Wangeviry stope face roof hydraulic fracturing weakening method and device

A mining face and hydraulic fracturing technology, which is applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as low safety, threat to worker safety, and underground air pollution, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

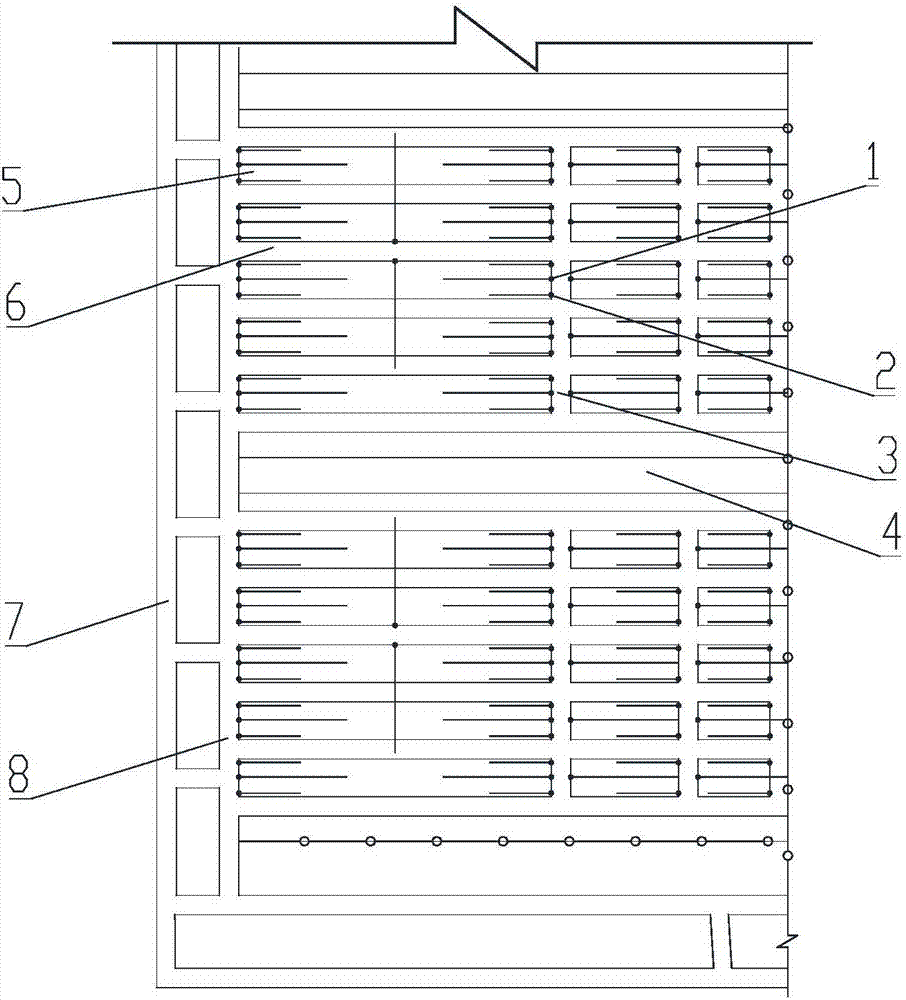

[0035] combine Figure 1 to Figure 3 As shown, in the method for weakening the roof hydraulic fracturing of the Wangerville working face provided by the embodiment of the present invention, the two ends of the mining working face are respectively provided with a joint roadway 3 and / or a transport roadway 8, and a coal pillar 5 is arranged Between two adjacent lanes 3 or between the transport lane 8 and the lane 3 adjacent to the transport lane 8, section branches are arranged between adjacent coal pillars 5. Lane 6 is also provided with transport flat lane 7 (as in the left side of transport flat lane 8 figure 1 shown), the method includes the following steps:

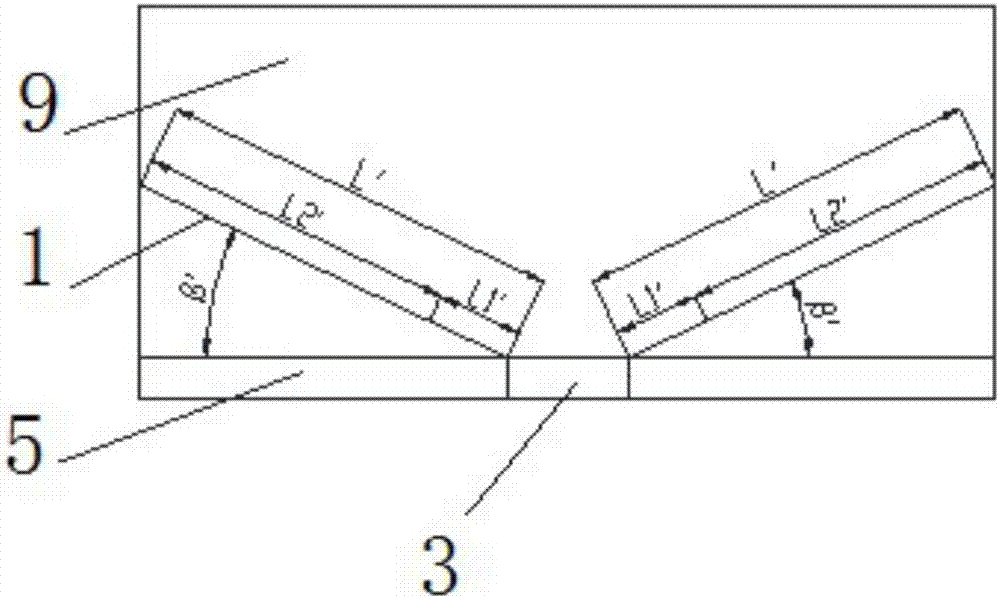

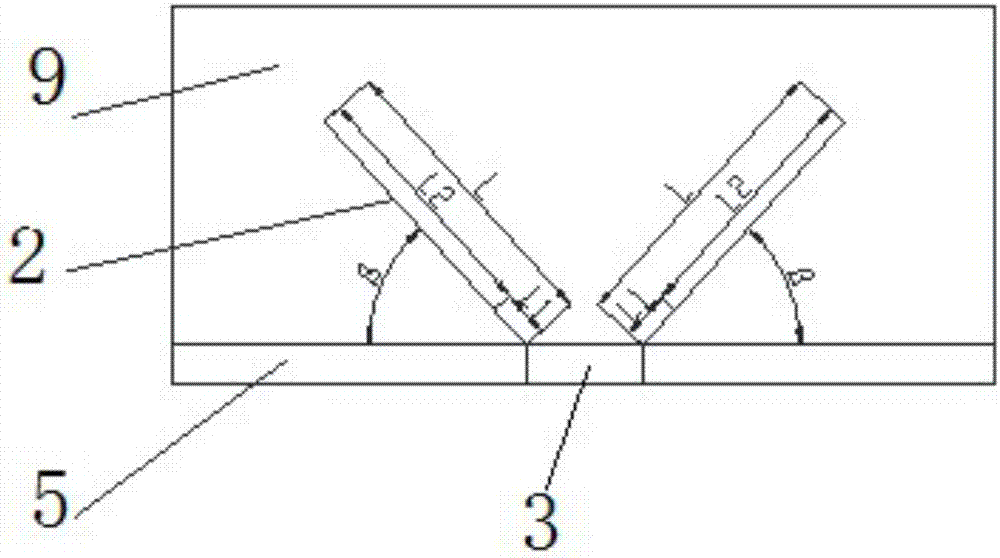

[0036] S1: Determine the structural parameters of the roof rock layer 9 and the coal pillar 5 of the mining face. Specifically, the structural parameters of the roof strata 9 are determined according to the columnar diagram of the borehole in the Wangerville mining face or peeped through the borehole. Among them, th...

Embodiment 2

[0050] The present invention also provides a hydraulic fracturing weakening device for the roof of Wangerville mining face, the device includes:

[0051] The parameter acquisition unit is used to determine the structural parameters of the roof rock layer 9 and the coal pillar 5 of the mining face;

[0052] The calculation unit is used to calculate the basic parameters of hydraulic fracturing drilling according to the structural parameters of the roof rock layer 9 and the coal pillar 5;

[0053] The drilling unit is used to drill a hydraulic fracturing hole obliquely to the roof rock layer 9 above the coal pillar 5 from the transport roadway or joint roadway according to the calculation result of the calculation unit;

[0054] The hydraulic fracturing weakening treatment unit is used for performing hydraulic fracturing weakening treatment at a preset position on a hydraulic fracturing borehole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com