A large battery mixing process

A battery and mixing technology, applied in the repair/maintenance of secondary batteries, measuring electricity, measuring electrical variables, etc., can solve the problems of low battery matching efficiency and short service life of battery packs, and achieve the improvement of battery output and consistent improvement. Sex, the effect of reducing the number of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

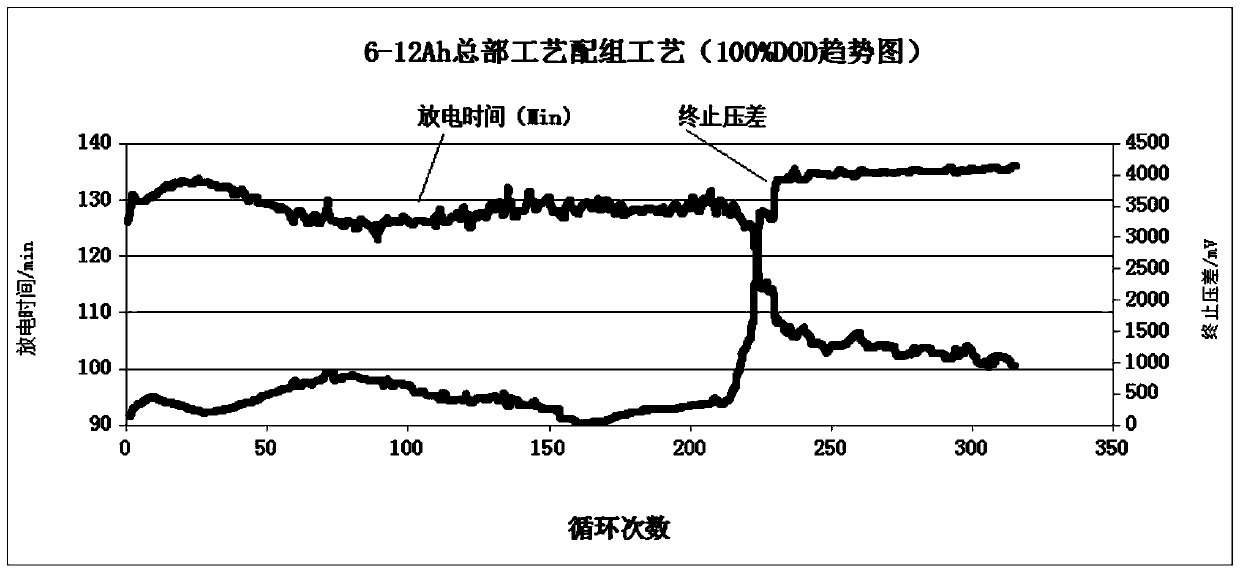

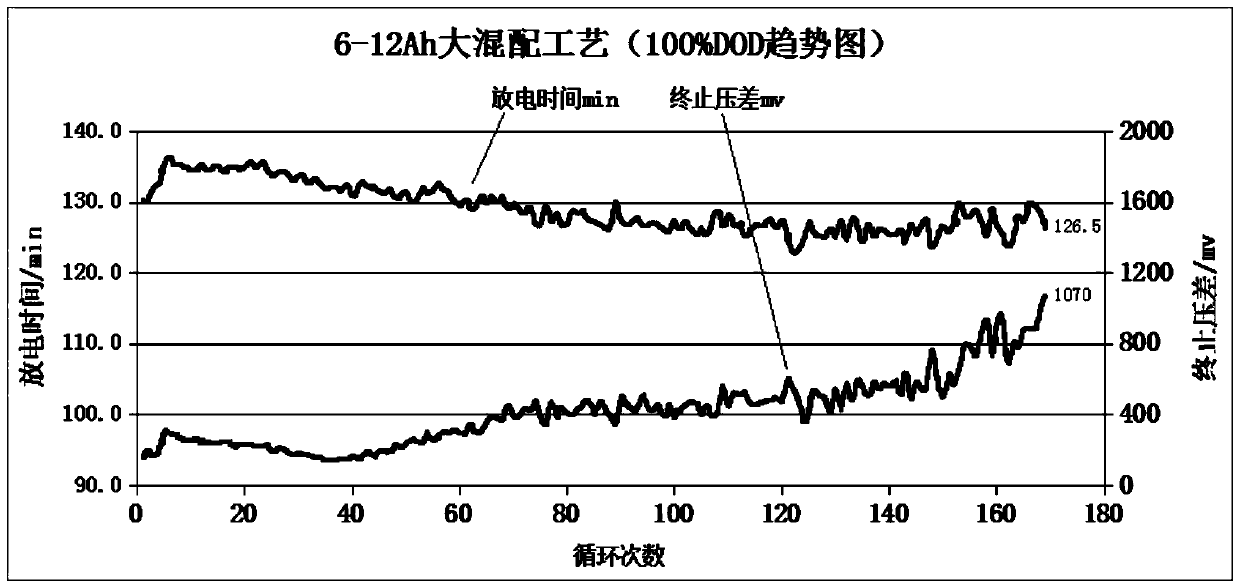

[0031] The 6-DZM-12 type of battery to be mixed is subjected to a large-scale battery mixing process, which is successively carried out through battery charge and discharge and detection, free acid extraction, acid extraction sampling inspection, online charging verification, and battery assembly process to form a battery pack. The battery pack that has undergone the large-scale battery mixing process and the battery pack that has not undergone the large-scale battery mixing process of this model are detected, and the data graphs of discharge time, termination voltage and cycle times are obtained. The battery pack of the 6-DZM-12 model in this embodiment The cycle life data picture before the large-scale mixing is implemented figure 1 As shown, the cycle life data of the 6-DZM-12 battery pack after the large-scale mixing is implemented is as follows figure 2 shown.

[0032] refer to figure 1 and figure 2, by comparison, the 6-DZM-12 type battery before the implementation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com