Bridge maintenance equipment

A technology for maintaining equipment and bridges. It is applied in the direction of preventing contact with live contacts, electrical components, coupling devices, etc. It can solve problems such as easy loosening, electric shock to users, and poor plugging stability, so as to improve work efficiency and safety. , prevent the exposure of the power-in connection, and the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

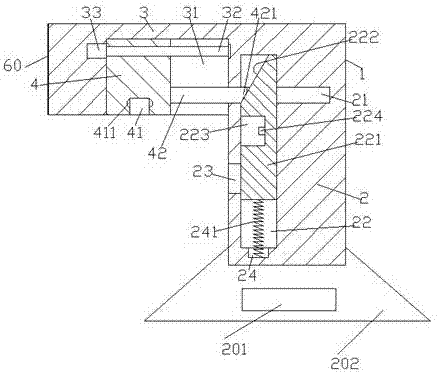

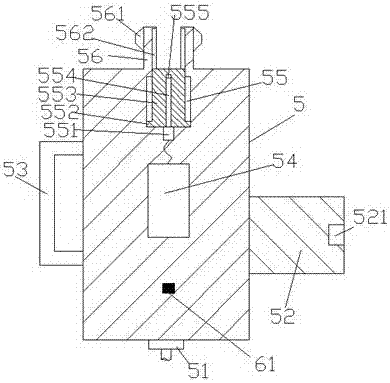

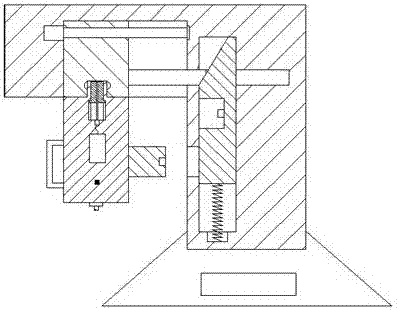

[0023] Such as Figure 1-Figure 6 As shown, a bridge maintenance device of the present invention includes a power feed frame 1 and a power feed column 5 composed of an attachment part 3 and a power feed end 2, and the attachment part 3 is fixedly arranged at the power feed end In the upper position on the left side of the part 2, a push-out chute 31 is provided in the bottom end surface of the attachment part 3, and a first screw 32 is provided in the push-out chute 31, and the first screw 32 is left and right. The side end is connected with the first power device 33, and the right side end of the first screw rod 32 is connected with the inner end of the right side of the pushing chute 31 in rotation and fit connection, and the first screw rod 32 is provided with a joint pushing pusher for matching connection. Block 4, the right side end surface of the combined pushing block 4 under the first screw rod 32 is provided with a pushing rod 42 extended to the right, and the tail ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com