Construction method of whole stone-reinforced concrete combined stone imitating beam

A reinforced concrete and construction method technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems affecting the external appearance, achieve convenient construction, reduce the workload of cleaning and repairing, and increase the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the whole stone-reinforced concrete composite imitation stone structure is a whole stone-reinforced concrete composite imitation stone column.

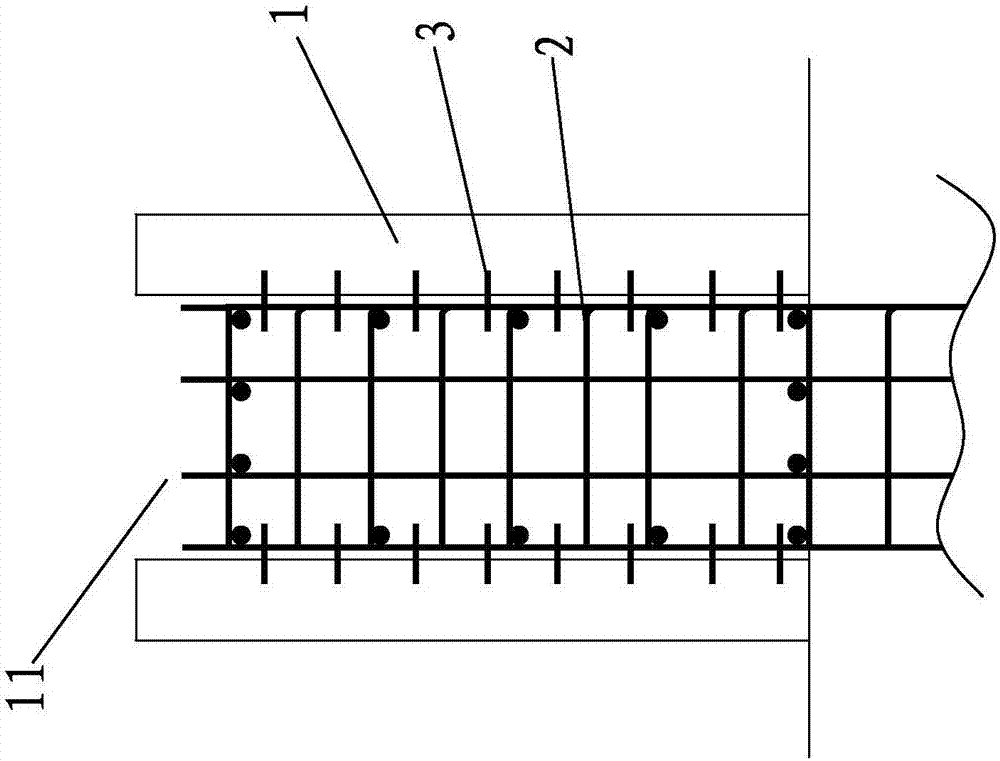

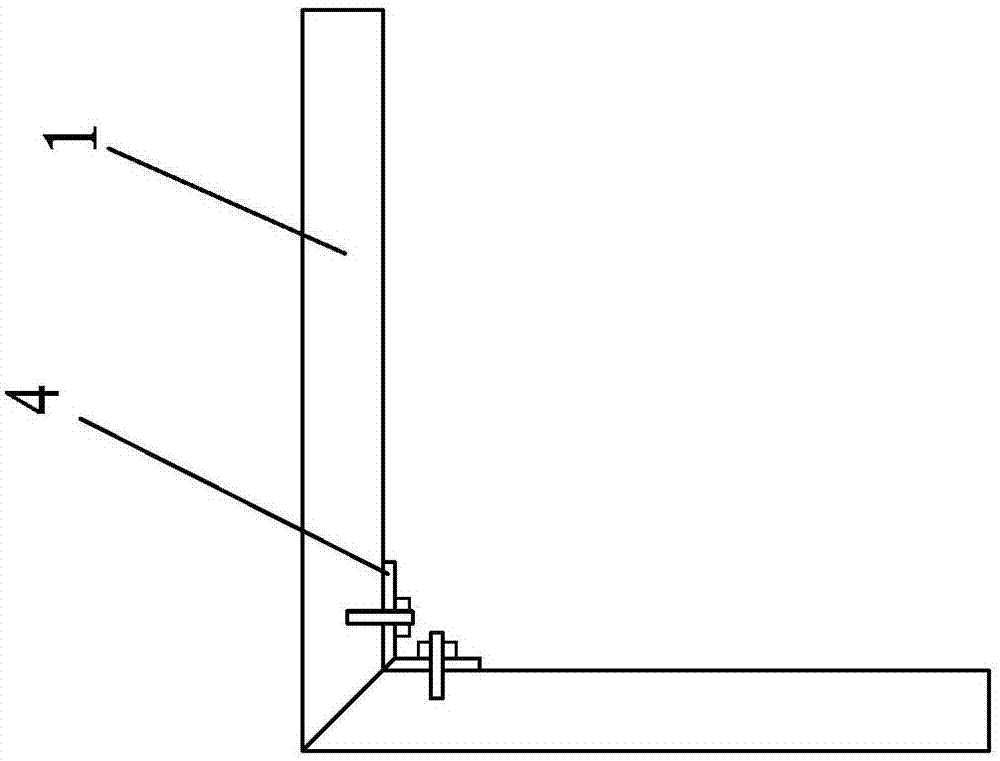

[0040] Such as Figure 1-2 As shown, this embodiment takes four whole stones 1 and the base to synthesize imitation stone pillars as an example. The four whole stones 1 are respectively fixed and placed on the base in a conventional manner, and each whole stone 1 is spliced with each other to form a hollow column. The lower part of the first reinforcement mesh 2 is respectively fixed on the construction position of the base in a conventional manner.

[0041] Specifically, the construction positions of the four whole stones 1 and the base form a column with a hollow structure and an upper opening 11, and each first steel mesh 2 is located in the hollow structure. Moreover, the transverse sections of two adjacent whole stones 1 are L-shaped, and they are fixedly connected together by a plurality of L-shaped...

Embodiment 2

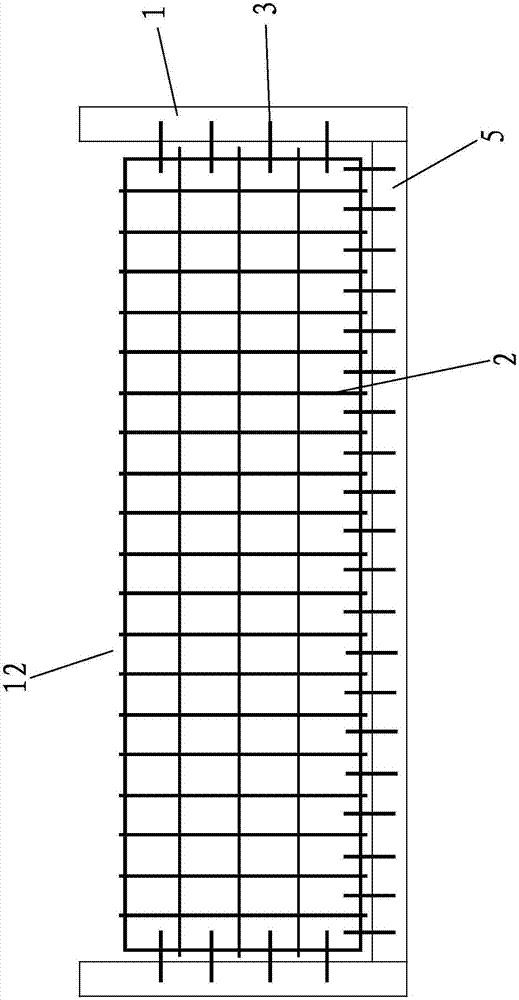

[0065] In this embodiment, the whole stone-reinforced concrete composite imitation stone structure is a whole stone-reinforced concrete composite imitation stone beam.

[0066] Such as Figure 2-3 As shown, taking four whole stones 1 and the beam bottom plate 5 to form an imitation stone beam as an example, each whole stone 1 is fixedly installed on the beam bottom plate 5 in a conventional manner, and each whole stone 1 is spliced with each other to form a hollow beam shape. , the first steel mesh 2 is arranged along the length direction of the beam and placed on the beam bottom plate 5 . Wherein, the beam floor 5 is installed on the construction site in a conventional manner in a direction parallel to the ground.

[0067] In this embodiment, the beam bottom plate 5 is also a whole stone.

[0068] Specifically, the four whole stones 1 and the beam bottom plate 5 form a cross beam with a hollow structure and an upper opening 12, the first steel mesh 2 is located in the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com