Automatic pick and place tool box system

An automatic pick-and-place and toolbox technology, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of unclear classification of scattered parts and tools, inconvenient search, poor management, etc., and achieve high integration rate, convenient search, and storage large space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

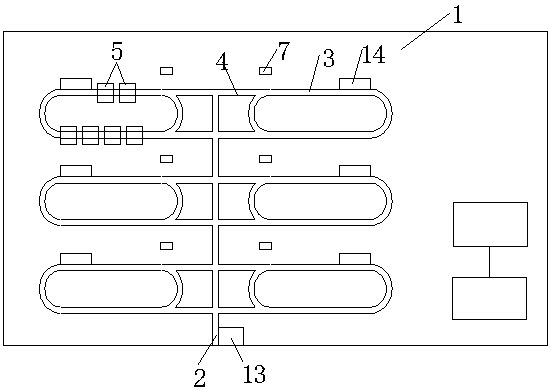

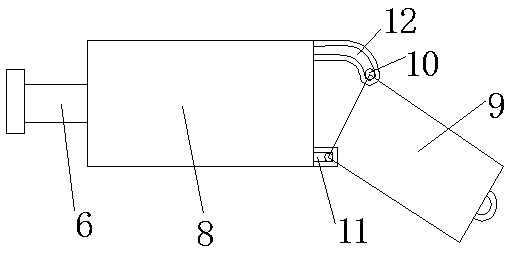

[0013] As shown in the figure, the automatic pick-and-place toolbox system of the present invention includes a main body case 1, and a plurality of guide rail groups are arranged on the rear side wall of the main body case 1, and each guide rail group includes a vertically arranged lifting guide rail 2 and The annular guide rails 3 arranged on both sides of the lifting guide rail 2, each annular guide rail 3 is provided with one or two guide rail passages 4 communicated with the lifting guide rail 2, and a plurality of tool boxes 5 are respectively arranged on each annular guide rail 3, so A guide block 6 is provided at the bottom of the tool box 5, and the guide block 6 is clamped on the ring guide rail 3, and a label is provided on each tool box 5, and an image acquisition device is provided at the junction of each ring guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com