Large power lead-acid storage battery pole group manufacturing method and lead-acid storage battery pole group

A technology of lead-acid battery and manufacturing method, which is applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc. It can solve the problems of low degree of automation, large size of pole group, poor consistency of pole group welding quality, etc., and achieve improvement The effect of battery quality, meeting environmental protection requirements, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

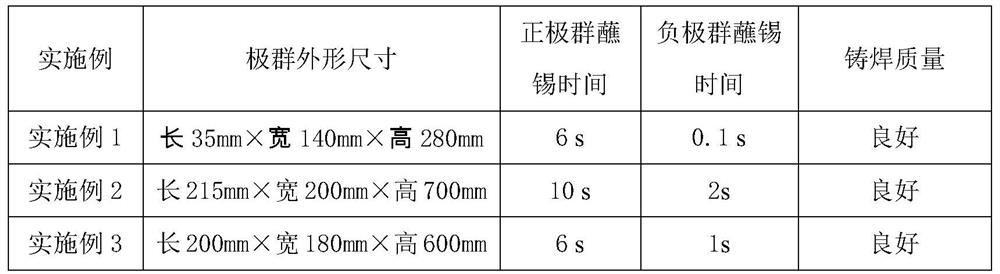

Embodiment 1

[0050] Manufactured in a small pole group, the size of the pole group is 35mm long x 140mm wide x 280mm high. .

[0051](a) Remove the additional process lugs of the negative (side) plate, brush the plate lugs, and clean the frame of the negative (side) plate in a stack.

[0052] (b) Single-piece positive, negative and side negative plates enter the lug cutting area, and the lug cutting is automatically completed. The roller brush device automatically polishes the upper and lower surface positions of the positive, negative and side negative plate lugs, and rolls Brush, the positive, negative and edge negative plates that have been cut and polished by the lugs enter the automatic encapsulation and grouping area respectively.

[0053] (c) The PE separator is automatically fed in, and the separator is automatically made into a sleeve shape by the lamination device, and the positive plate is sent into the separator sleeve by the pushing device. After the packaging is completed, t...

Embodiment 2

[0060] Large pole group manufacturing, pole group size: length 215mm×width 200mm×height 700mm, the size of the plate forming the pole group is 620mm in length, 190mm in width, and 10mm in thickness; (side) negative plate is 620mm in length, 190mm in width, and 4.5 in thickness mm.

[0061] (a) Remove the additional process lugs of the negative (side) plate, brush the plate lugs, and clean the frame of the negative (side) plate in a stack.

[0062] (b) Single-piece positive, negative and side negative plates enter the lug cutting area, and the lug cutting is automatically completed. The roller brush device automatically polishes the upper and lower surface positions of the positive, negative and side negative plate lugs, and rolls Brush, the positive, negative and edge negative plates that have been cut and polished by the lugs enter the automatic encapsulation and grouping area respectively.

[0063] (c) The PE separator is automatically fed in, and the separator is automatic...

Embodiment 3

[0070] Large pole group manufacturing, pole group size: length 200mm×width 180mm×height 600mm, the size of the plate forming the pole group is 500mm in length, 180mm in width, and 9mm in thickness; (side) negative plate length is 500mm, width 180mm, and thickness 3.5mm mm.

[0071] (a) Remove the additional process lugs of the negative (side) plate, brush the plate lugs, and clean the frame of the negative (side) plate in a stack.

[0072] (b) Single-piece positive, negative and side negative plates enter the lug cutting area, and the lug cutting is automatically completed. The roller brush device automatically polishes the upper and lower surface positions of the positive, negative and side negative plate lugs, and rolls Brush, the positive, negative and edge negative plates that have been cut and polished by the lugs enter the automatic encapsulation and grouping area respectively.

[0073] (c) The PE separator is automatically fed in, and the separator is automatically mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com