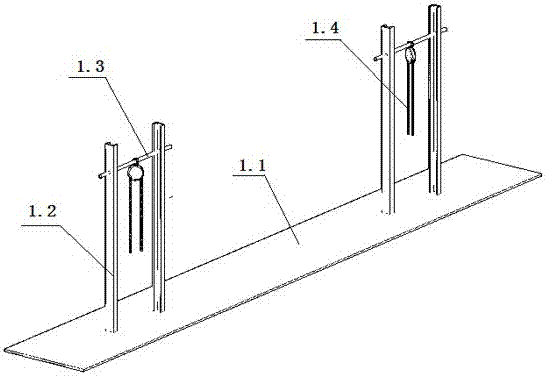

[0017] like figure 2 As shown, the unit module one 1 includes a steel base plate 1.1 and two pairs of channel steel columns 1.2 welded on both sides of the steel base plate 1.1, and a steel bar 1.3 is provided through a round hole opened between each pair of channel steel columns 1.1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com