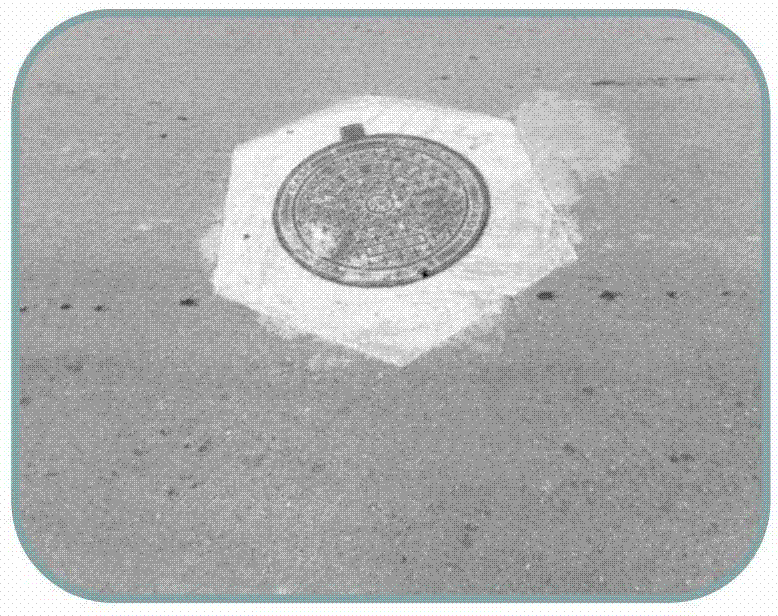

Black high-strength concrete pouring material for rapid repairing of city road inspection well

A high-strength concrete and pouring material technology is applied in the field of new pavement materials, which can solve the problems that concrete materials cannot meet the functional requirements of asphalt pavement inspection wells for quick repair, affect road aesthetics, and have a large black and white difference, and achieve good pavement application. effect, to prevent circumferential cracks or chipping, to improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

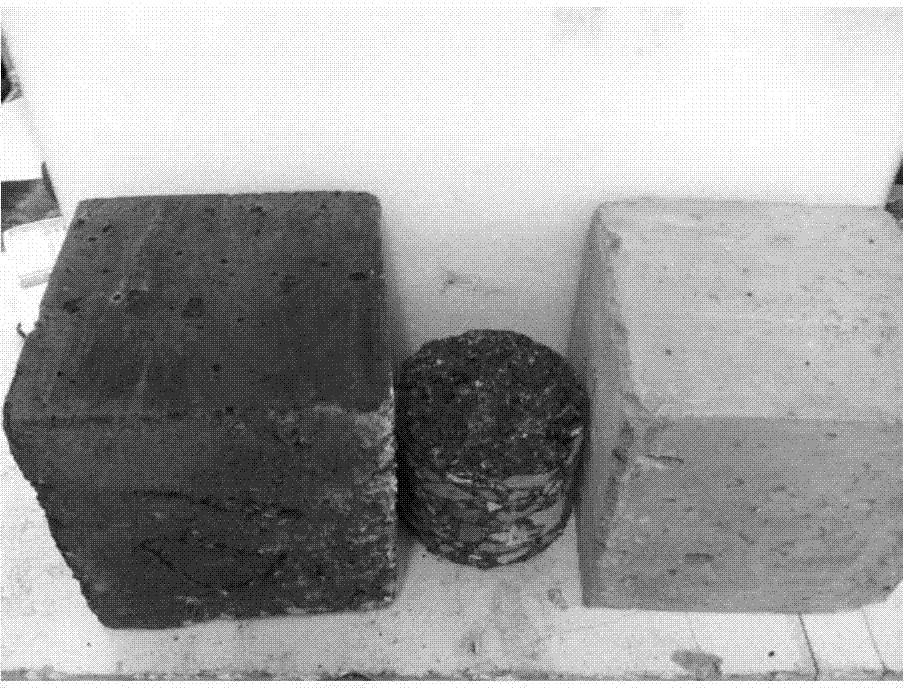

[0044] Embodiment 1 (laboratory preparation):

[0045] A black high-strength concrete pouring material used for quick repair of urban road inspection wells, the laboratory preparation steps are as follows:

[0046] A. Raw material preparation: Leiante CA-50 aluminate cement; natural river sand with a fineness modulus of 3.0 (produced in Bahe, Hubei); limestone crushed stone with a particle size range of 5-10mm continuous grading (produced Hubei Hong’an); Wuhan Hansen Steel Fiber Co., Ltd. produces steel plate shearing steel fibers of the type SFB-20-60; sika’s ViscoCrete20HE polycarboxylate superplasticizer; water is tap water; iron black powder and There are no special requirements for silica fume. In this embodiment, Shuguang brand iron oxide black and Wuhan Xinbida silica fume are used.

[0047] B. Determination of the moisture content of the sand is carried out by drying. The moisture content of the stone is 0, and the moisture content of the sand is 1.2%.

[0048] C. We...

Embodiment 2

[0060] Embodiment 2 (on-site preparation):

[0061] A. Construction preparation: Clean up around the well circle of the inspection well on the pavement that needs to be poured.

[0062] B. Material preparation: use the same ratio and raw materials as the laboratory preparation method in Example 1 for construction, and each raw material can be used after passing the test. Take aggregates from different parts to retest the water content. The retested stone water content is 0, and the sand water content is 1.4%, and adjust the water consumption accordingly. According to the ratio, electronic platform scales are used to measure raw materials, and the amount of concrete is calculated according to the size of the well circumference. The calculated amount of concrete required for each well circumference is about 0.251m 3 , the concrete volume of a group of flexural specimens is 0.037m 3 , considering a certain affluence factor, increase the amount of concrete pouring material to 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com