A Strongly Sealed Explosive Bolt Device

An explosive bolt and strong sealing technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of easy sealing failure and low reliability of explosive bolt sealing, avoid failure, enhance anti-explosion sealing ability, design Reliable and effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

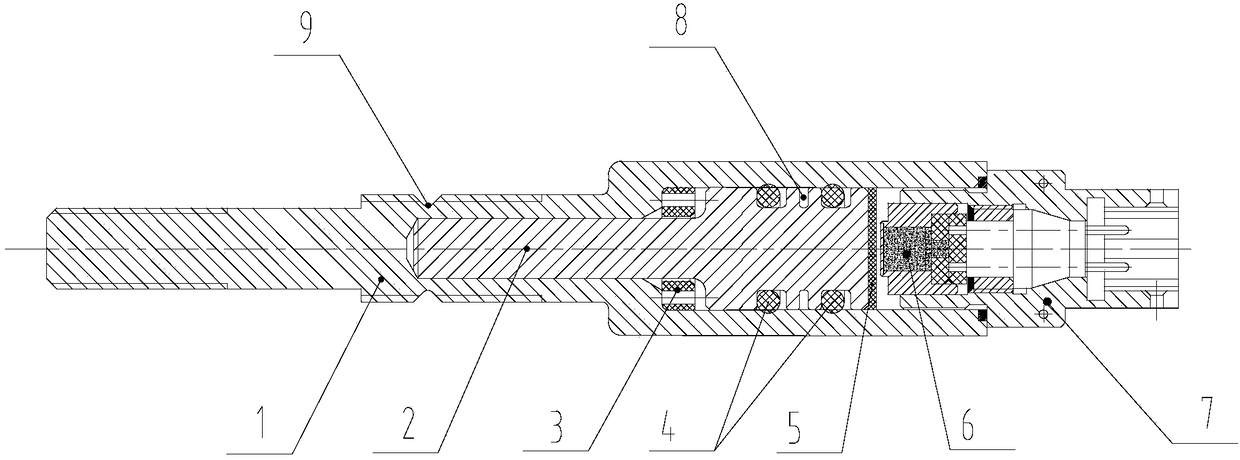

[0024] Such as figure 1 As shown, a strong sealing explosive bolt device includes a bolt housing 1, a piston 2, a buffer ring 3, an O-shaped rubber ring 4, a non-metallic gasket 5, a propellant 6 and an igniter 7. The piston 2 and the buffer ring 3 are installed in the cavity of the bolt housing 1. The V-shaped groove 9 is designed on the bolt housing 1 as the weak link of strength. The piston 2 is designed with two sealing grooves and a detonation groove 8, O-shaped The rubber rings 4 are respectively installed in the two sealing grooves of the piston 2, the non-metallic gasket 5 is pasted on the bottom end surface of the piston 2 by curing glue, the explosive 8 is installed in the igniter 7, and then connected with the bolt housing 1 through thread fit . After the igniter 7 is energized and detonated, the explosive 6 is ignited to generate high-temperature and high-pressure gas, which pushes the piston 2 to move, and the piston quickly squeezes the buffer ring 3 and hits th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com