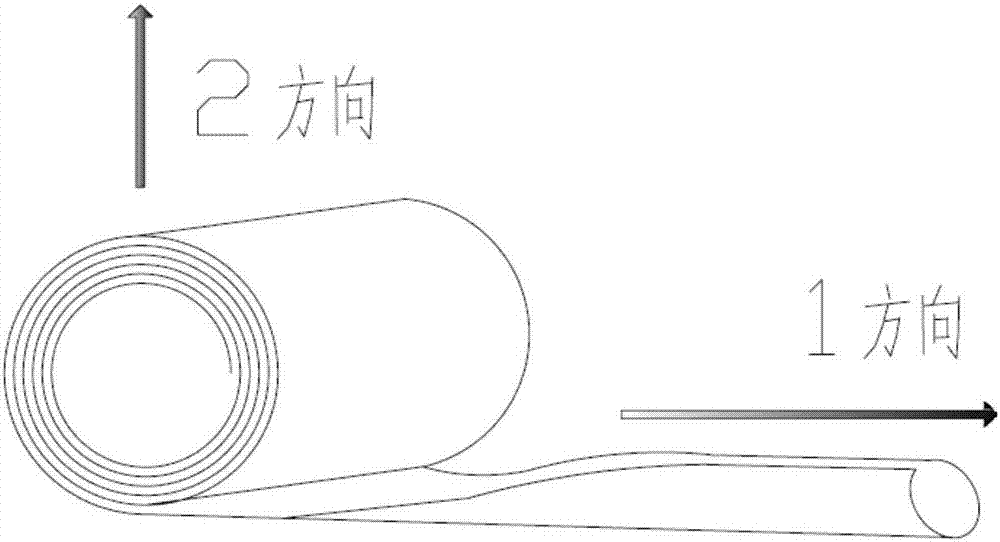

Bistable shell structure and manufacturing method thereof

A manufacturing method and bistable technology, which can be applied in the direction of slender elements, building elements, etc., can solve the problems of inability to improve the rigidity of the side bistable structure, increase the weight of the structure, and damage the shell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

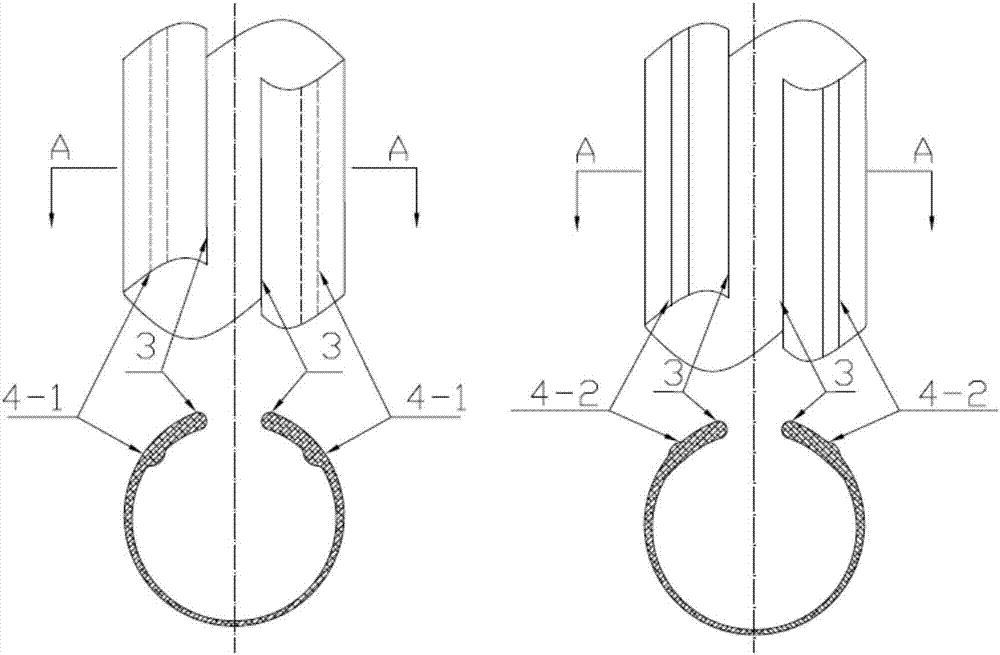

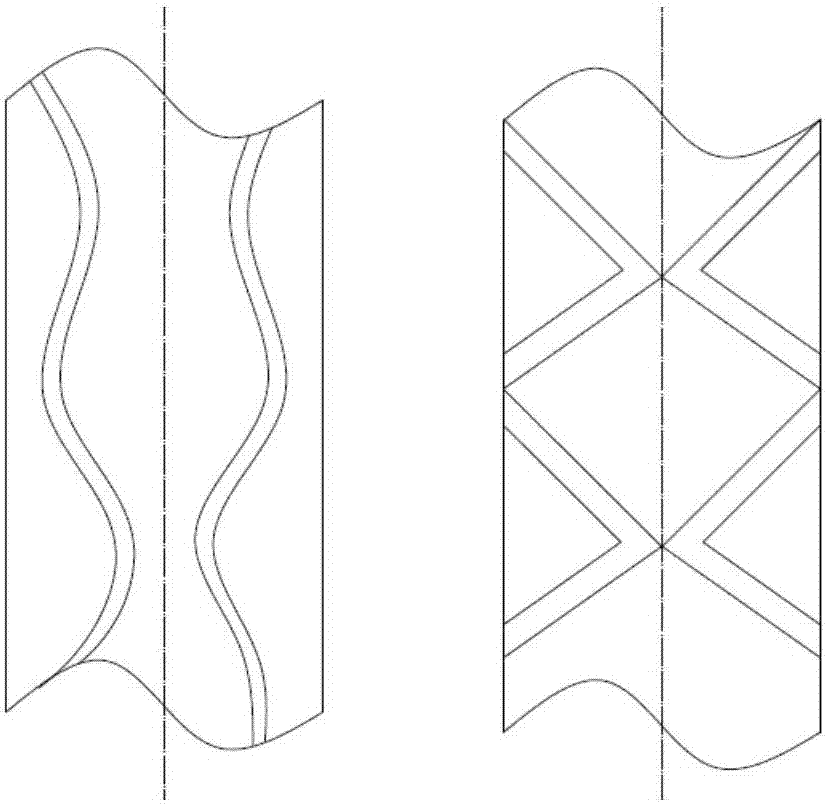

[0068] Embodiment 1: Forming of the Rib Structure Taking molding as an example, a mold with a rib structure is processed. Using fiber prepreg as raw material, first cut the prepreg according to the designed size, then lay the outer layer into the mold, lay the material used for the rib along the rib structure, and then lay other materials layer by layer in the mold , and after the mold is molded according to the required temperature and pressure of the material.

Embodiment 2

[0069] Embodiment 2: Forming of the rib structure Taking pultrusion as an example, firstly, the cross-section in the direction of state 1 is used as the size to process the extrusion die head, which is mainly prepared by pultrusion equipment. If prepreg is used, under the action of external traction, the prepreg is preheated, sent into the mold cavity for heating and forming, and then cooled and shaped to form a finished product. If it is a dry yarn, it needs to be dipped in the preheating stage, and then shaped. The feature of this implementation method is that the 3 parts at the edge of the opening need to be thickened so that the shape can be fixed during the material forming process, and the thickened part can be regarded as a rib structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com