High-pressure water flushing rake head

A high-pressure, flushing technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of unreachable effect, water pressure damage, low water pressure, etc., and achieve the purpose of making up for the loss of water pressure and improving the impact effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

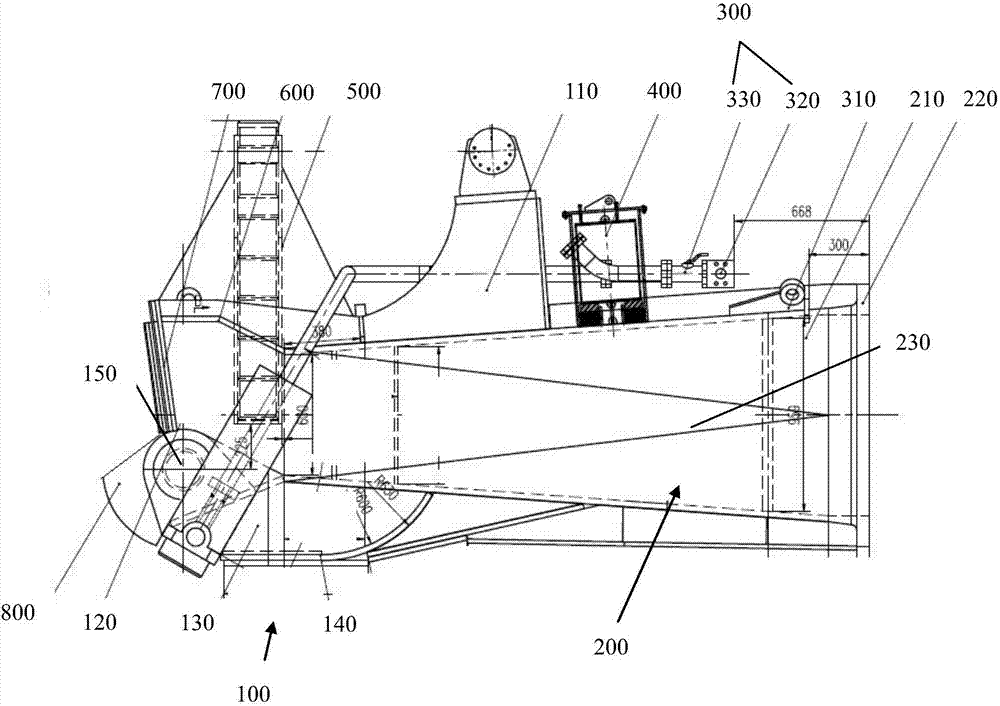

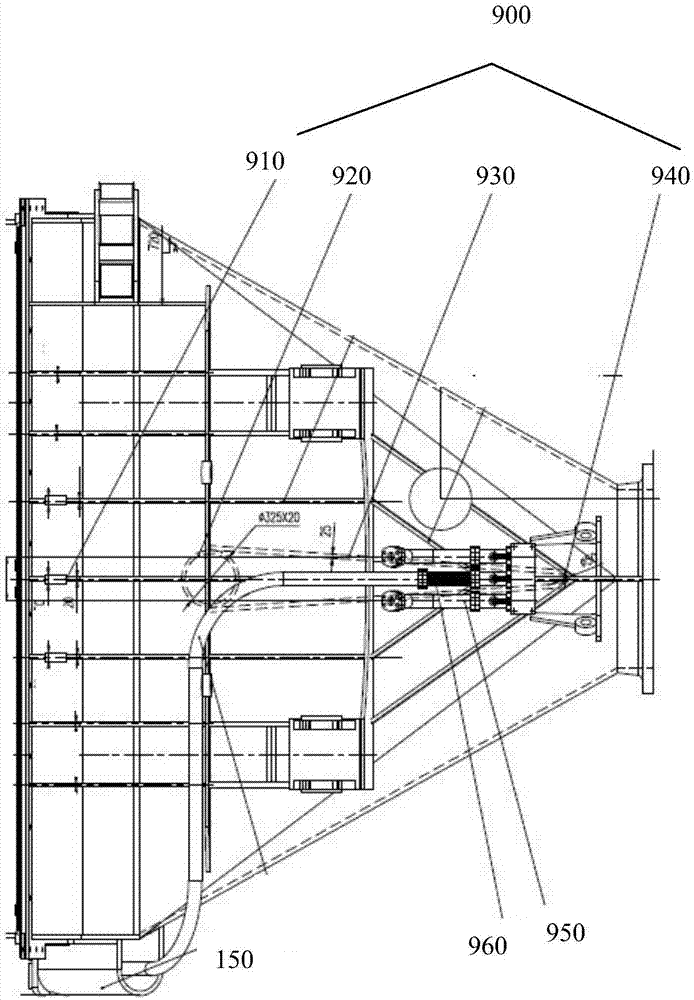

[0022] figure 1 It is a structural diagram of the present invention. figure 2 A diagram of the pipeline structure.

[0023] Such as figure 1 As shown, the high-pressure flushing rake head includes: a fixed body 100, a cylindrical structure 200, a high-pressure fitting 300, a positioning barrel 400, a handle 500, a flange 600, a sealing device 700, a crescent plate 800, and a pipe structure 900, and the cylinder The structure 200 is connected to the front end of the fixed body 100, the high-voltage fitting 300 is connected to the positioning barrel 400, the positioning barrel 400 is connected to the cylindrical structure 200, the lever 500 is connected to the upper end of the fixed body 100, and the flange plate 600 is set on the fixed body 100 At the joint with the cylindrical structure 200, the sealing device 700 is connected to the end of the fixed body 100, the crescent plate 800 is connected to the lower end of the fixed body 100, and the pipeline structure 900 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com