Electric pencil peeling device

一种削笔器、电动的技术,应用在削尖装置、印刷、办公用品等方向,能够解决影响电动削笔机正常工作性能、电机处于通电状态、无法保证刨削性能等问题,达到提高连接稳定性差、保证正常刨削、提高稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

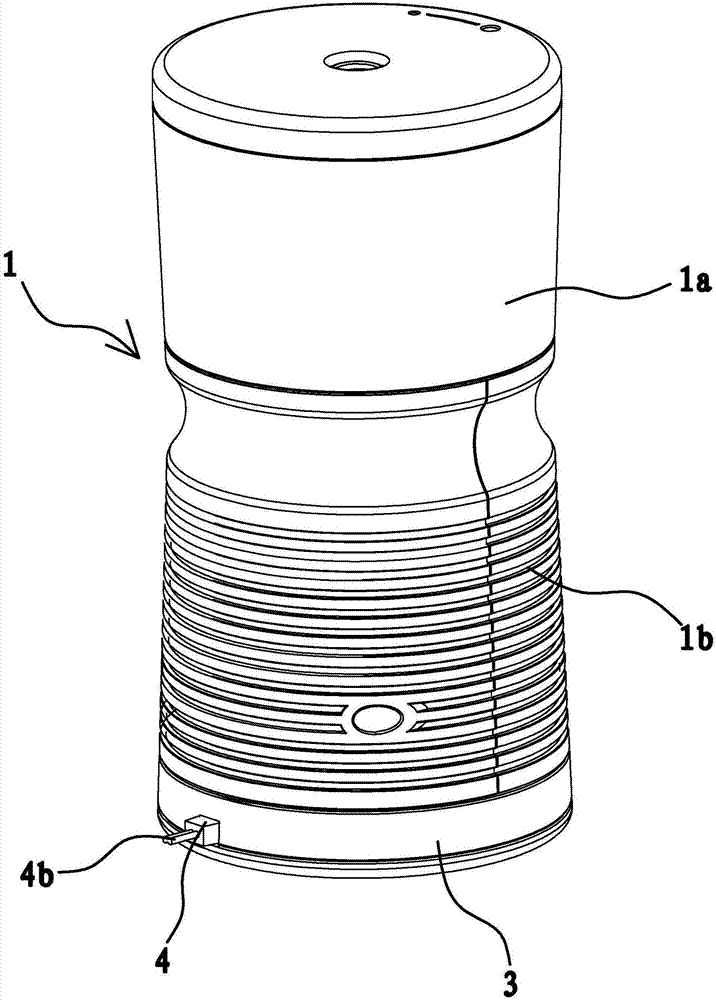

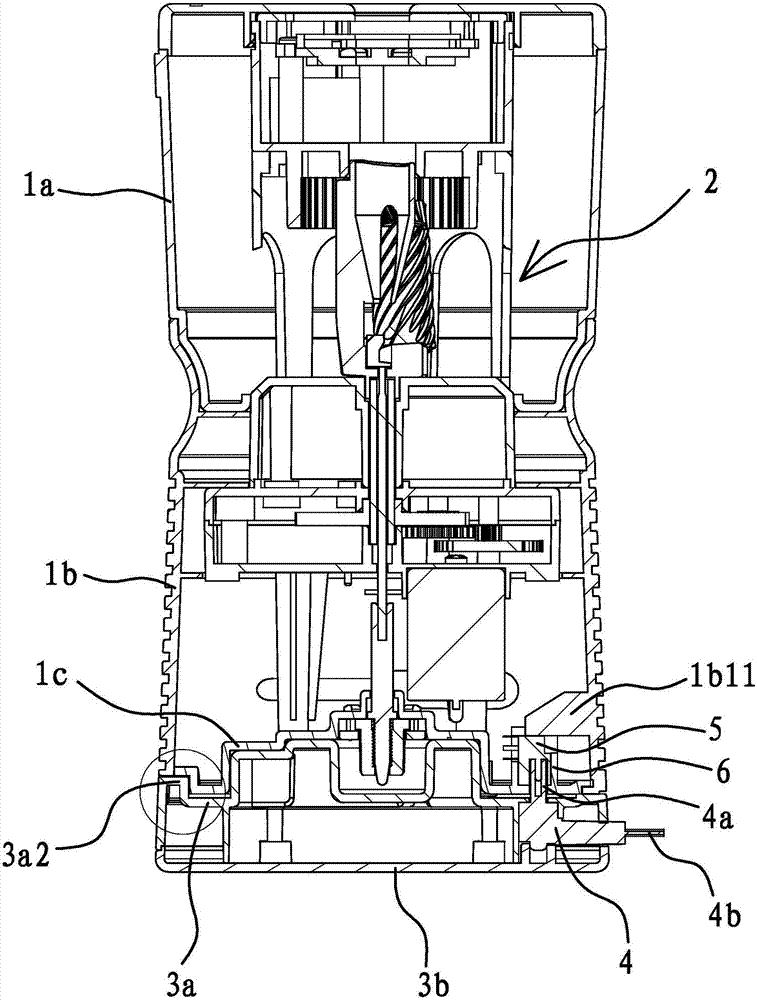

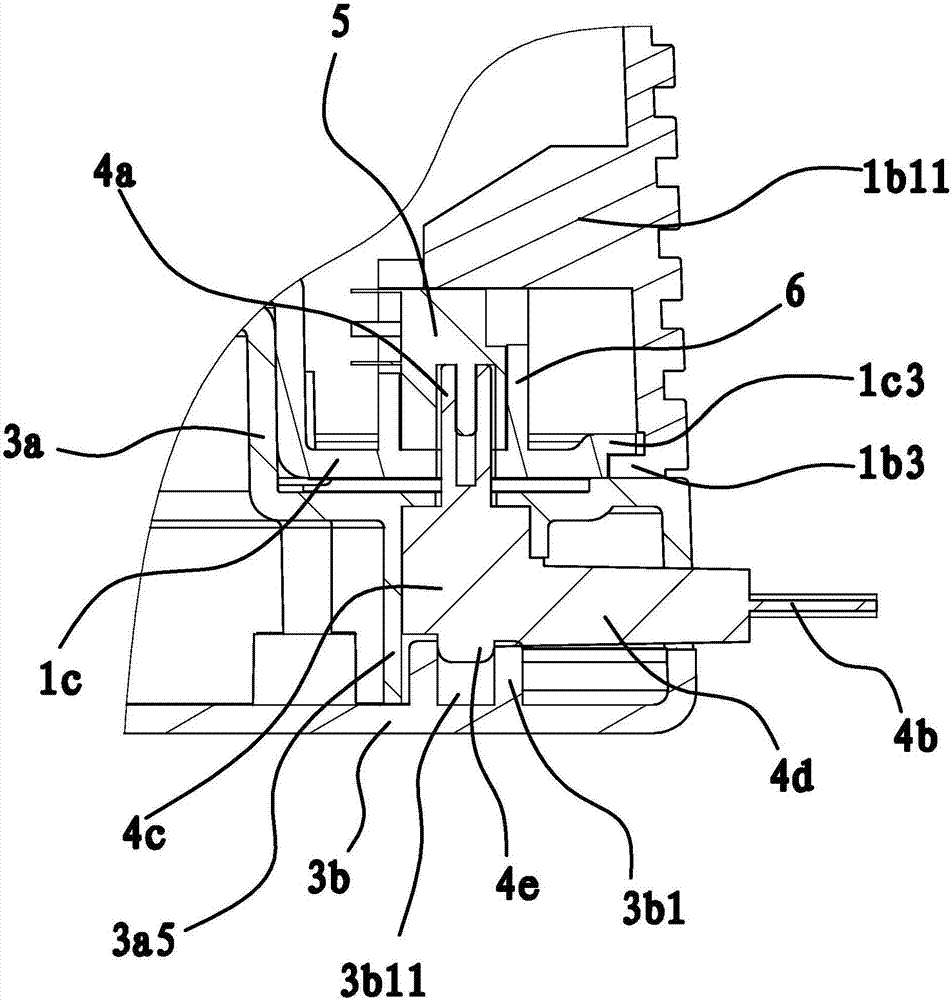

[0042] Such as figure 1 , figure 2 , Figure 5 , Figure 7 and Figure 8 As shown, an electric pencil sharpener includes a casing 1 and a pencil sharpening core 2 arranged in the casing 1. The casing 1 includes an upper casing 1a, a lower casing 1b, and a bottom cover 1c from top to bottom. , the lower end of the lower casing 1b is open, the bottom cover 1c is connected to the lower end of the lower casing 1b and closes the opening of the lower casing 1b, the upper part of the pencil sharpening movement 2 is located in the upper casing 1a, and the top of the pencil sharpening movement 2 The lower part is located in the lower housing 1b, and the lower end of the pencil sharpener movement 2 has several connecting posts, the pencil sharpener movement 2 and the bottom cover 1c are fixed by fasteners passing through the bottom cover 1c and penetrating into the connecting posts, and the pencil sharpener For the specific structure of the movement 2, reference may be made to the ...

Embodiment 2

[0053] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the positioning structure includes a connecting cavity arranged at the center of the bottom of the casing 1 and a raised matching part at the center of the upper end of the base 3 , the cross section of the fitting part is non-circular, the shape of the connecting cavity is the same as that of the fitting part and the fitting part is embedded in the connecting cavity.

[0054] Using a positioning structure formed by a non-circular mating portion and a connecting cavity with the same shape as the mating portion can also prevent the casing 1 from moving in the radial direction relative to the base 3 due to vibration, so as to improve the efficiency The problem of poor connection stability between the power connector 4 and the power connector 5 caused by automatic power-off during chip removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com