Precise positioning system for coke-oven locomotive

A precise positioning and precise positioning technology is applied in the field of precise positioning systems for coke oven locomotives, which can solve problems such as poor positioning accuracy of coke oven locomotives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

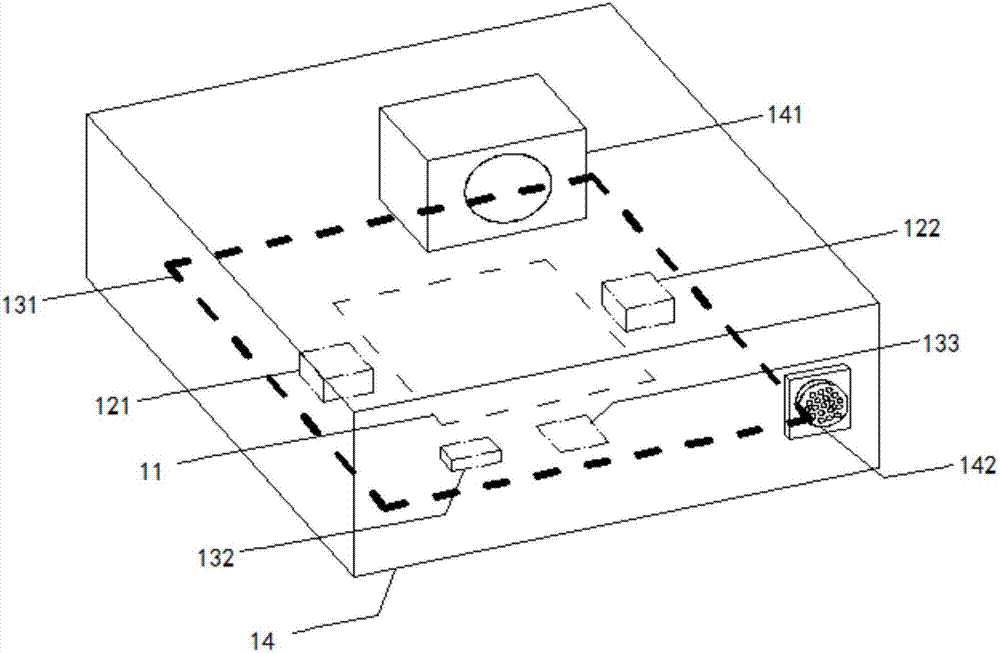

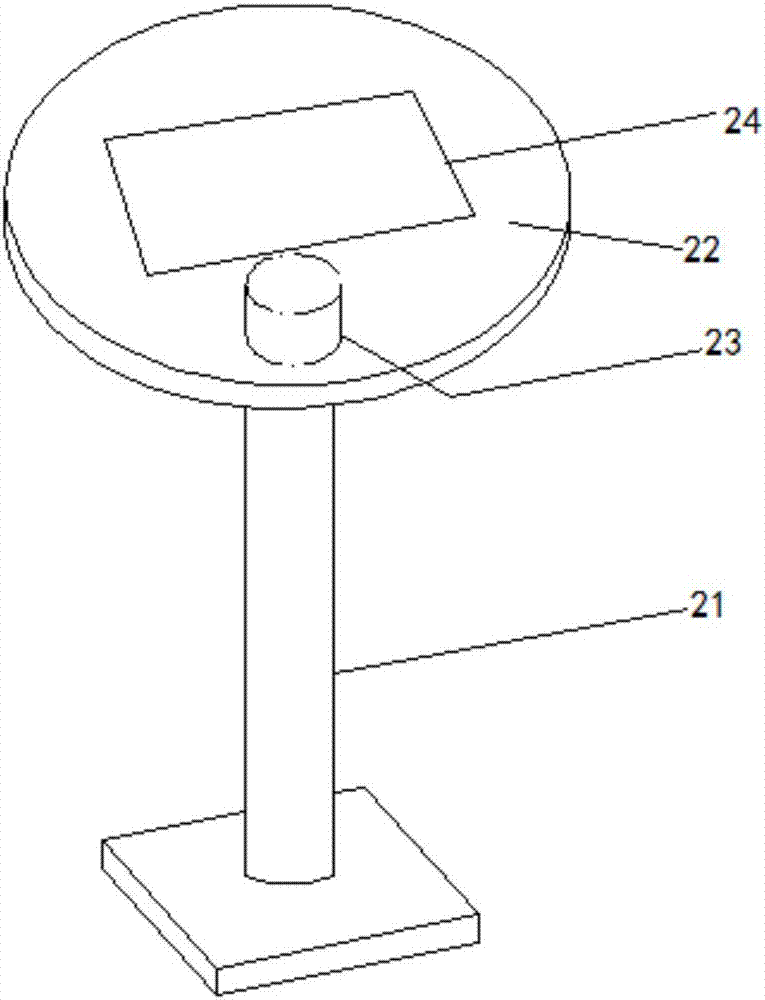

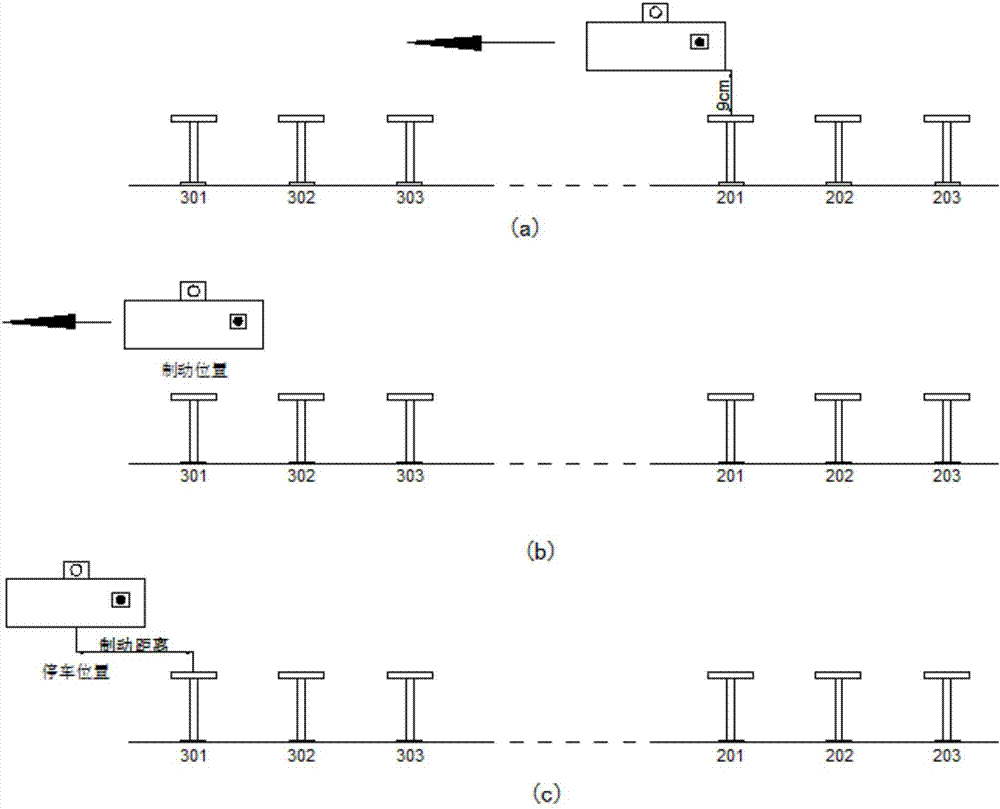

[0028] This example provides a precise positioning system for a coke oven locomotive, including a first positioning device 1, a second positioning device 2 and a PLC controller. The structural diagram of the first positioning device 1 is as follows figure 1 As shown, the structural diagram of the second positioning device 2 is as figure 2 As shown, through the induction of the first positioning device 1 and the second positioning device 2, and the cooperation with the PLC controller, the running speed and running state of the coke oven locomotive are adjusted to achieve the purpose of precise positioning.

[0029] Specifically, the first positioning device 1 includes: an RFID coarse adjustment module 11, a Hall effect fine positioning module 12, a control module 13 and a housing 14; The module 13 is connected with signals, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap