Translation transfer device for alternate traction of support cylindrical parts

A cylindrical, support-type technology, applied in transportation and packaging, conveyors, metal processing, etc., can solve the problems of high labor intensity, high precision requirements for guide rail docking, and low safety, so as to improve safety and reduce manual participation degree, the effect of smooth movement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

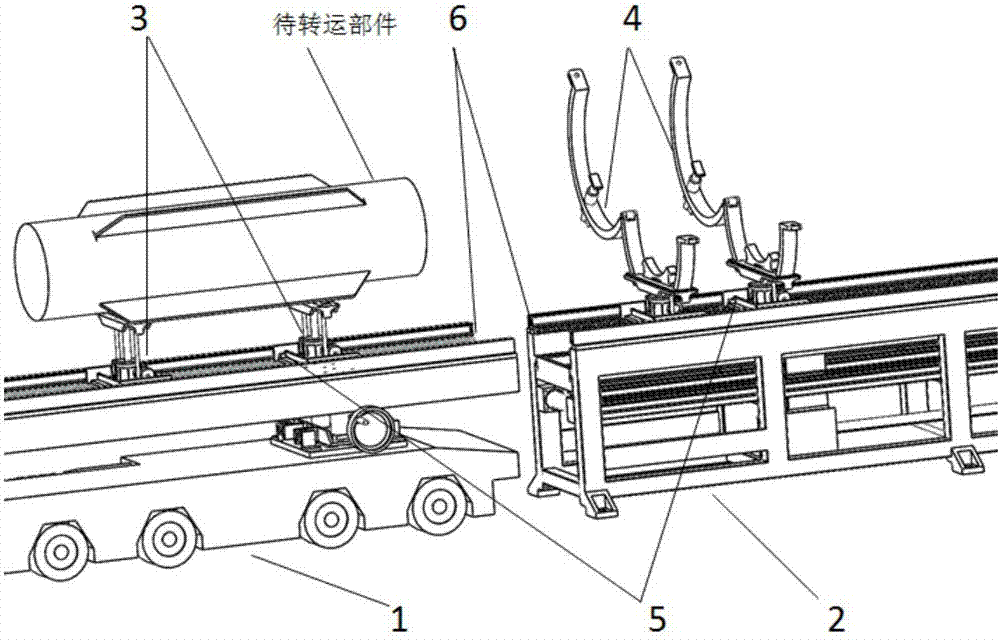

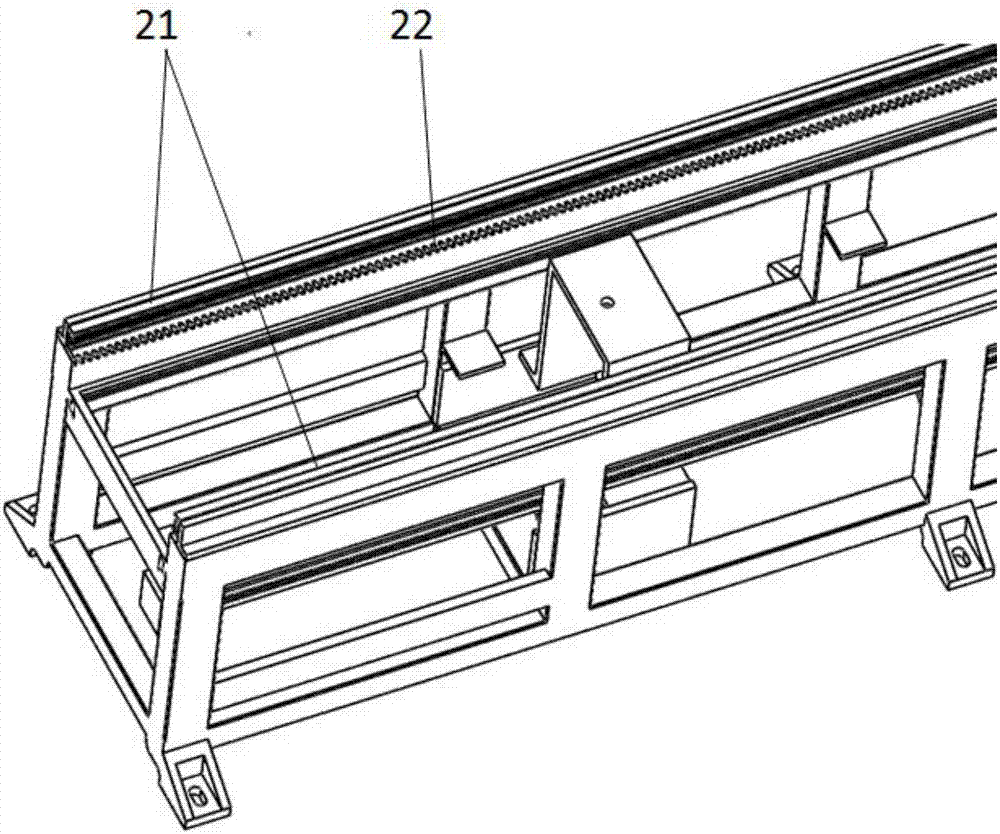

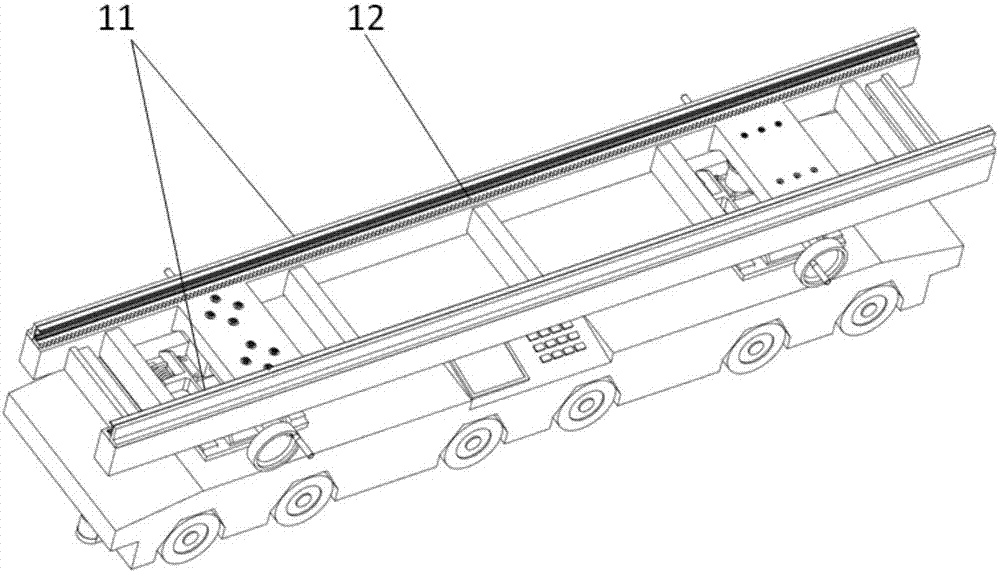

[0033] see figure 1, an alternate traction support type translational turnover device for cylindrical parts, including a moving base 1, a static base 2, a support frame 3 and a transfer frame 4; there are two support frames 3, which are installed on the body of the moving base 1 in the same direction On the two first linear guide rails 11 arranged in parallel, there are two transfer racks 4, which are installed in the same direction on the two second linear guide rails 12 arranged in parallel on the base of the static base 2, wherein, in the same direction The inboard of any support frame 3 installed and the inboard of any transfer frame 4 installed in the same direction are respectively provided with a distance sensor 5, which is used to detect the distance between two support frames 3 and two transfer frames 4, and the moving base Each of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com