Single-pump, single-well, two-stage concentration adjustment weak base three-way injection device and its application method

An injection device and concentration technology, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of large viscosity loss and large concentration error, so as to reduce the risk of failure, reduce concentration error, and reduce viscosity loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

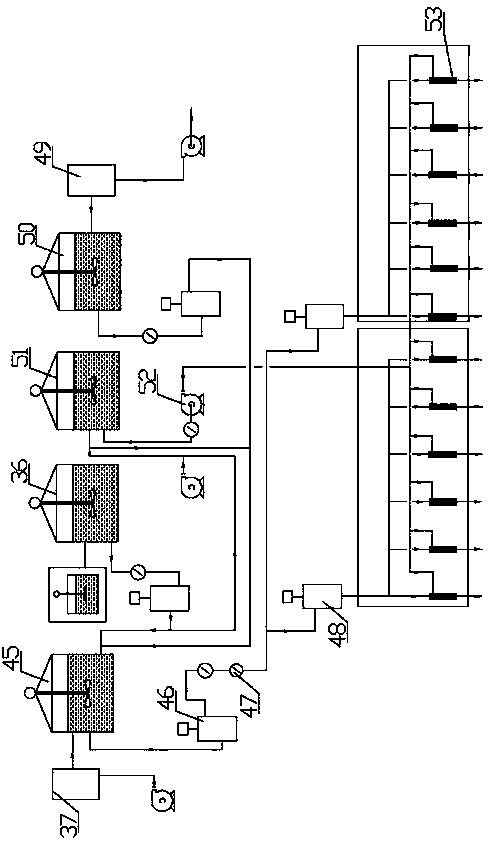

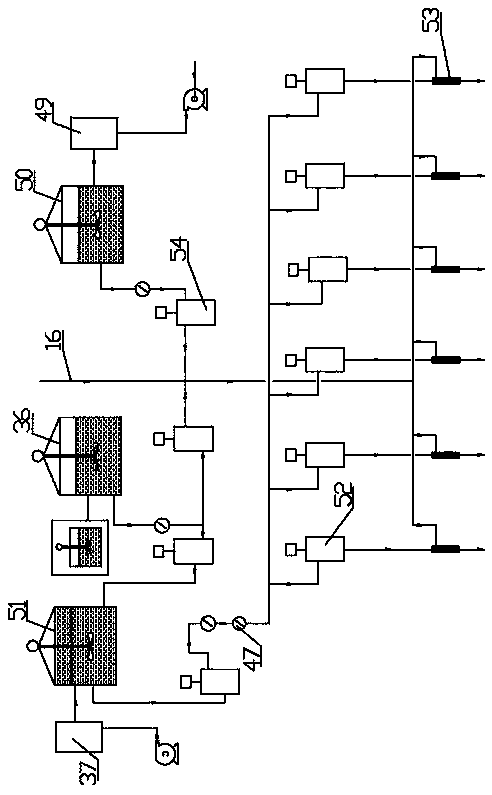

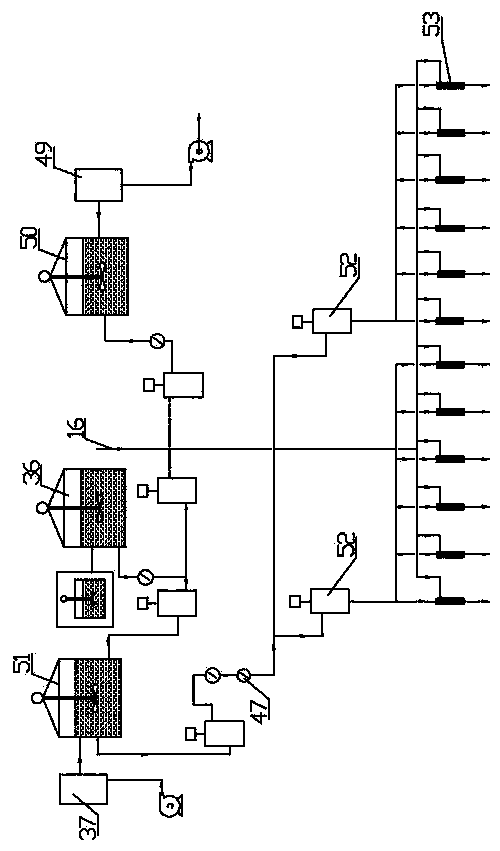

[0037] Example 1: as attached Figure 4 to the attached Figure 5 As shown, the single-pump and single-well two-level concentration deployment weak alkali ternary injection device includes AS storage tank 1, S storage tank 2, SP storage tank 3 and PLC controller, and the AS storage tank 1 is provided with an alkali mother liquor inlet 5 , the first surfactant mother liquor inlet 6 and the first water inlet 7, are provided with the second surfactant mother liquor inlet 8 and the second water inlet 9 on the S storage tank 2, and are provided with the polymer mother liquor on the SP storage tank 3 The inlet 10, the third surfactant mother liquor inlet 11 and the third water inlet 12; the SP mixed liquid main line 13 is fixedly installed at the liquid outlet of the SP storage tank 3, and the outlet end of the SP mixed liquid main line 13 is connected in series with The first booster pump 14 is fixedly connected with at least one SP mixed solution branch line 15 on the SP mixed so...

Embodiment 2

[0056] Example 2: as attached Figure 4 to the attached Figure 5 As shown, the using method of this single pump single well two-level concentration allocation weak base ternary injection device is carried out according to the following method: alkali mother liquor, surfactant mother liquor and water respectively pass through the corresponding alkali mother liquor inlet 5, the first surface The active agent mother liquor inlet 6 and the first water inlet 7 enter the AS storage tank 1 and mix evenly to obtain an AS mixed solution. The surfactant concentration in the AS mixed solution is the injection concentration of the surfactant, and the surfactant mother liquor and water pass through respectively. The corresponding second surfactant mother liquor inlet 8 and the second water inlet 9 enter into the S storage tank 2 and obtain the S solution after mixing uniformly, and the surfactant concentration in the S solution is the same as the surfactant concentration in the AS mixed s...

Embodiment 3

[0063] Example 3: As the optimization of Example 2, in order to further reduce the viscosity loss and concentration error of the ground purpose liquid, the first flow meter 27 sends the flow data to the PLC controller, and the PLC controller injects the requirements according to the injection well flow rate and the first flow rate. The flow rate data fed back by the meter 27 controls the opening of the first electric valve 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com