A kind of dense steel wire rope cover retraction method in coal mining face

A technology of coal mining face and steel wire rope, which is applied in ground mining, mining equipment, earth-moving drilling, etc., can solve the problems of changing the stress state of adjacent supports, affecting the retraction efficiency of the working face, and threatening the life safety of workers, etc. The effect of ensuring smooth retraction, avoiding the reduction of the mining space section, and improving the retraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

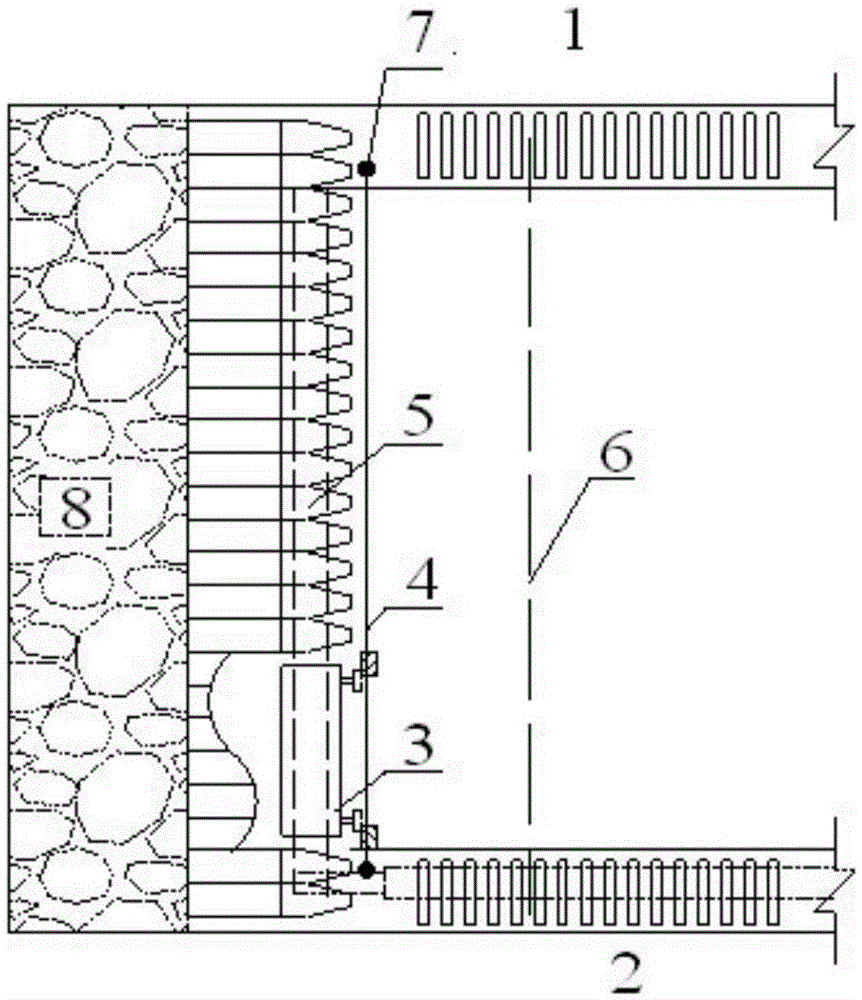

[0023] Such as figure 1 As shown, the coal mining face intensive steel wire rope shield retreat method of the present invention, concrete steps are as follows:

[0024] Step 1: When the working face advances to a place 10m away from the stop mining line 6, the shearer 3 cuts from the nose to the tail and then stops, and only cuts the roof;

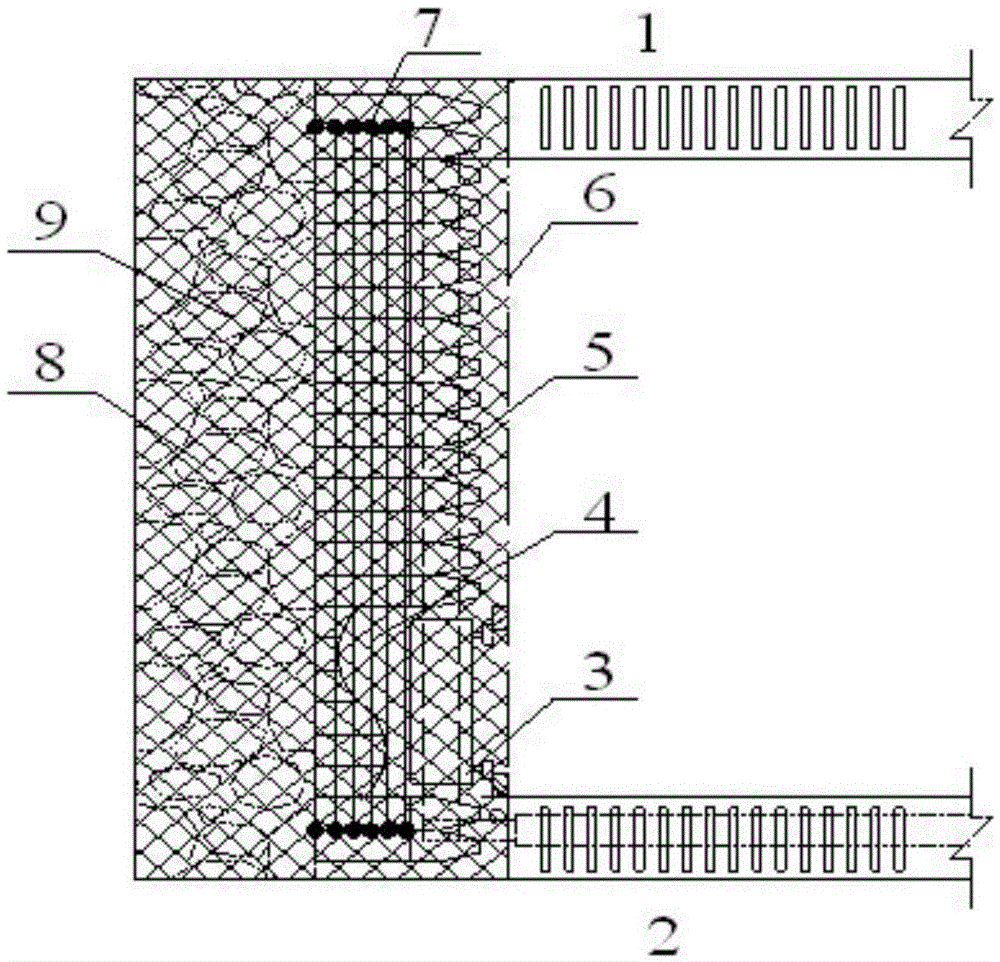

[0025] Step 2: After confirming that there are no potential safety hazards, the laying process of steel wire rope 4 and plastic steel mesh 9 is carried out: pre-drilling anchor rod 7 in track entryway 1 and transportation entryway 2, and between the hydraulic support 5 top beam and the coal seam roof. After the plastic steel mesh 9 is laid, the steel wire rope 4 is put into it, and it is laid frame by frame from top to bottom. on the anchor rod 7 provided; the steel wire rope 4 adopts underground waste steel wire rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com