Gaskets for fuel cells

A fuel cell and gasket technology, which is applied in the field of fuel cell gaskets, and can solve problems such as excessive compression of the gasket body 21

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Hereinafter, embodiments of the present invention will be described based on the drawings.

no. 1 example

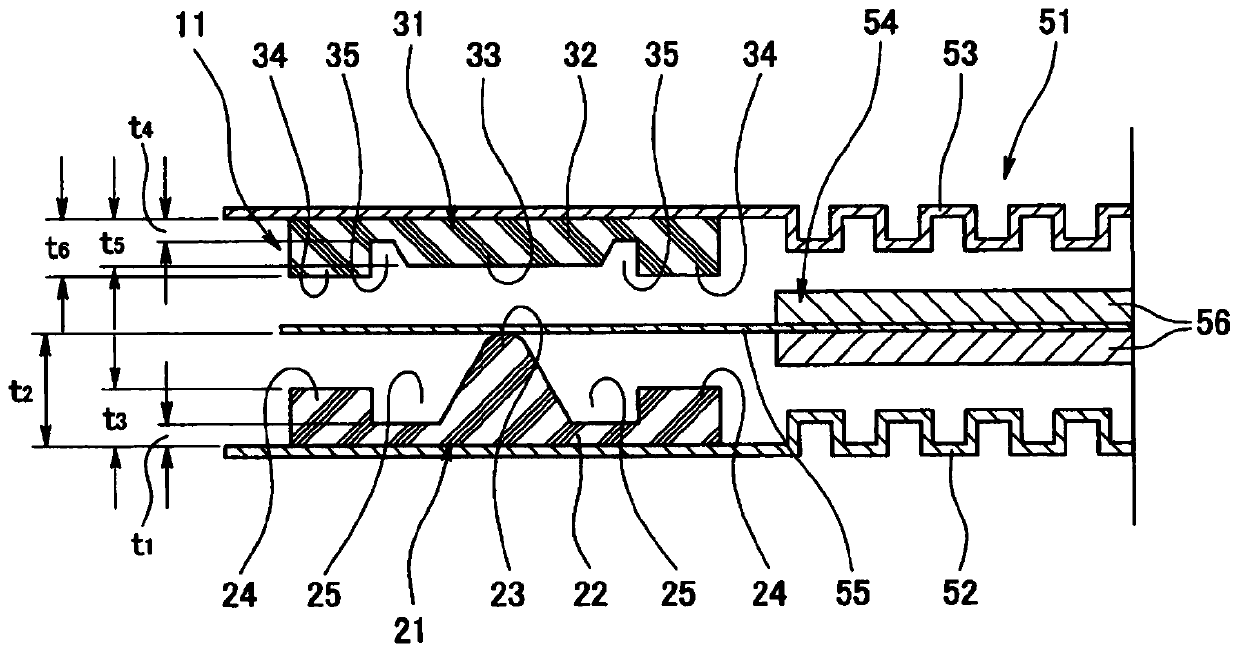

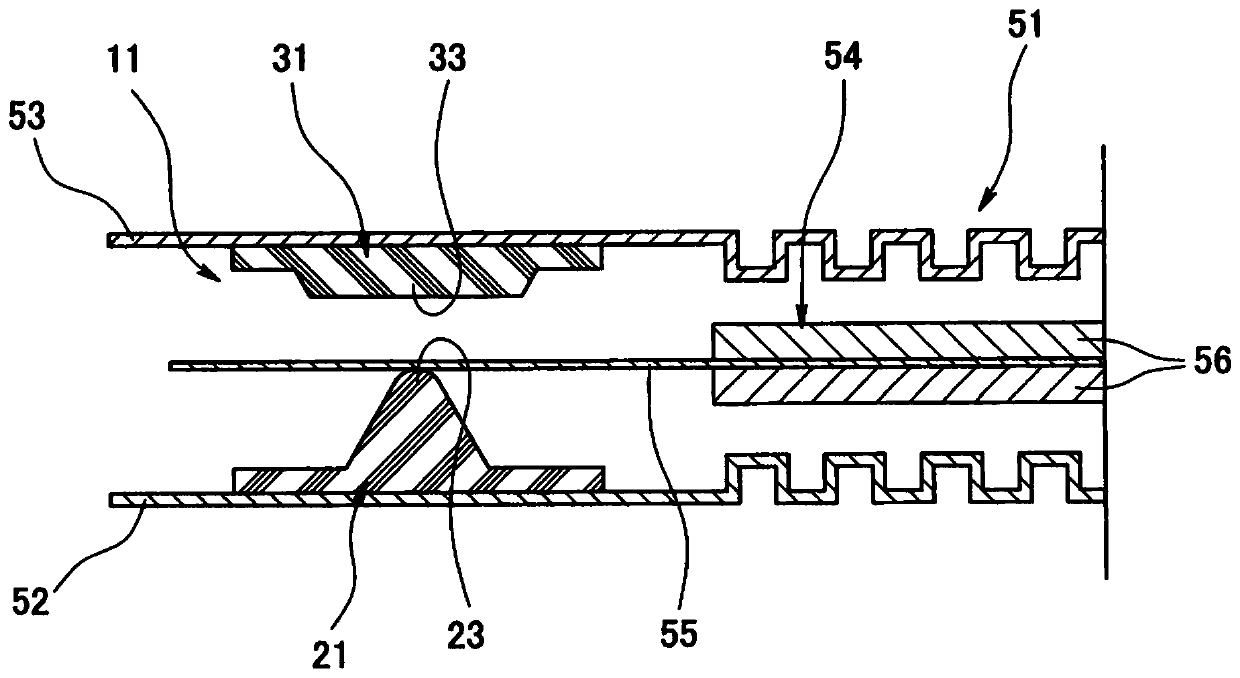

[0037] like figure 1 As shown, the fuel cell gasket 11 according to this embodiment includes an intermediate member 54 including an MEA (membrane electrode assembly) 55 and a GDL (gas diffusion layer) 56 mounted between a pair of separators 52 and 53 . A gasket for the fuel cell 51 having a structure including a gasket main body (first gasket main body) 21 held on one separator 52 of a pair of separators 52 and 53, and a gasket held on the other The spacer main body (second spacer main body) 31 on the separator 53 is in contact with the MEA 55 of the intermediate member 54 at positions where the two spacer main bodies 21 and 31 overlap on a plane, respectively. The pad main bodies 21 and 31 are each molded from a predetermined rubber-like elastic body or the like.

[0038] exist figure 1 The first pad main body 21 on the lower side includes a flat pad base 22 and a lip-shaped contact portion 23 with a mountain-shaped cross-section. Lip-shaped contact portion 23 . Further...

no. 2 example

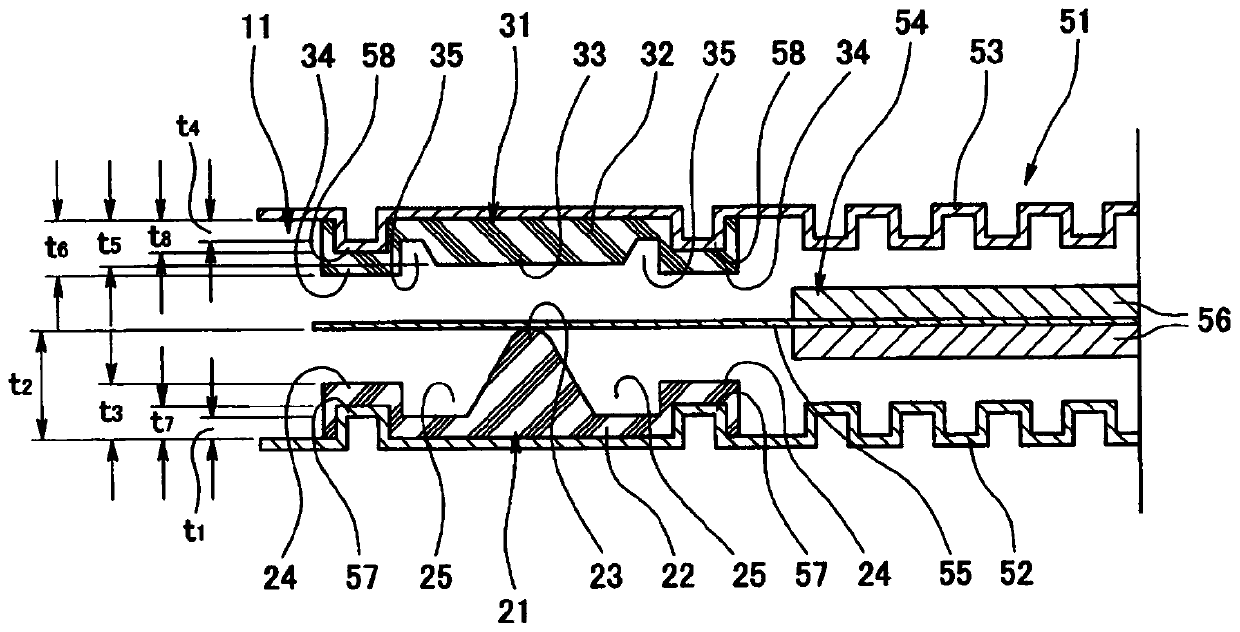

[0043] Next, in the fuel cell gasket 11 according to the second embodiment, in addition to the structure similar to that of the above-described first embodiment, the respective separators 52 and 53 are provided with convex portions 57 and 58, The protruding portions 57 and 58 support the respective standard dimension fixing embankment portions 24 and 34 . For example, the protrusions 57 and 58 are formed into a hollow three-dimensional shape by punching a part of the metal separators 52 and 53 , and all or a part (all in the figure) are embedded in the standard size fixing embankments 24 and 34 .

[0044] Accordingly, according to this configuration, the embankments 24 and 34 for fixing the standard size of a relatively soft material are supported by the convex parts 57 and 58 of a relatively hard material, so that the embankment parts 24 and 34 for fixing the standard size can be prevented from collapsing.

[0045] For the thickness (height) dimension t of the convex portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com