Deep drying box used for rolling mill

A drying box and depth technology, applied in the field of drying boxes, can solve the problems of easy rebound of pole pieces, failure to meet standard requirements, quality impact, etc., and achieve the effect of reducing pole piece rebound and improving battery quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

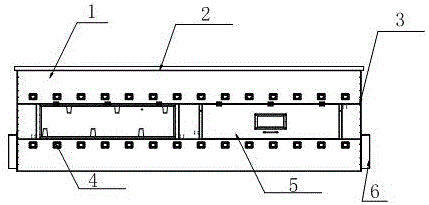

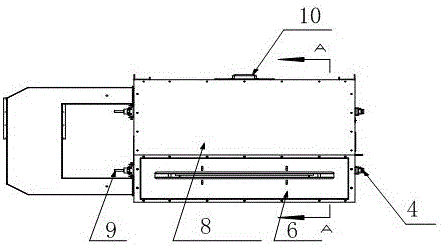

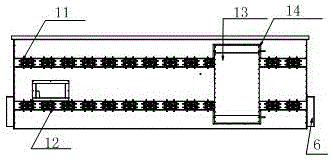

[0014] Such as Figure 1 to Figure 4 As shown, the deep drying box for the rolling mill of the present invention includes an outer wall 1, a bearing on the box body as a fixing plate 2, a frame 3 on both sides of the drying box, a roller channel steel fixing frame 4, a box door panel 5 of the drying box, a negative pressure chamber 6, Sealing plates at both ends of the drying box 8, box guide roller 9, explosion-proof opening 10, upper roller regulator 11, lower roller regulator 12, drying box air inlet elbow 13, drying box air inlet connection frame 14, inner wall 20 , upper air box 21, upper air chamber 22, upper air chamber adjustment support rod 23, driven roller 24, driving roller 25, lower air chamber adjustment support rod 26, lower air chamber 27, lower air chamber 28, belt trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com