Triangular roller mechanism and winding device for separating directions of pole piece and diaphragm of lithium battery

A lithium battery and triangular roller technology, which is applied in secondary batteries, coiled strips, circuits, etc., can solve the problems of verticality and levelness operation difficulties, cumbersome operation of replacing worn rollers, etc., and achieves compact structure, convenience and speed Effect of changing rolls and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

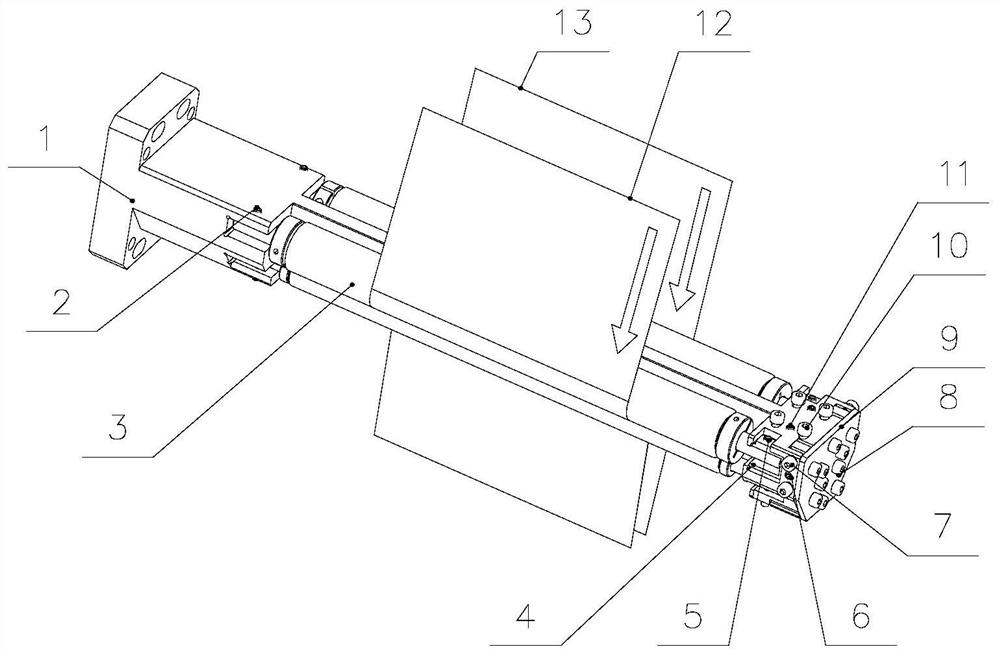

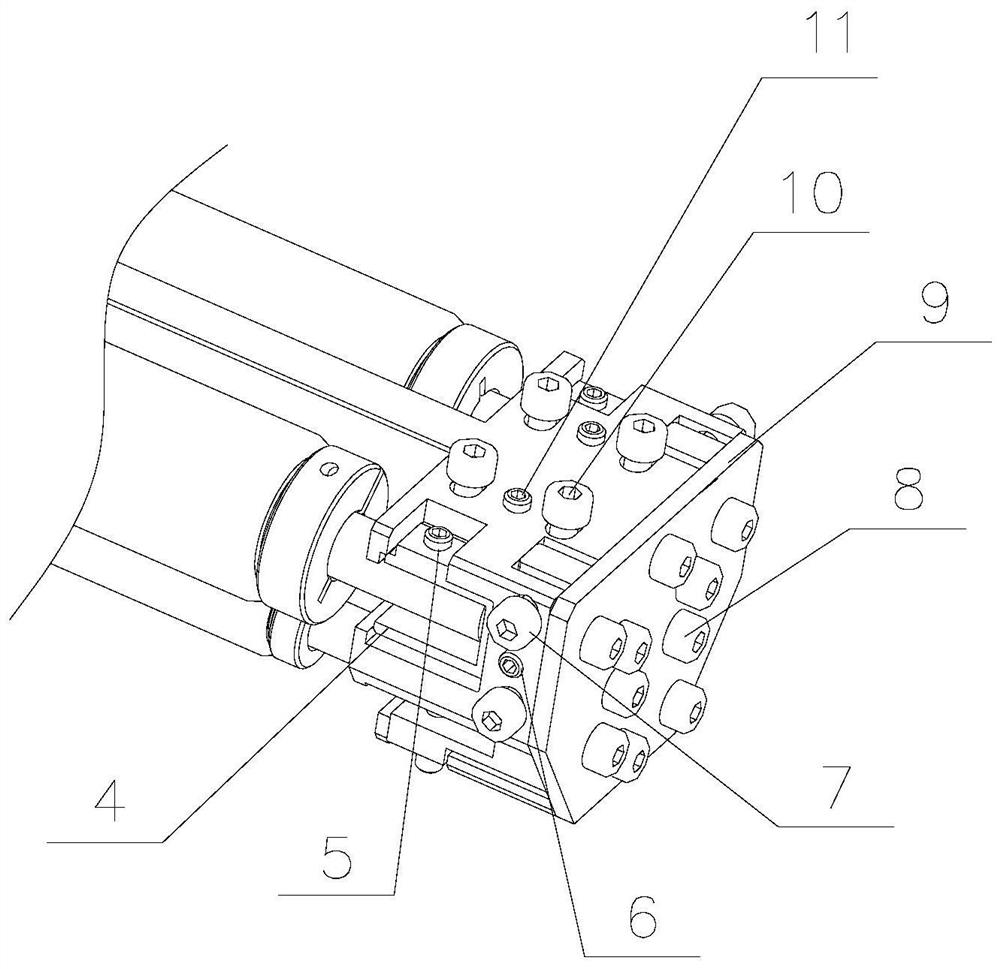

[0029] Such as figure 1 and figure 2 As shown, a triangular roller mechanism for lithium battery separators and diaphragms, including a seat body 1, a roller assembly 3, an adjustment block 4 and an adjustment assembly;

[0030] The adjustment block 4 and the adjustment assembly are arranged at one end of the base body 1, one end of the roller passing assembly 3 is arranged on the adjustment block 4, and the other end is arranged on the base body 1, and the adjustment assembly is used for Adjust the position of the adjusting block 4 to adjust the position of the roller assembly 3 .

[0031] The triangular roller mechanism used in the embodiment of the present invention for separating the pole piece and the diaphragm direction of the lithium battery can be applied to the lithium battery winding equipment to separate the pole piece and the diaphragm direction before winding, and can better separate and shape the pole piece diaphragm direction, to prevent the friction of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com