Patents

Literature

37 results about "Pyrotechnic fastener" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pyrotechnic fastener (also called an explosive bolt, or pyro, within context) is a fastener, usually a nut or bolt, that incorporates a pyrotechnic charge that can be initiated remotely. One or more explosive charges embedded within the bolt are typically activated by an electric current, and the charge breaks the bolt into two or more pieces. The bolt is typically scored around its circumference at the point(s) where the severance should occur. Such bolts are often used in space applications to ensure separation between rocket stages, because they are lighter and much more reliable than mechanical latches.

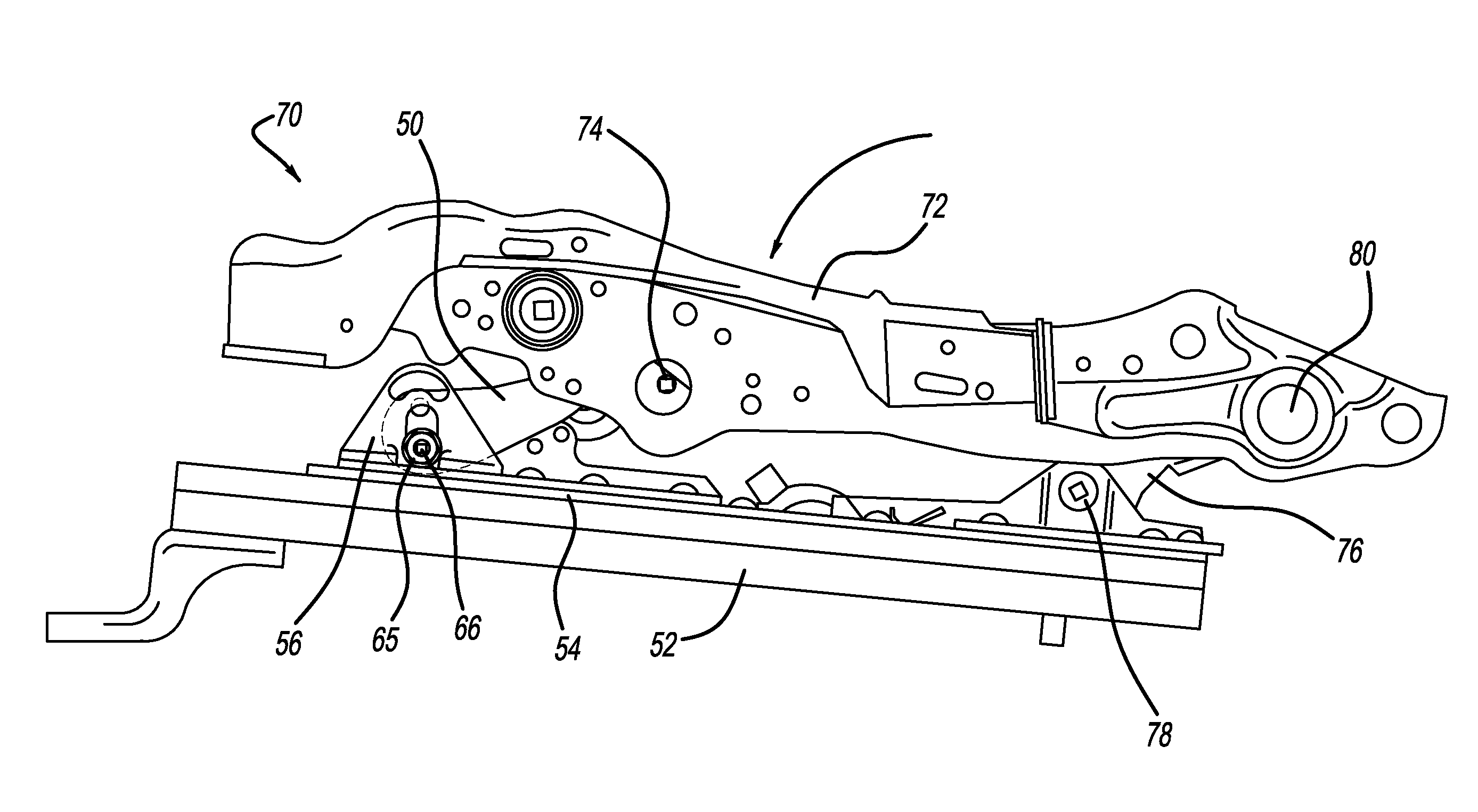

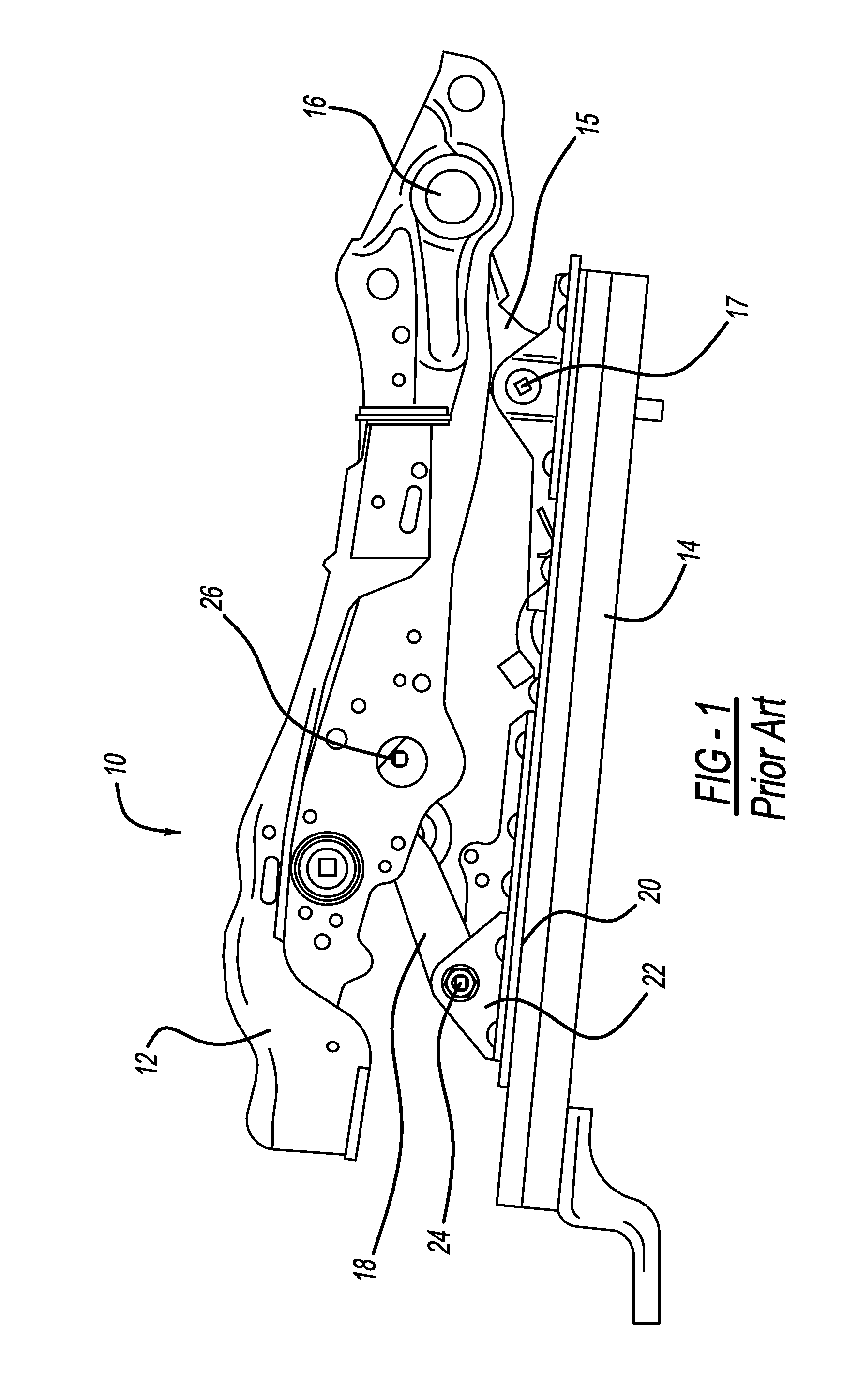

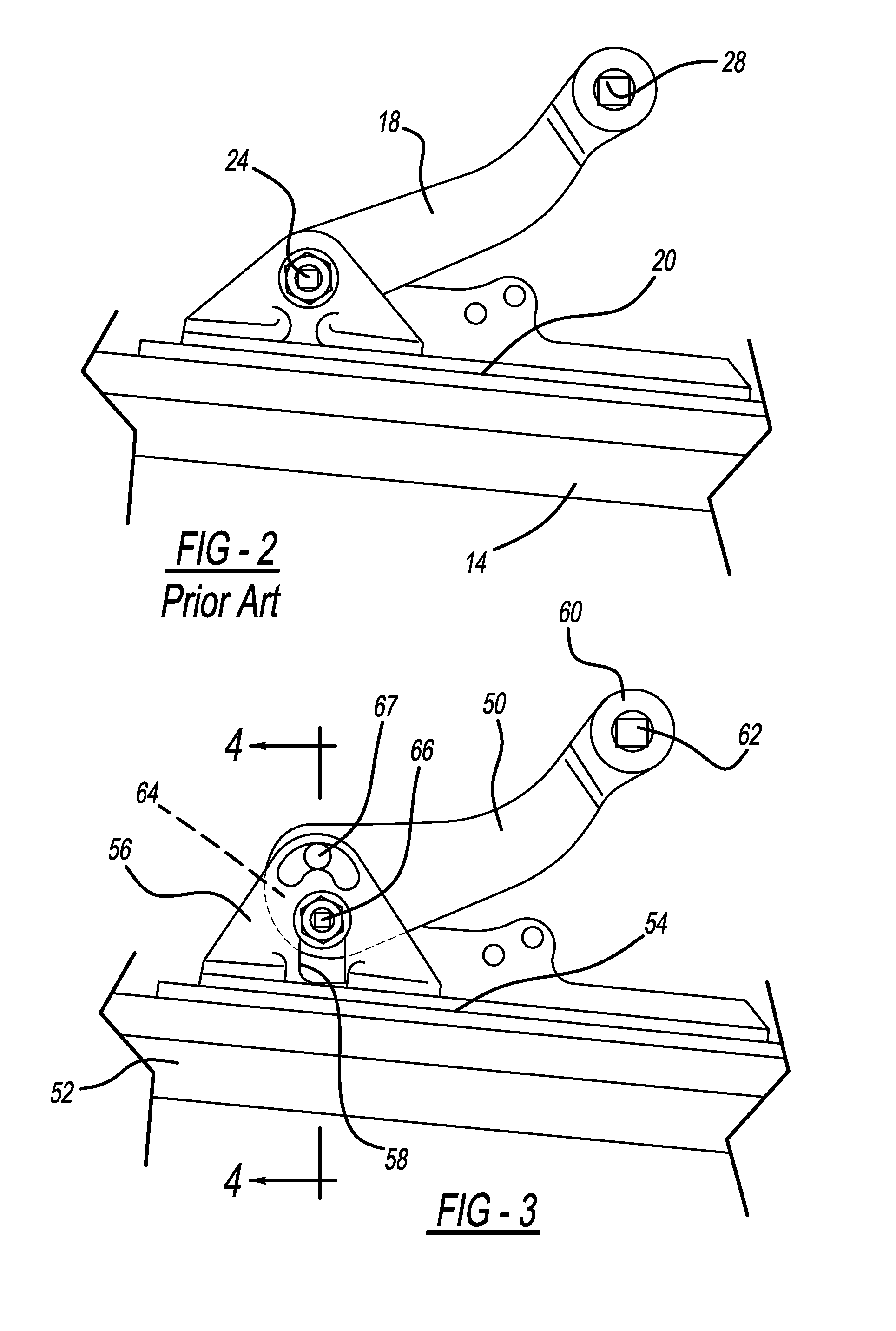

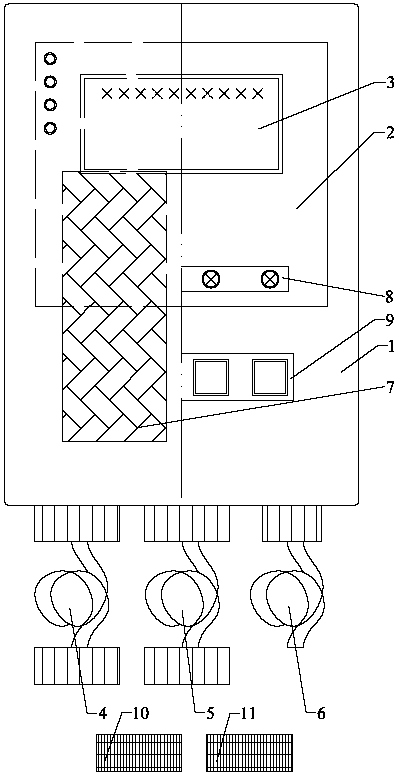

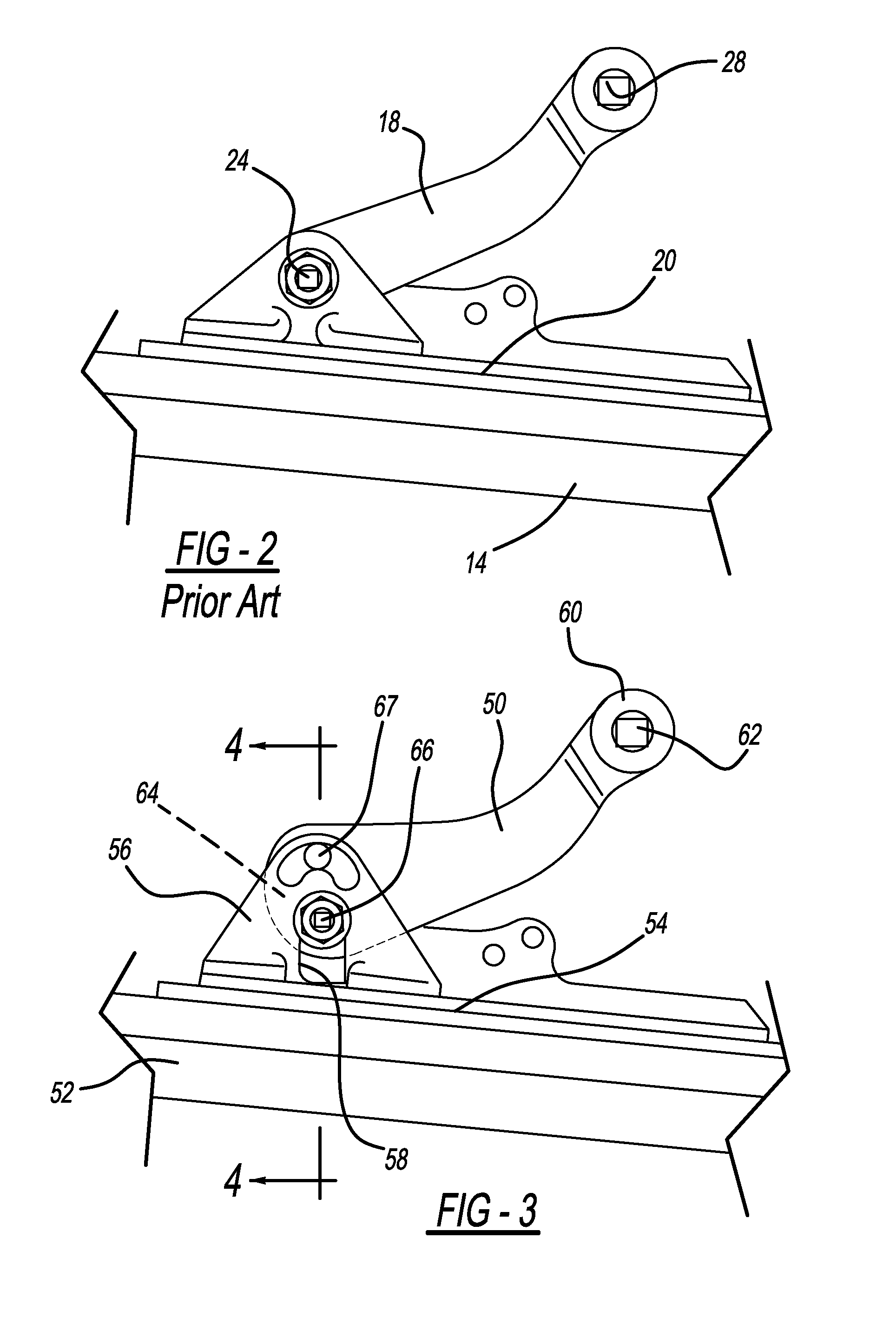

Pyrotechnic fastener seat arrangement for unbelted occupant protection

ActiveUS20150239373A1Improved unbelted occupant safety protectionLowering the unbelted occupantVehicle seatsPedestrian/occupant safety arrangementFastenerPyrotechnic fastener

A seat assembly including a seat pan that drops vertically in the event of a frontal impact event to help safeguard against the head of an unbelted seat occupant striking the headliner, windshield or other components of the vehicle. The seat assembly includes a seat pan attached to a seat track. The seat track further includes an attachment bracket. A swing linkage movably connects the seat pan with the seat track by a movable fastener. A slot is formed in the bracket through which at least a part of the movable fastener passes. A pyrotechnic fastener also attaches the swing linkage to the bracket. In a frontal impact event the pyrotechnic fastener is caused to explode thus separating the pyrotechnic fastener into two parts and allowing the swing linkage and its attached seat pan to drop vertically relative to the seat track, thereby lowering the unbelted occupant.

Owner:FORD GLOBAL TECH LLC

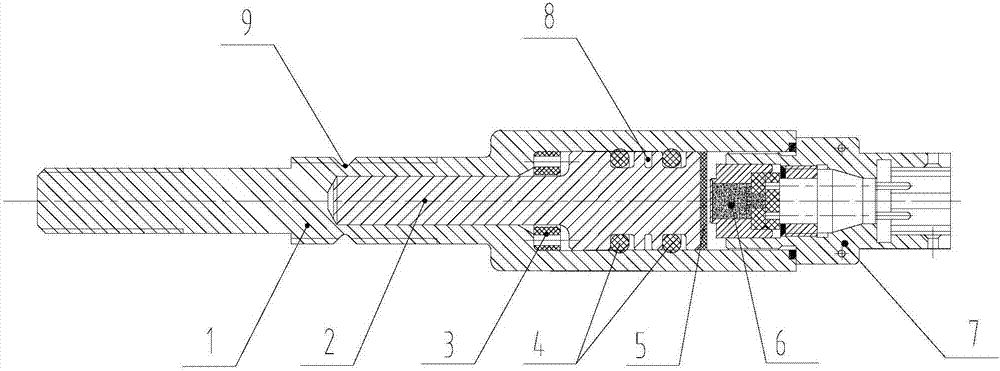

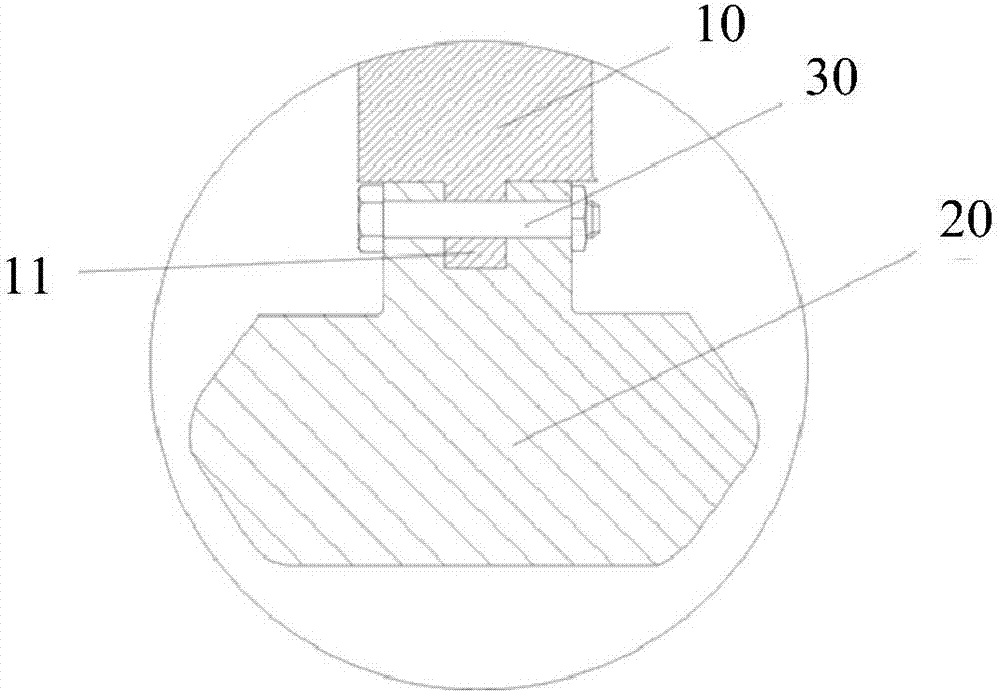

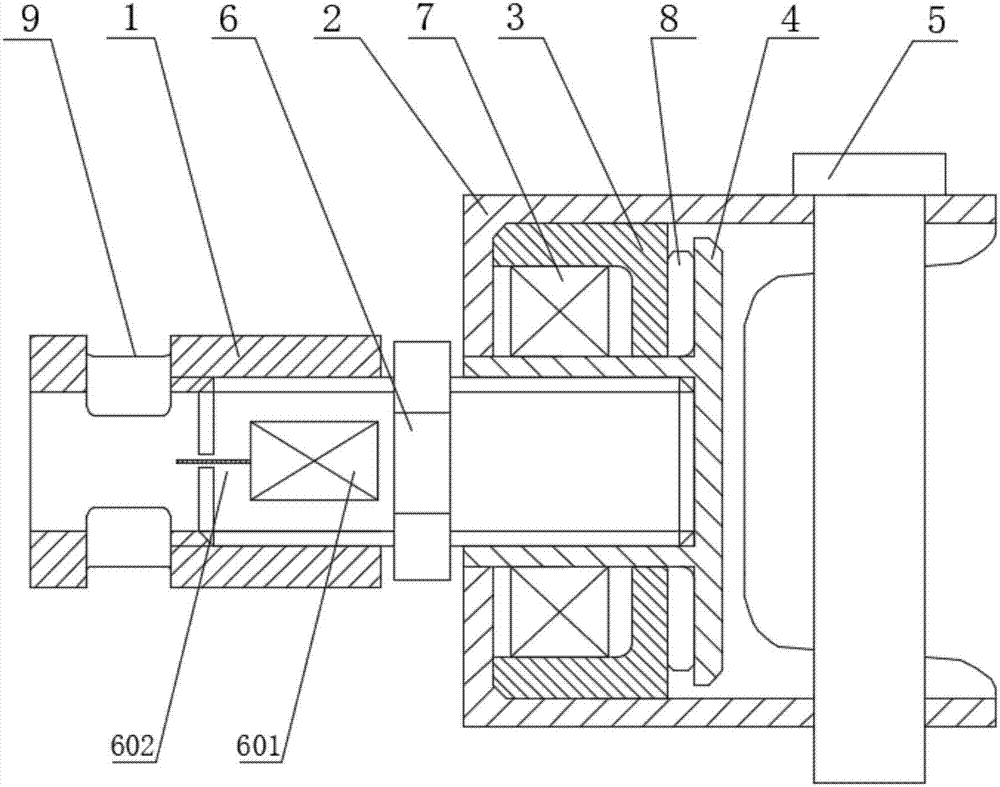

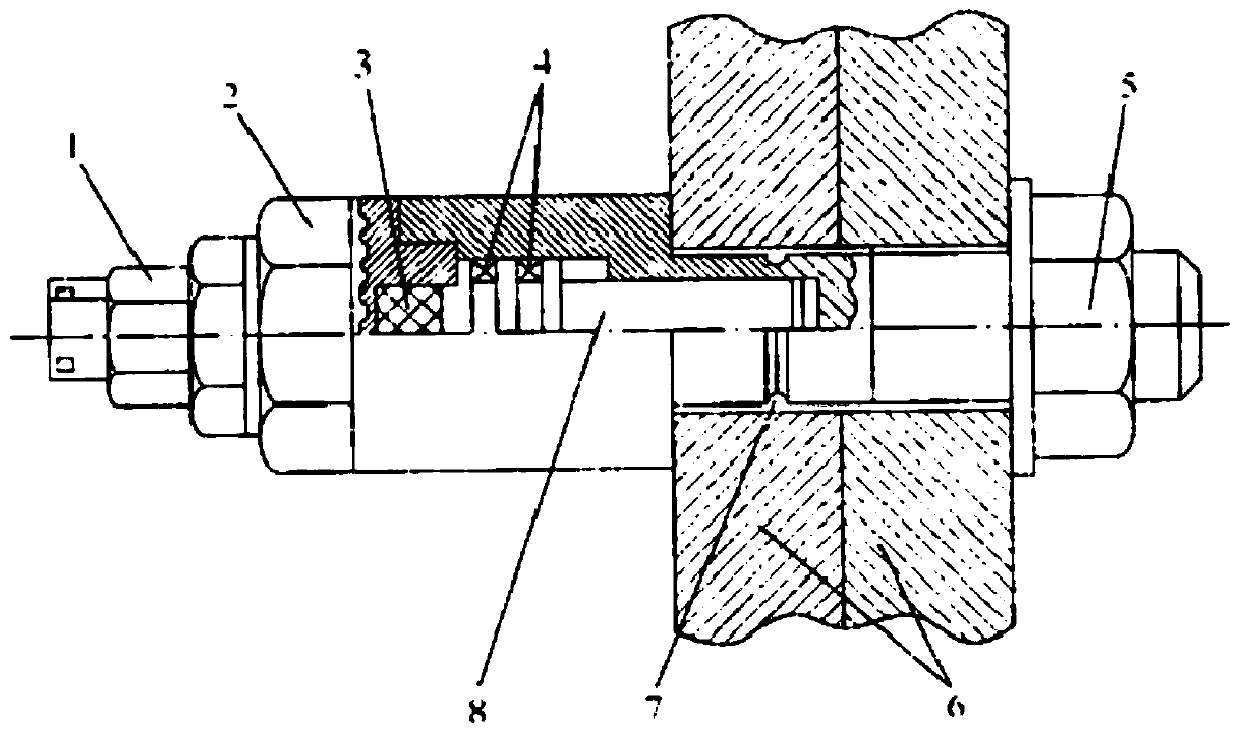

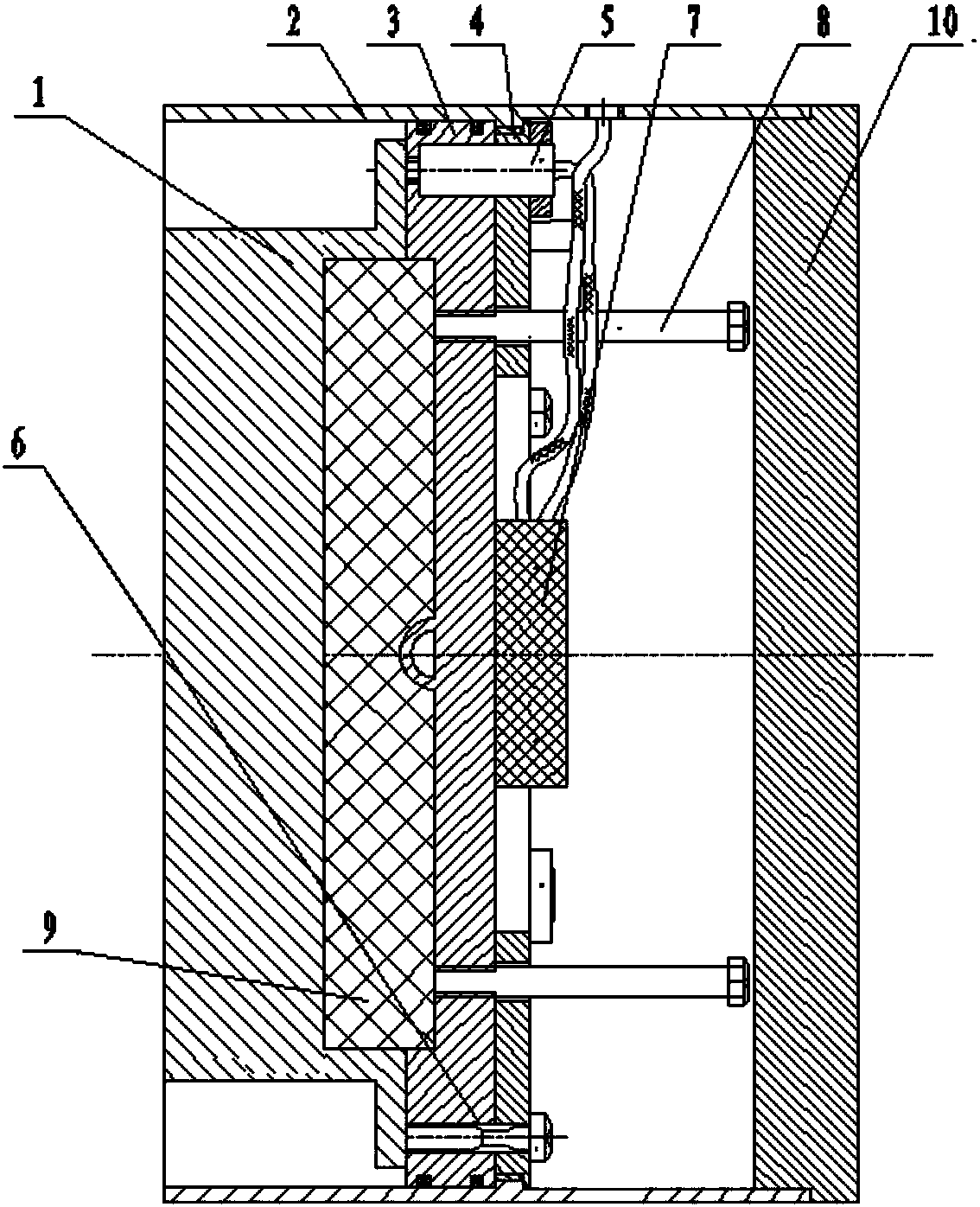

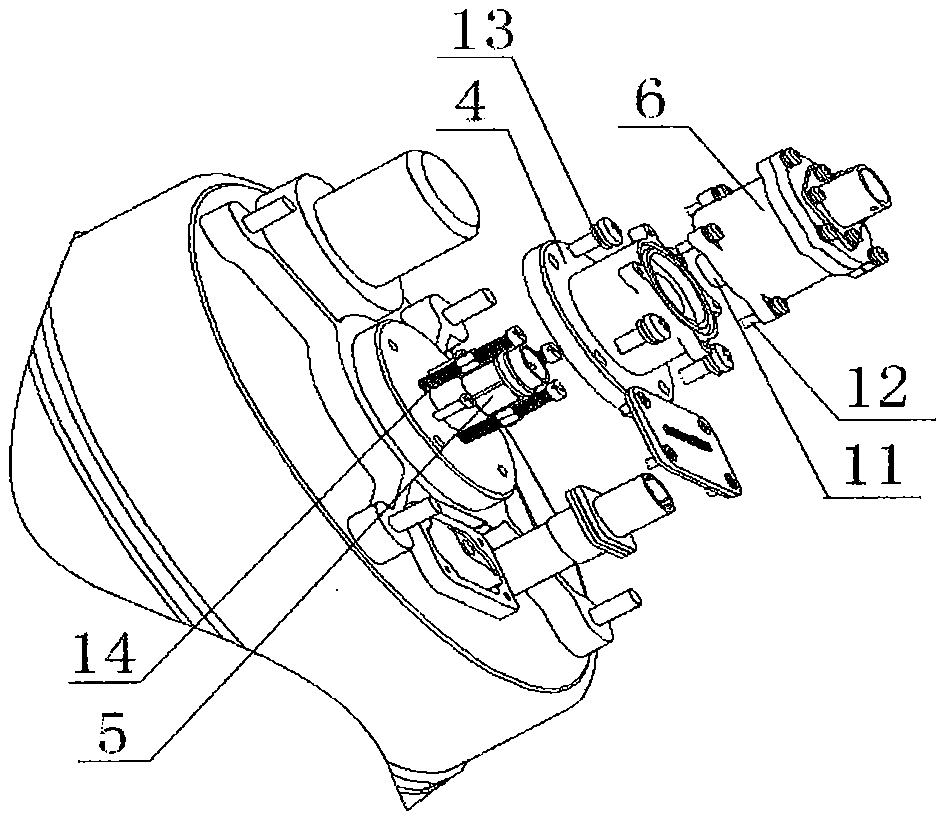

Strong seal explosion bolt device

ActiveCN107191459AEnhanced anti-explosion sealing abilityAvoid failureScrewsSelf-propelled projectilesRubber ringEngineering

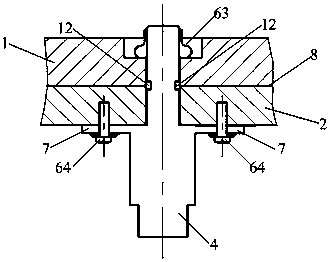

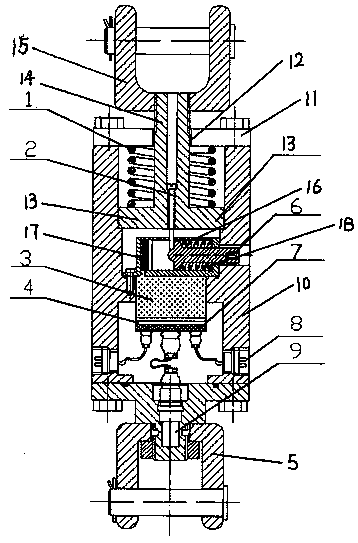

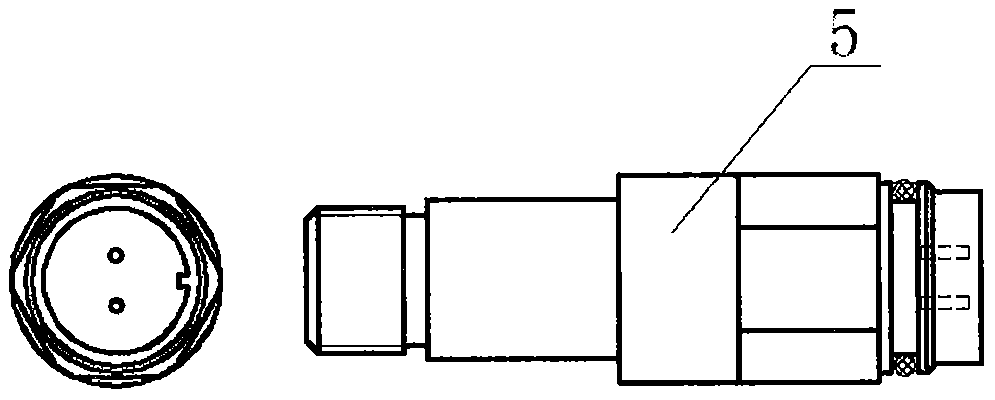

The invention discloses a strong seal explosion bolt device. A bolt shell, a piston, a buffer ring, O-shaped rubber rings, a nonmetal gasket, explosive and an igniter are sequentially mounted on a main shaft from left to right; the piston and the buffer ring are mounted in a containing cavity of the bolt shell; a V-shaped groove is designed in the bolt shell to serve as a strength weak link; two sealing grooves and an explosion decompression groove are designed in the piston; the double O-shaped rubber rings are mounted in the two sealing grooves of the piston correspondingly; the nonmetal gasket is pasted on the bottom end face of the piston through curing glue; and the explosive is mounted in the igniter, and then the igniter is connected with the bolt shell in a thread fit mode. The situation that deflagration gas generated by the explosive is leaked from the V-shaped groove after a bolt is broken can be prevented, and a very good sealing effect is achieved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

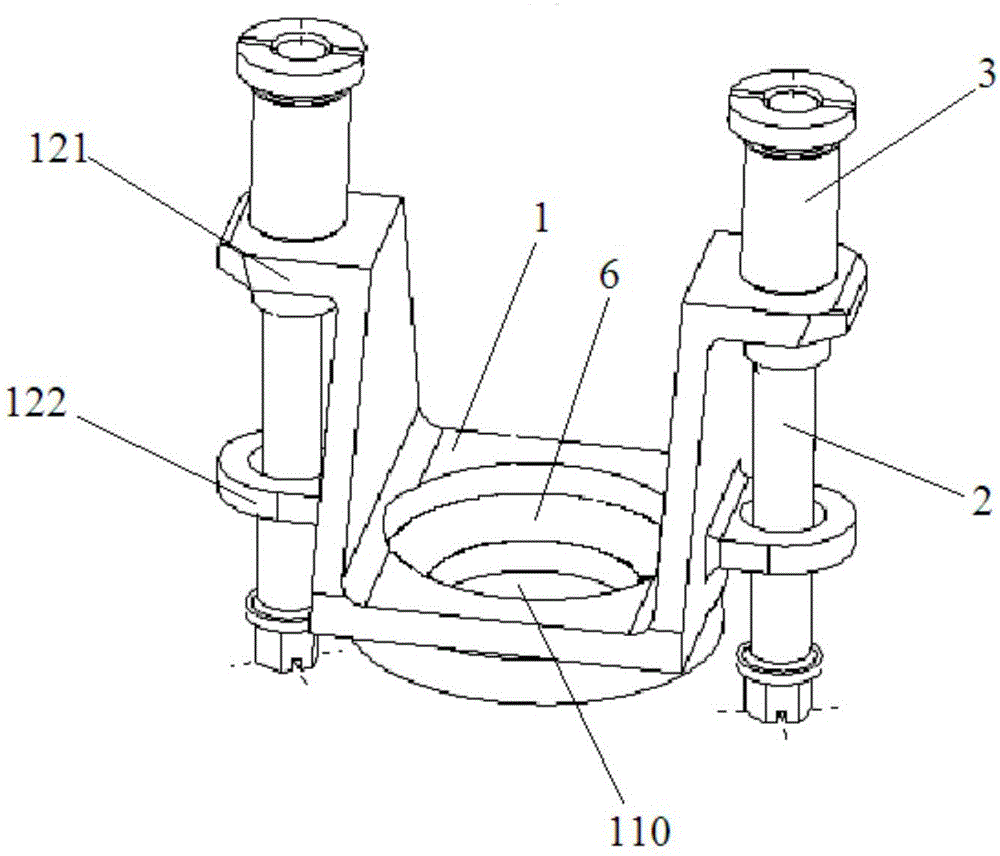

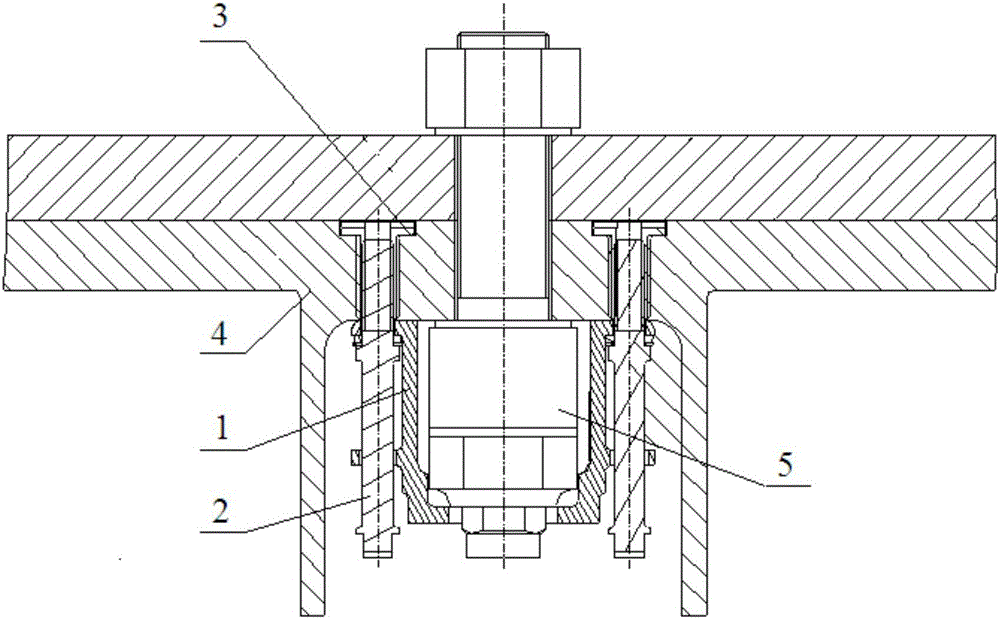

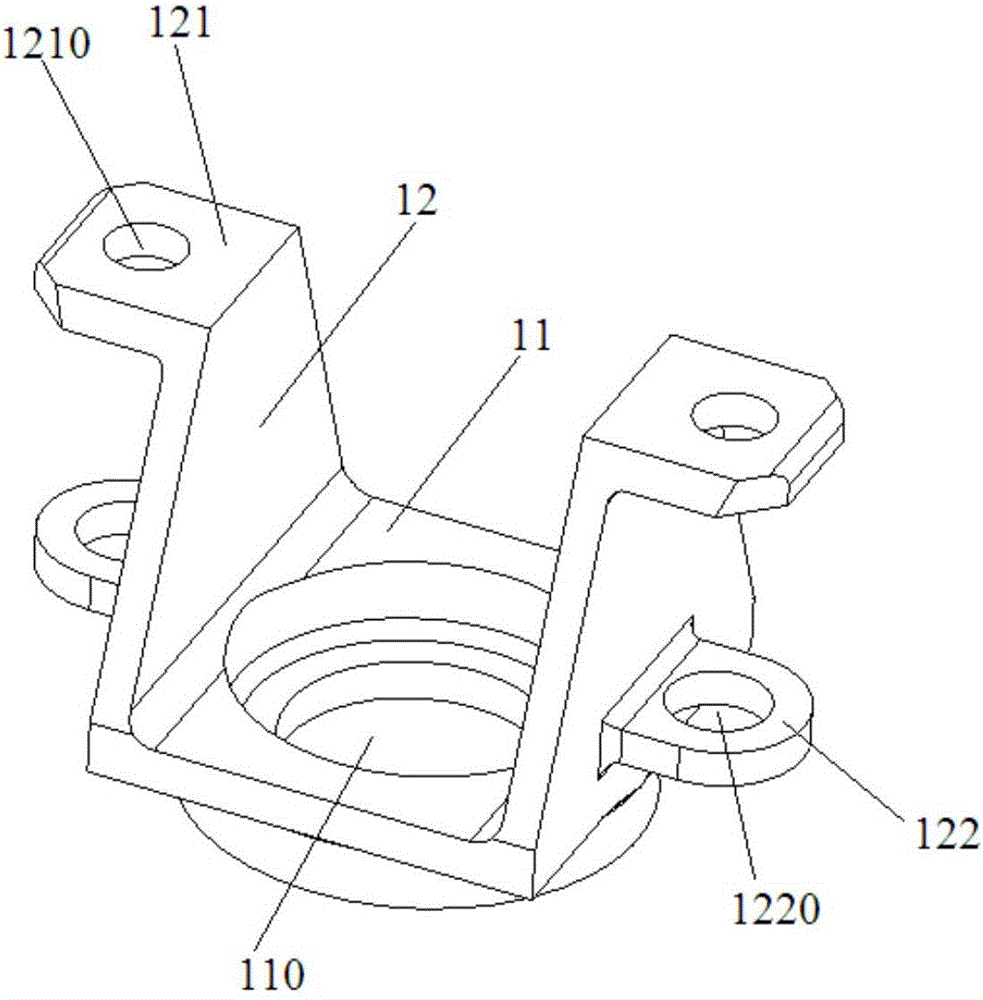

Explosive bolt acquirer

InactiveCN106403733AGuaranteed impact resistanceEasy to installSelf-propelled projectilesHigh volume manufacturingEngineering

The invention relates to the technical field of projectile body structural design, in particular to an explosive bolt acquirer. The explosive bolt acquirer comprises a support and an installation bolt, the support is in an inversed-n shape and comprises a base plate and two side plates, the side plates and the two ends of the base plate are integrally molded, the upper ends of the side plates extend to the outer sides to be provided with end edges, and installation holes are formed in the end edges; the installation bolt penetrates the installation holes to be connected with a shell end frame so that the support can be fixed to the lower surface of the shell end frame, the base plate is provided with a buffer hole, and a bolt head of an explosive bolt is located between the two side plates and is embedded into the buffer hole. Compared with a traditional explosive bolt acquiring structure, the explosive bolt acquirer is convenient and rapid to install, the design, analyzing and testing cost is reduced, projectile body structural design quick response and cost reduction are achieved, material selecting and machining can be separated from material selecting and machining of a projectile body overall bin, the machining difficulty is reduced, selectable materials are many, the production efficiency is improved, productization is facilitated, and the large-batch production efficiency is high.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

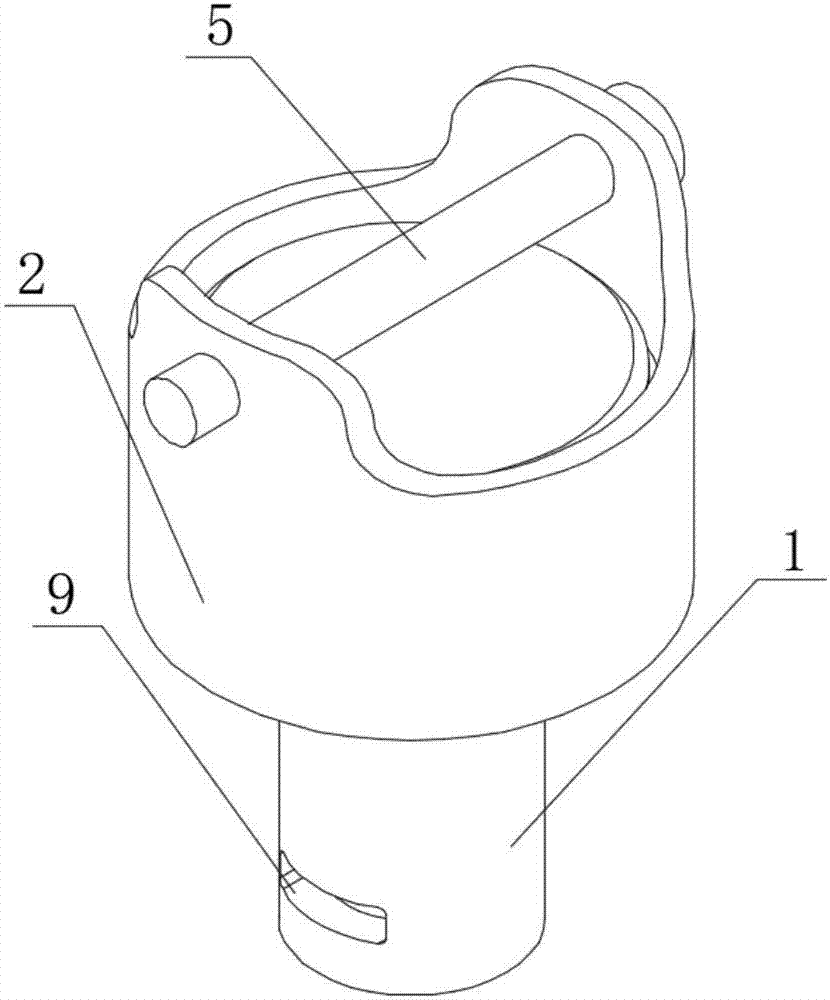

Sampling basket throwing device of manned submarine

A sampling basket throwing device of a manned submarine comprises a spherical hinge support provided with a first groove. A spherical head at one end of a connecting pin is jointed with the first groove, the spherical head and the first groove can be disengaged from each other, the other end of the connecting pin is connected with a second groove, the second groove comprises two split-half grooves I formed in a rotational seat and a fixed seat, the rotational seat is hinged to a connecting frame, the rotational seat rotates to enable the two split-half grooves I to be coupled or uncoupled, a first through hole is formed in the fixed seat, a second through hole is formed in the rotational seat, the first through hole communicates with the second through hole axially to form an integral through hole, a pull rod extends into the integral through hole through one end of the integral through hole, the extension end of the pull rod is provided with an internal threaded hole, an explosive bolt extends into the integral through hole through the other end of the integral through hole, the rotational seat and the fixed seat are fixedly connected through the threaded connection of the explosive bolt and the internal threaded hole, the spherical hinge support and the fixed seat are fixedly connected with the connecting frame, a suspension bracket is connected to the middle pin section of the two ends of the connecting pin in a sleeving way, and the suspension bracket is fixedly connected with a sampling basket. According to the invention, the sampling basket is thrown by adopting electric drive, and the operation is reliable.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

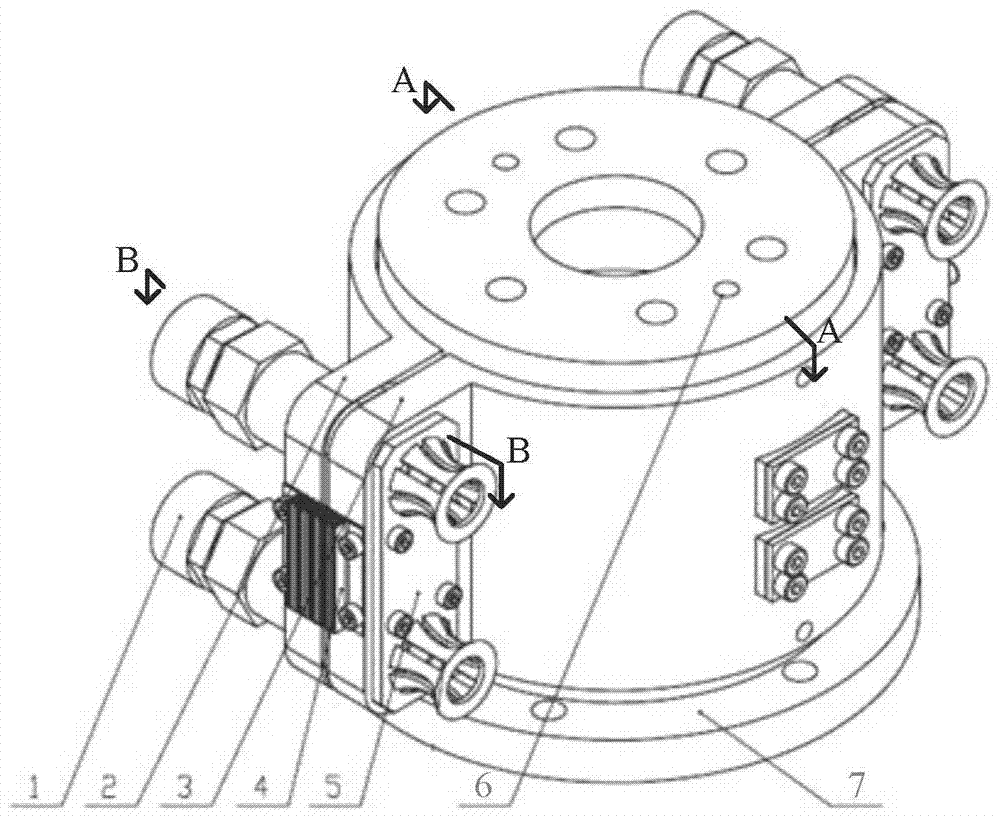

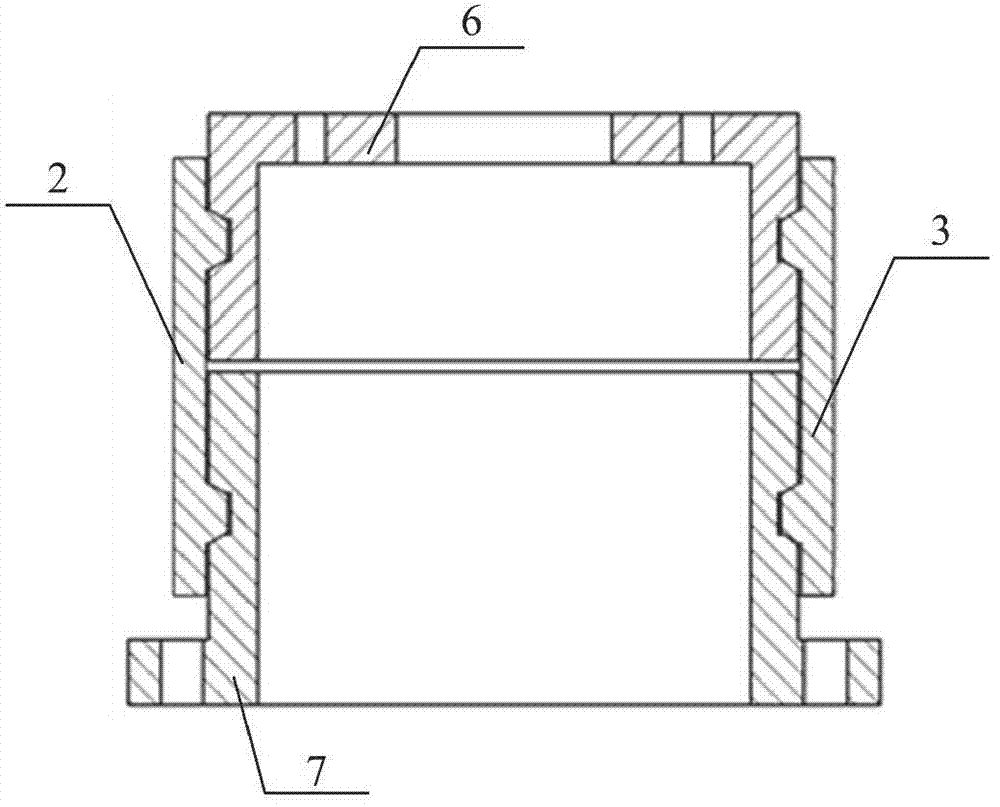

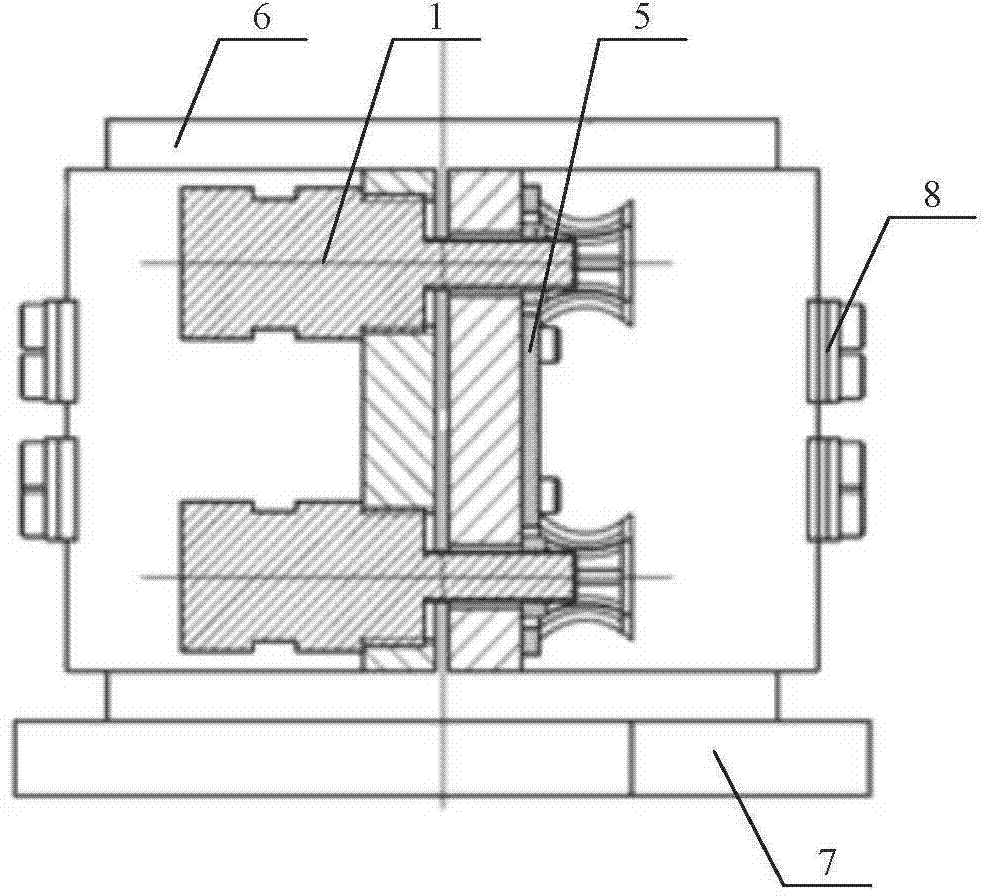

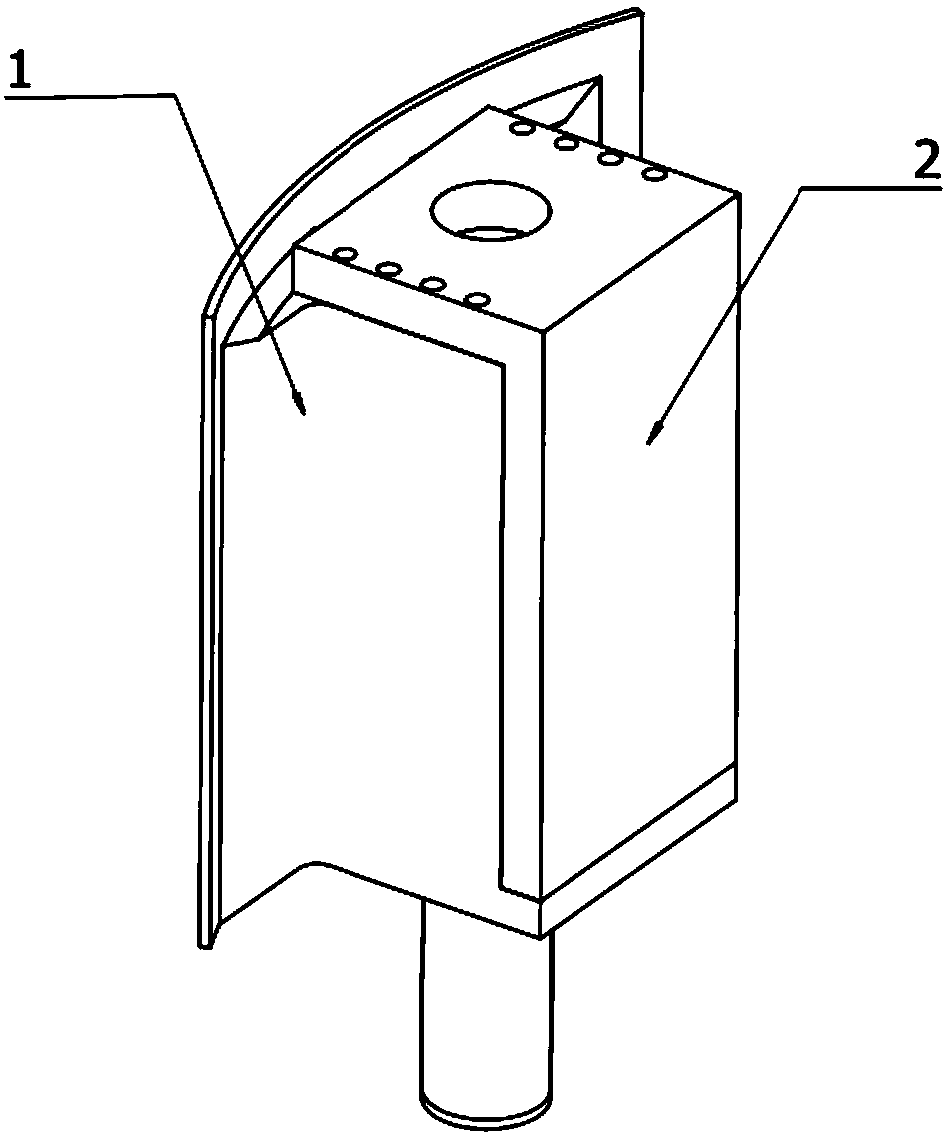

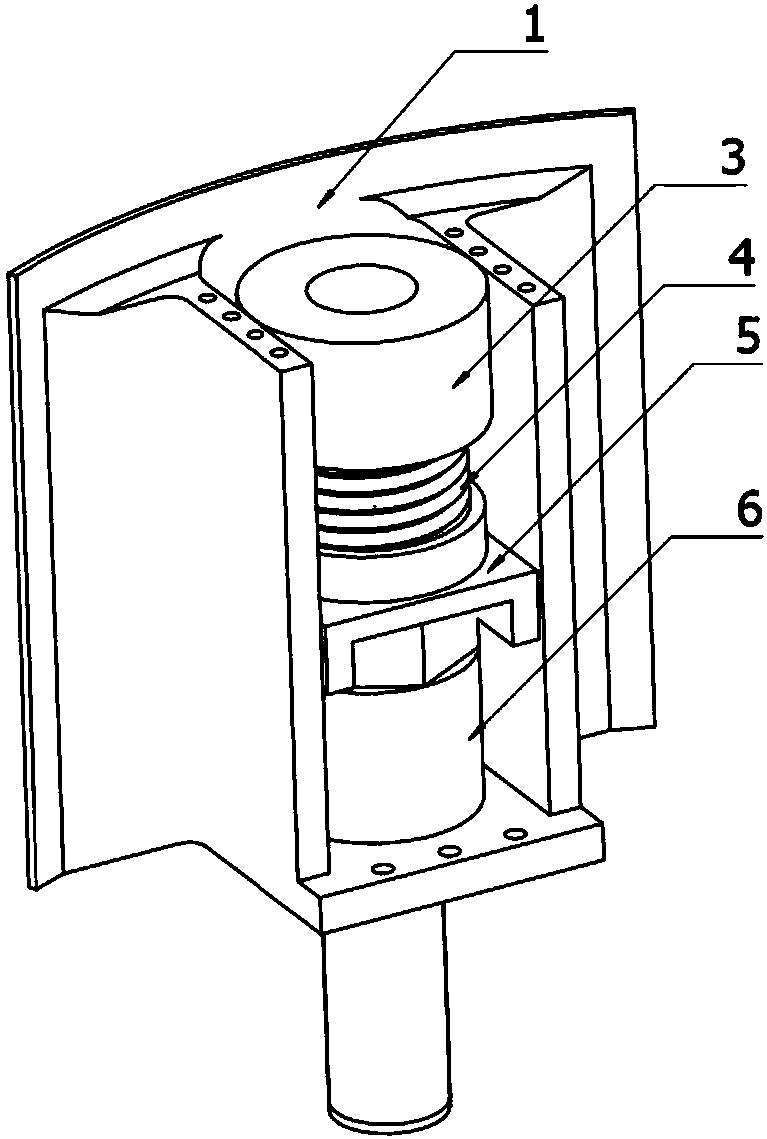

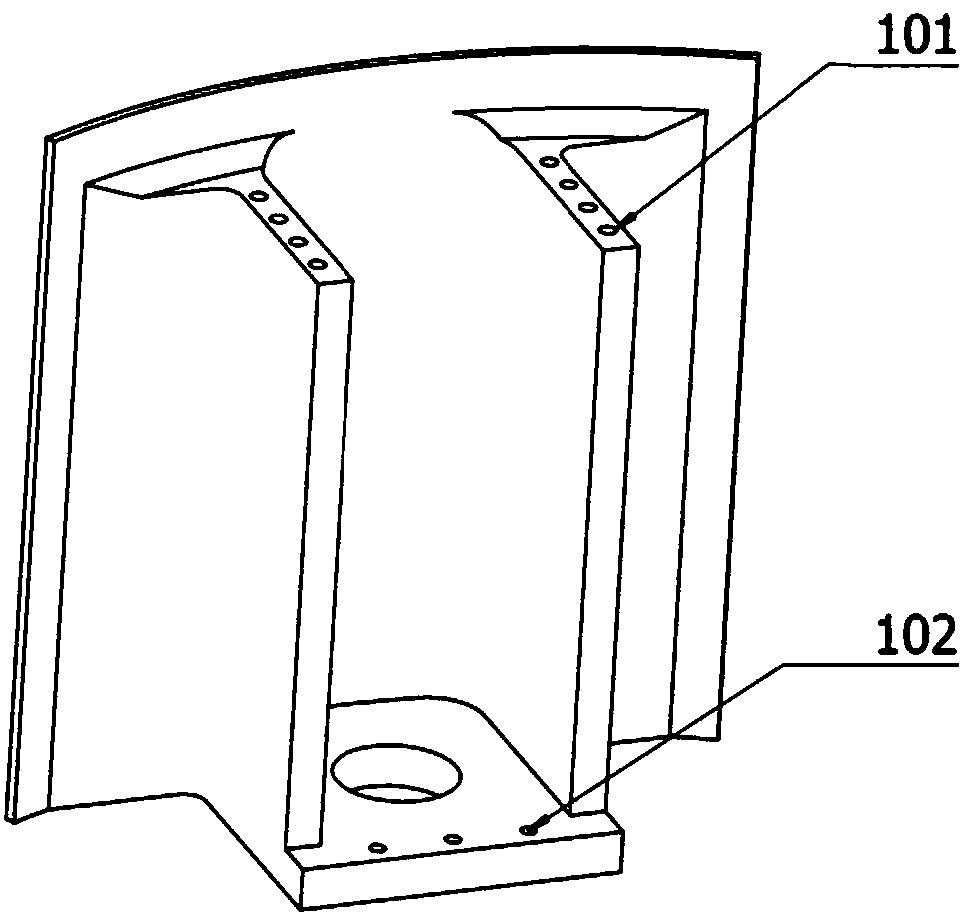

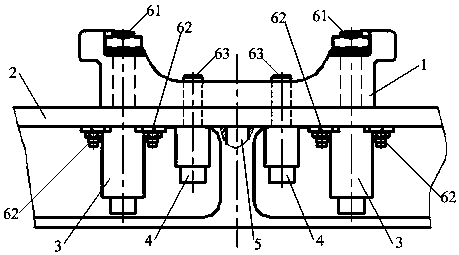

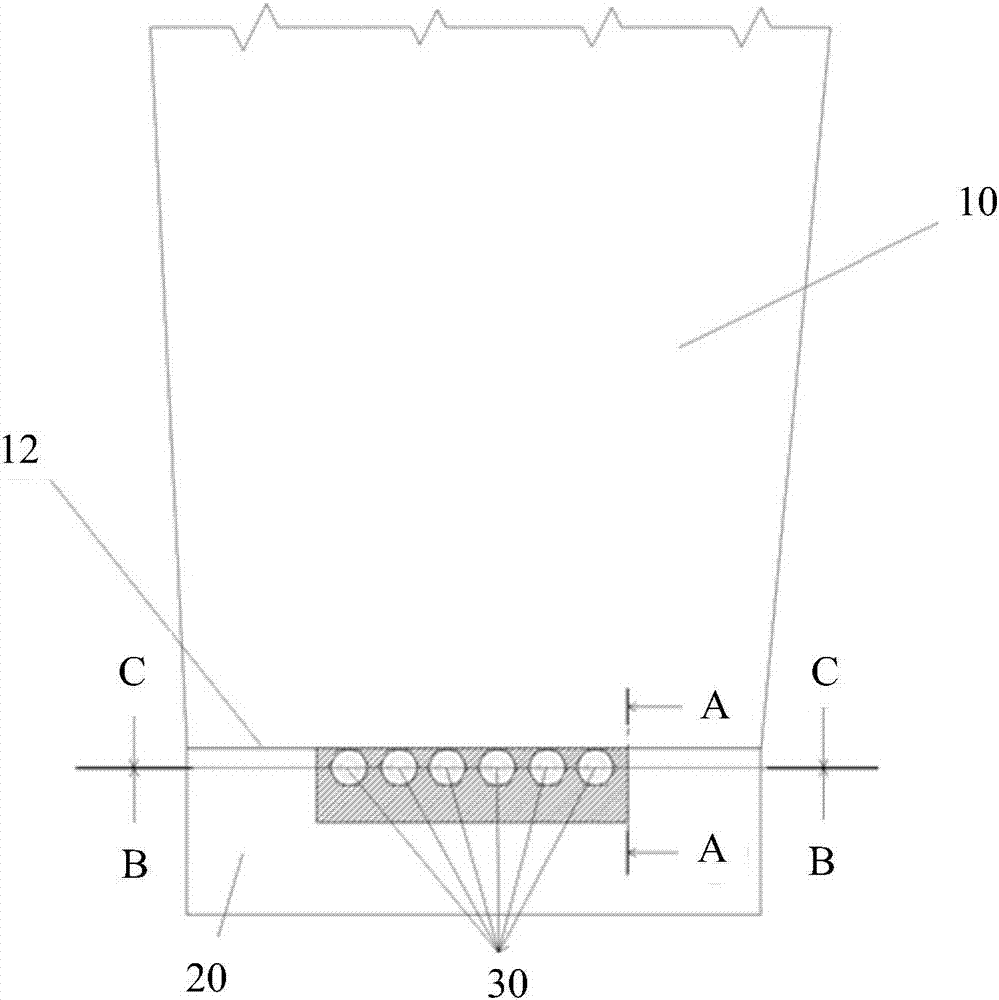

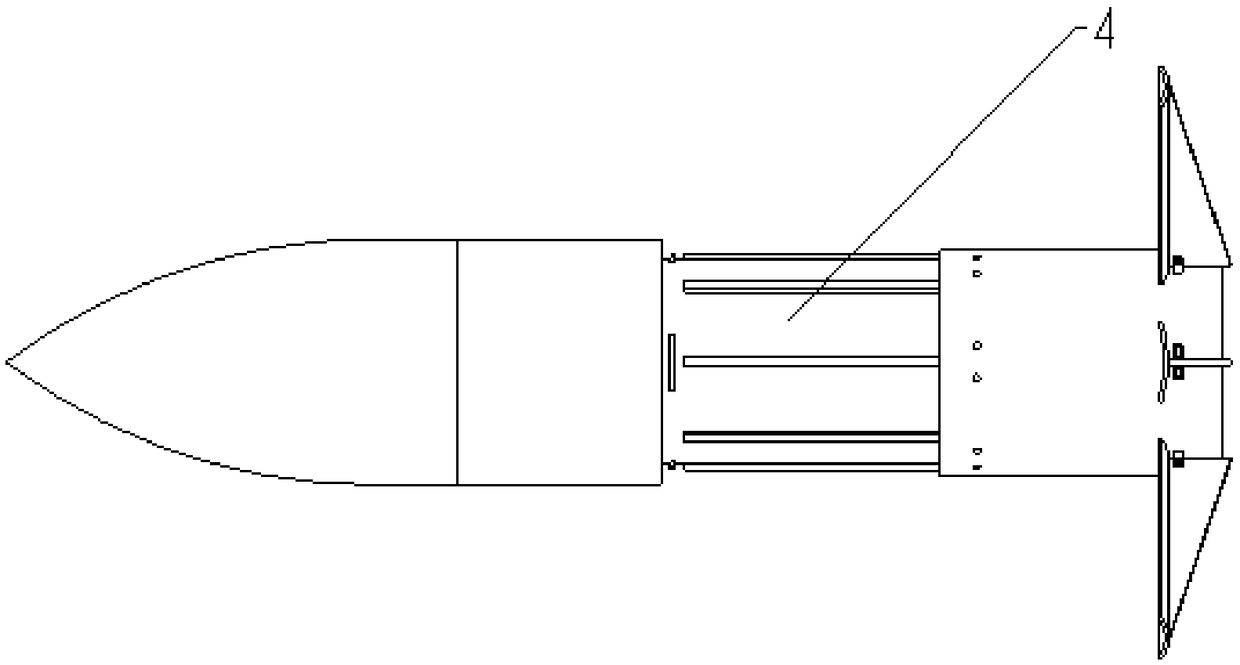

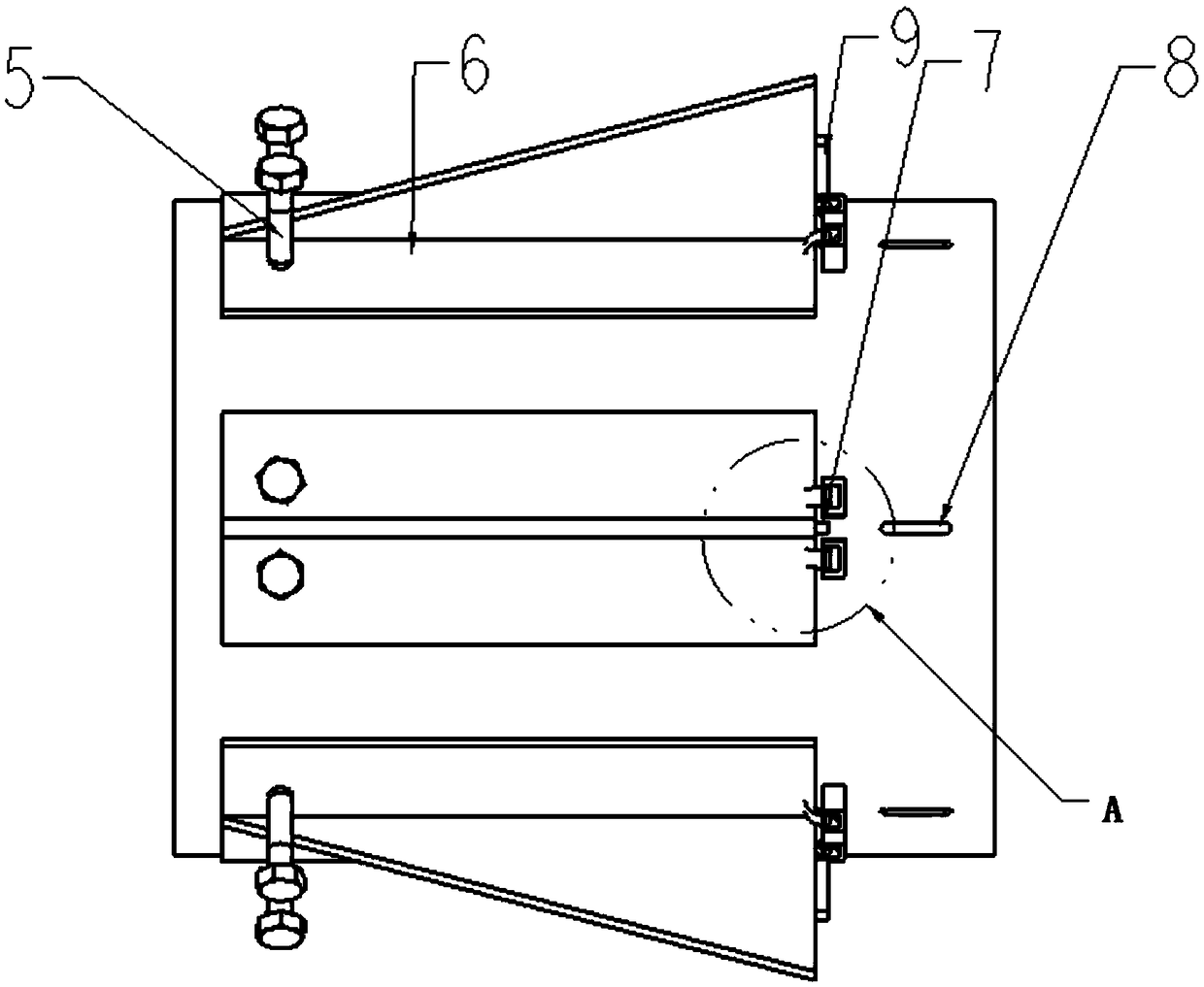

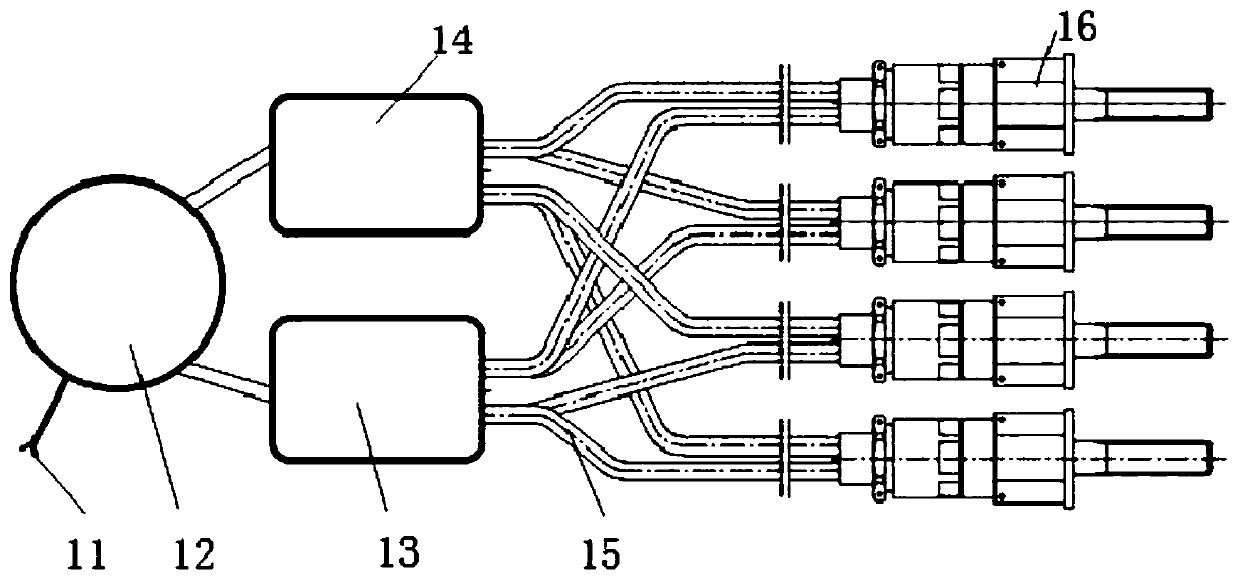

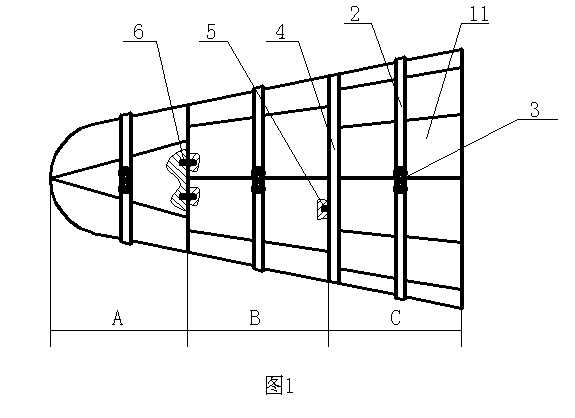

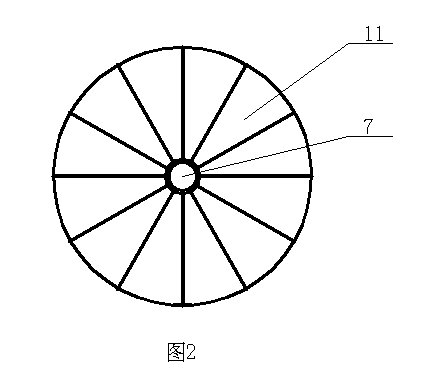

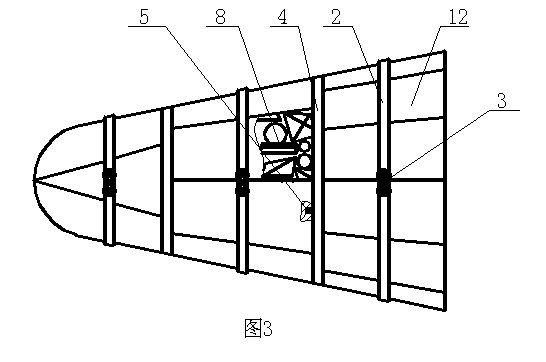

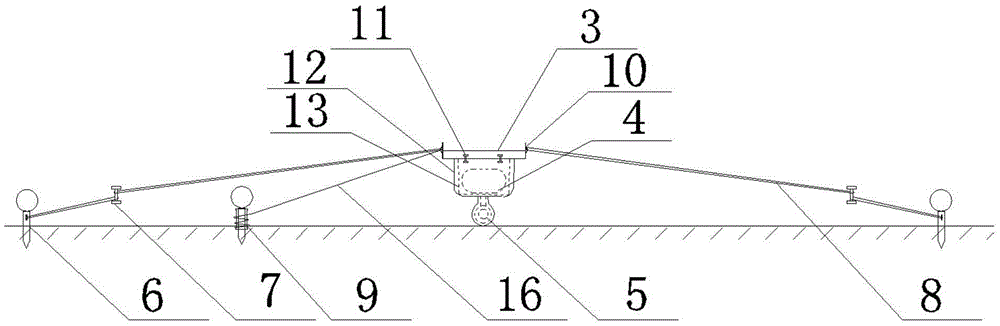

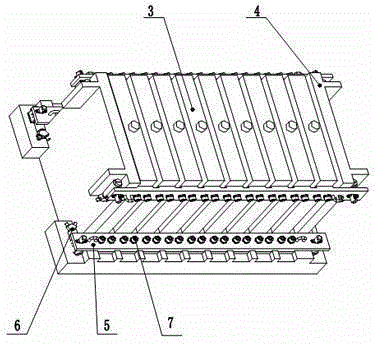

Wrapping tape type unlocking and separation device driven by explosive bolts

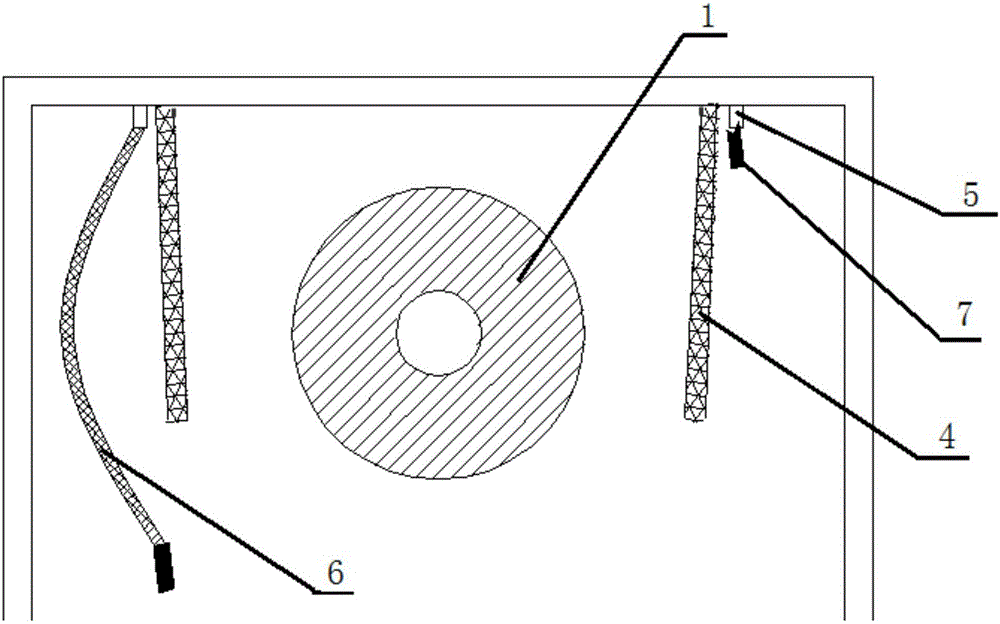

InactiveCN104760709ACompact structureImprove carrying capacityCosmonautic component separationSelf-propelled projectilesState of artScrew thread

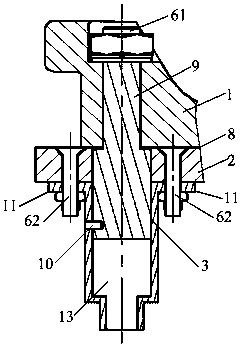

The invention provides a wrapping tape type unlocking and separation device driven by explosive bolts, belongs to the technical field of aerospace, and solves the technical problems that the assembly precision is difficult to guarantee, the structure size is large and the impact is great in the prior art. The wrapping tape type unlocking and separation device comprises the explosive bolts, an upper bracket, a lower bracket, a left wrapping tape, a right wrapping tape, wrapping tape connecting springs and explosive bolt detached body collecting devices. The left wrapping tape is in fitting contact with the upper bracket and the lower bracket. The right wrapping tape is in fitting contact with the upper bracket and the lower bracket. The contact parts, on each of the left side and the right side, of the left wrapping tape and the right wrapping tape are fastened together by two parallel explosive bolts. The wrapping tape connecting springs are in threaded connection with the left tape and the right tape. Each of two ends of the right tape is fixedly connected with one explosive bolt detached body collecting device which is used for collecting detached bodies of the explosive bolts. The wrapping tape type unlocking and separation device driven by the explosive bolts has greatly improved bearing capacity is and is simple and compact structure.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

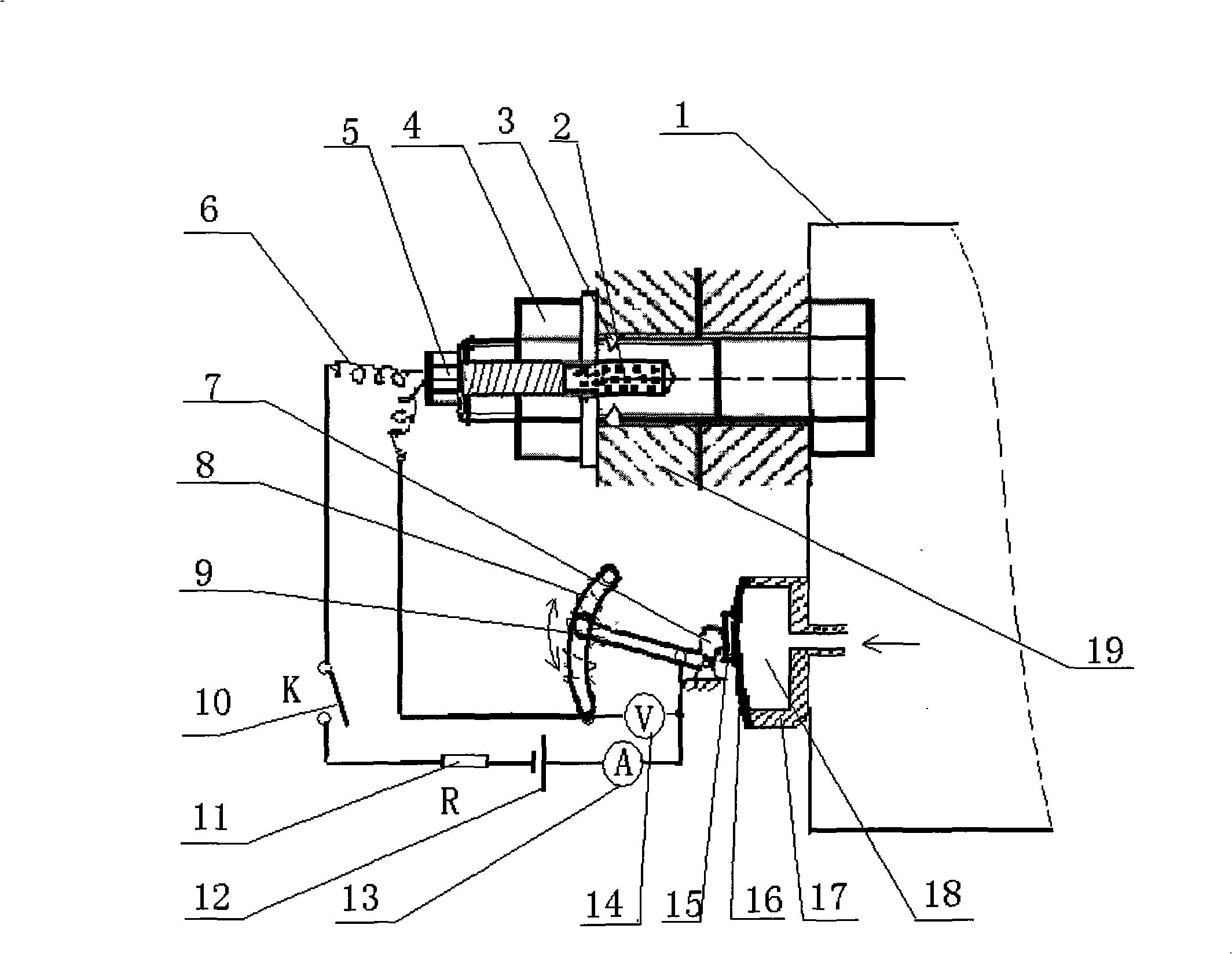

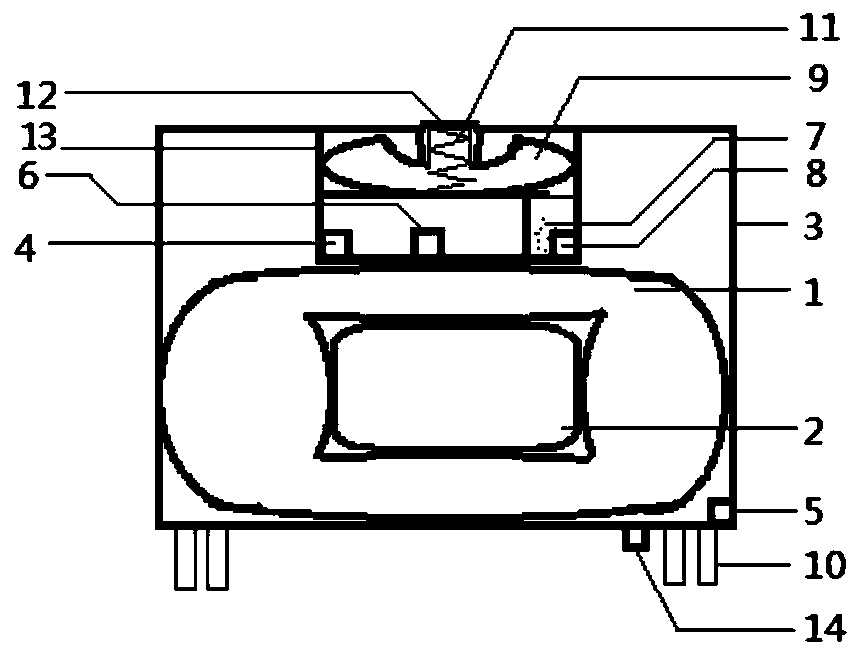

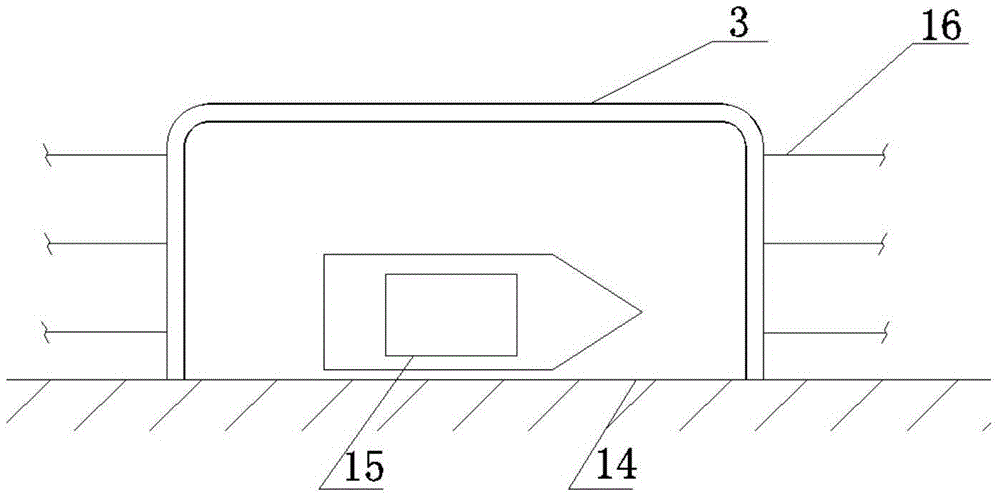

Sensor and explosive bolt on pressure vessel gate

InactiveCN101526134AReduce volumeReduce accidentsContainer filling methodsPressure vesselsElectrical resistance and conductanceCurrent limiting

The invention specifically relates to a sensor and an explosive bolt device on a pressure vessel gate. Main parts are arranged on a hinge of the pressure vessel gate. Major components are arranged on a hinge of the pressure vessel gate. A bolt on the hinge of the pressure vessel gate is changed into an explosive bolt. After the explosive bolt explodes, the pressure vessel gate opens automatically and plays the function of releasing pressure. The pressure vessel cannot explode. Therefore, the function of protecting the pressure vessel is realized. The invention mainly comprises the pressure sensor and the explosive bolt which comprises an explosive (2), a pre-reserved groove (3), a transposition explosive screw (5) and an electrifying conductor (6). A current-limiting resistance, a slide rheostat and a diaphragm (16) of the pressure sensor are arranged in the pressure sensor. The resistance valve can be regulated. Thus, different pressure values can be set to lead to the explosion of the explosive bolt. With the invention adopted, accidents due to the failure of a safety valve can be reduced. The explosive bolt is provided with the pre-reserved groove. Therefore, the volume of wreck is small when the explosive bolt is broken, and equipment around cannot be damaged.

Owner:NANTONG KAISAI BIOCHEM ENG EQUIP

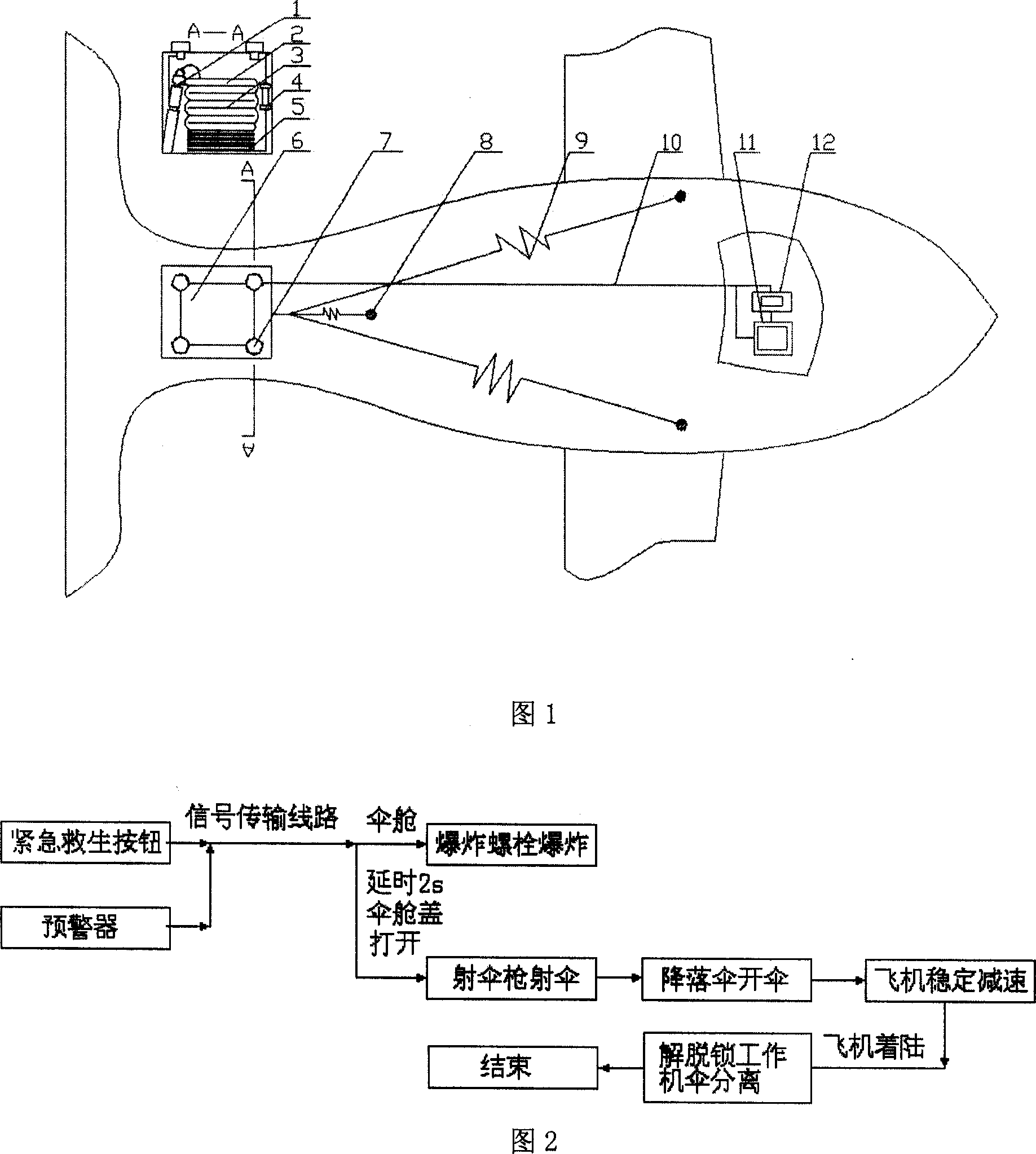

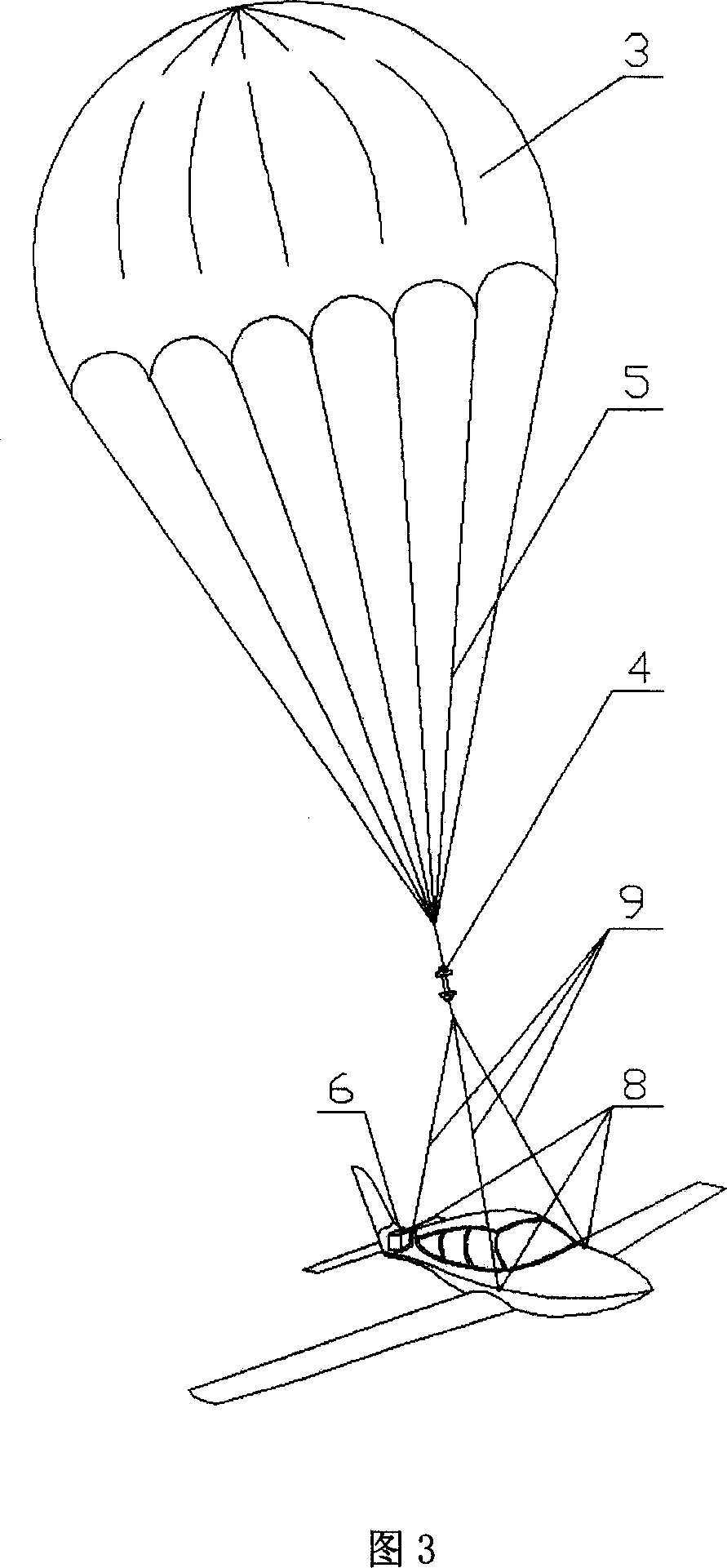

Light airplane safe life-saving system

The invention relates to a safety rescue system of light plane, wherein it comprises injection gun (1), parachute sheath (2), parachute (3), un-locker (4), parachute line (5), explosive bolt (7), suspension ring (8), suspension band (9), signal line (10), alarm (11), and emergency rescue button (12). The invention is characterized in that: the tail of plane has parachute chamber (6) with parachute and injection gun; the parachute line is connected to the suspension band on the plane skin via un-locker. When in emergency, the alarm of chamber and the emergency rescue button work, via the signal line to explode the explosive bolt of chamber door, to open the parachute chamber cover, and the injection gun ejects the parachute (3); then the parachute opens, the plane can reduce speed and land safely; then the un-locker separates the plane and parachute. The invention has simple structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

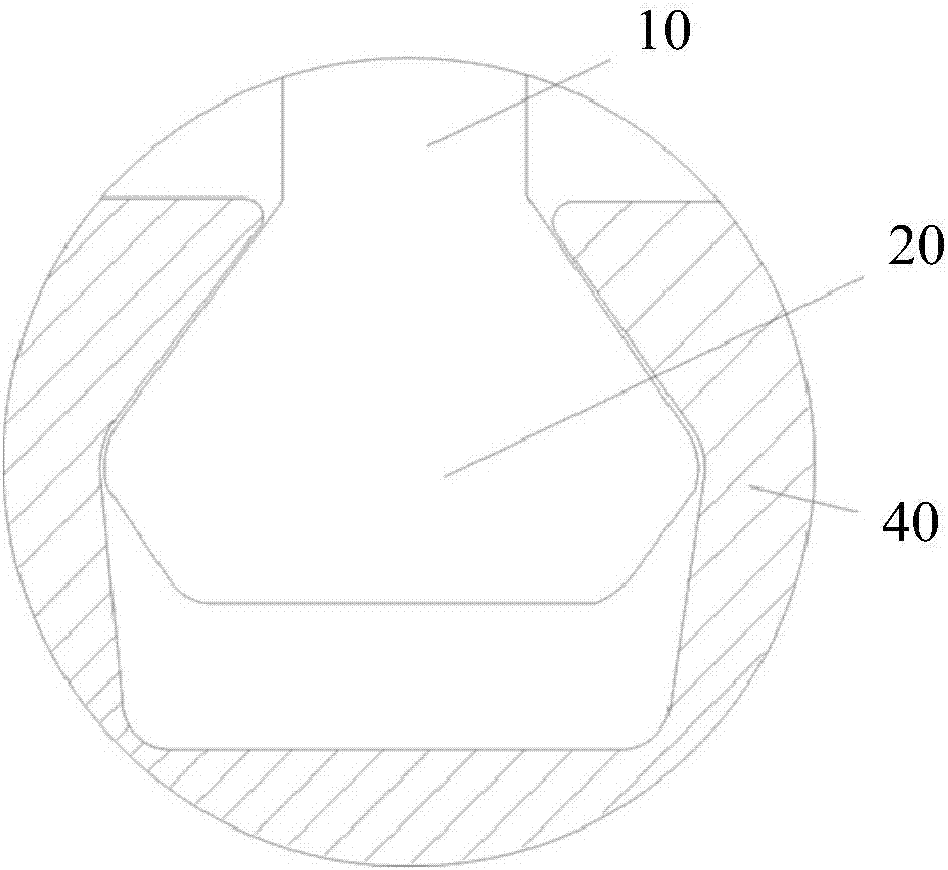

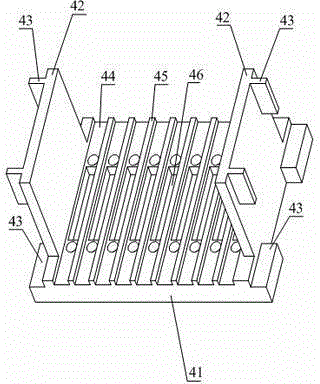

Explosive bolt buffering device

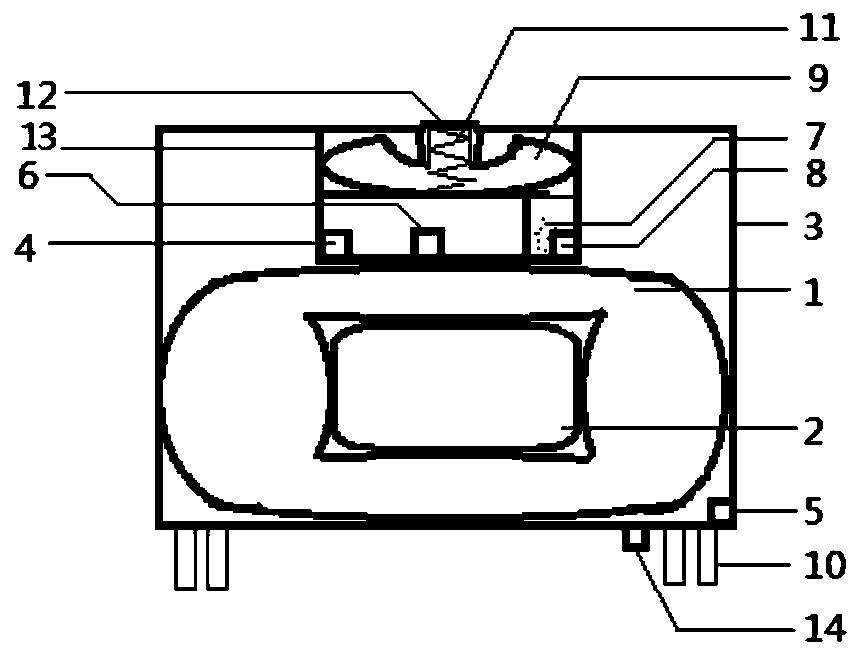

ActiveCN108033038ASimple structureCompact structureCosmonautic vehiclesCosmonautic component separationAviationModularity

The invention relates to the technical field of aerospace, in particular to an explosive bolt buffering device which comprises an installation base, a protection shell cover and an axial buffering device. An installation groove for installing an explosive bolt and the axial buffering device is formed in the installation base. A through hole for the explosive bolt to pass through is formed in the installation base. The protection shell cover is fixedly arranged on the installation base and can cover a groove opening of the installation groove, and the protection shell cover and the installationbase form a closed space together. The axial buffering device is arranged in the closed space. The effective buffering effect on instant large-impact loads is achieved, and the impact degree of the explosive bolt on an upper-stage cabin section in the stage separation test using process is remarkably reduced; the explosive bolt buffering device has the advantages of being small in part number, simple in structure, good in machining process, low in cost, convenient to install, compact in structure, light in weight, high in reliability, good in modularization compatibility and suitable for various aircrafts.

Owner:BEIHANG UNIV

Missile hanger separation mechanism

ActiveCN105066796AImprove space occupancyEasy to install and maintainSelf-propelled projectilesCombustionActuator

The invention discloses a missile hanger separation mechanism. The missile hanger separation mechanism comprises a hanger, an explosive bolt, an actuator, a missile body and a location pin, wherein one end of the actuator is connected with the missile body through a second fastener, and the other end of the actuator is connected with the hanger through a first fastener; one end of the explosive bolt is connected with the missile body through a fourth fastener, and the other end of the explosive bolt is connected with the hanger through a third fastener; the hanger is fixed on the missile body through the location pin, and the contact surface of the missile body and the hanger is a separation surface; a U-shaped groove is formed in the upper end of the explosive bolt, and the central plane of the U-shaped groove is located on the separation surface; and a push rod and a combustion cavity are arranged on and formed in the actuator, the combustion cavity is filled with gunpowder, and the push rod carries out initial locking through a shear pin. The missile hanger separation mechanism disclosed by the invention is simple and convenient to install and maintain, high in action synchronization of initiating explosive devices, and capable of effectively controlling the posture of the hanger after flying away from the missile body, and guaranteeing no collision of the hanger with the missile body during the process of flying away from the missile body, thus improving the flying safety of a carrying aircraft and a missile.

Owner:JIANGXI HONGDU AVIATION IND GRP

Aircraft black box recovery method and device

ActiveCN110015439ASlow downReduce shockFinal product manufactureAircraft components testingRecovery methodNitrogen

The invention provides an aircraft black box recovery method. A black box is mounted and fixed on an aircraft by explosive bolts, an ignition command of the aircraft is used as the starting timing condition, a timer outputs an explosion signal when the preset time is reached to make a tiny explosive device to explode the explosive bolts, the black box is disengaged from the aircraft, at the same time the timer restarts, and after reaching the preset time, airbags open to decelerate. The invention simultaneously provides an aircraft black box recovery device, which comprises a black box protective shell, the main air bag, the small air bag, an air bag box, the explosive bolts, the timer, a control chip, an igniter, nitrogen solid ions, and the like. The mode that the black box is disengagedfrom a mother body by timing explosion of the explosive bolts and lands through the air bags is adopted, and the problems of limited recovery method and poor recovery effect of the black box in the current aircraft development process can be solved.

Owner:ZHONGBEI UNIV

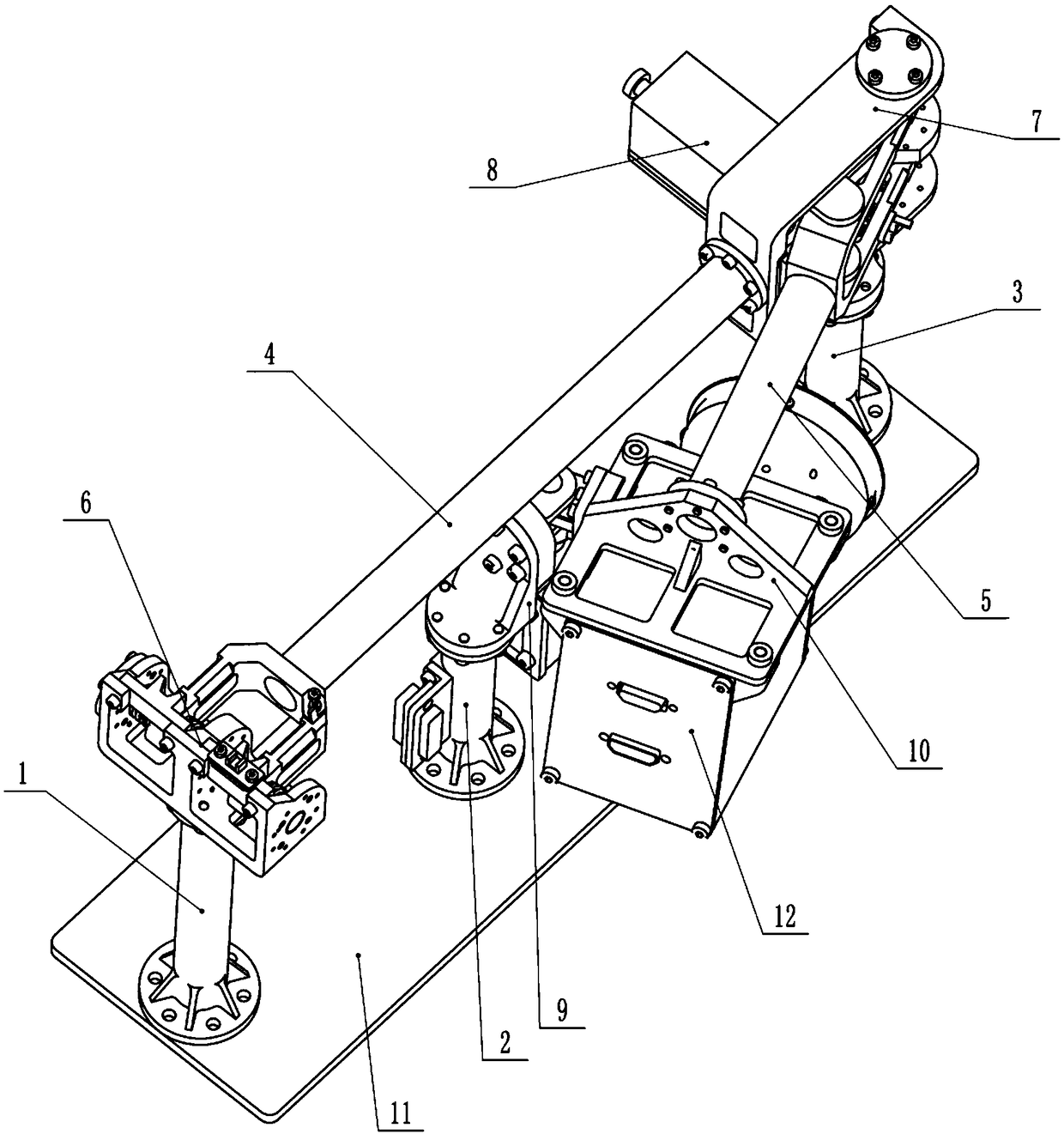

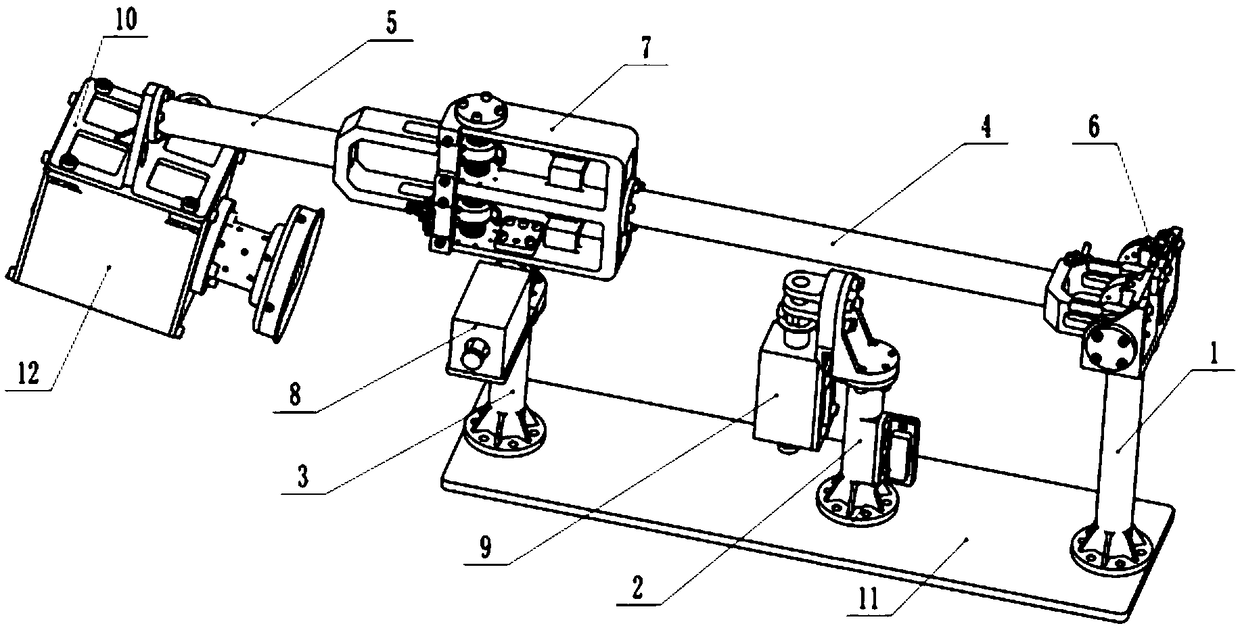

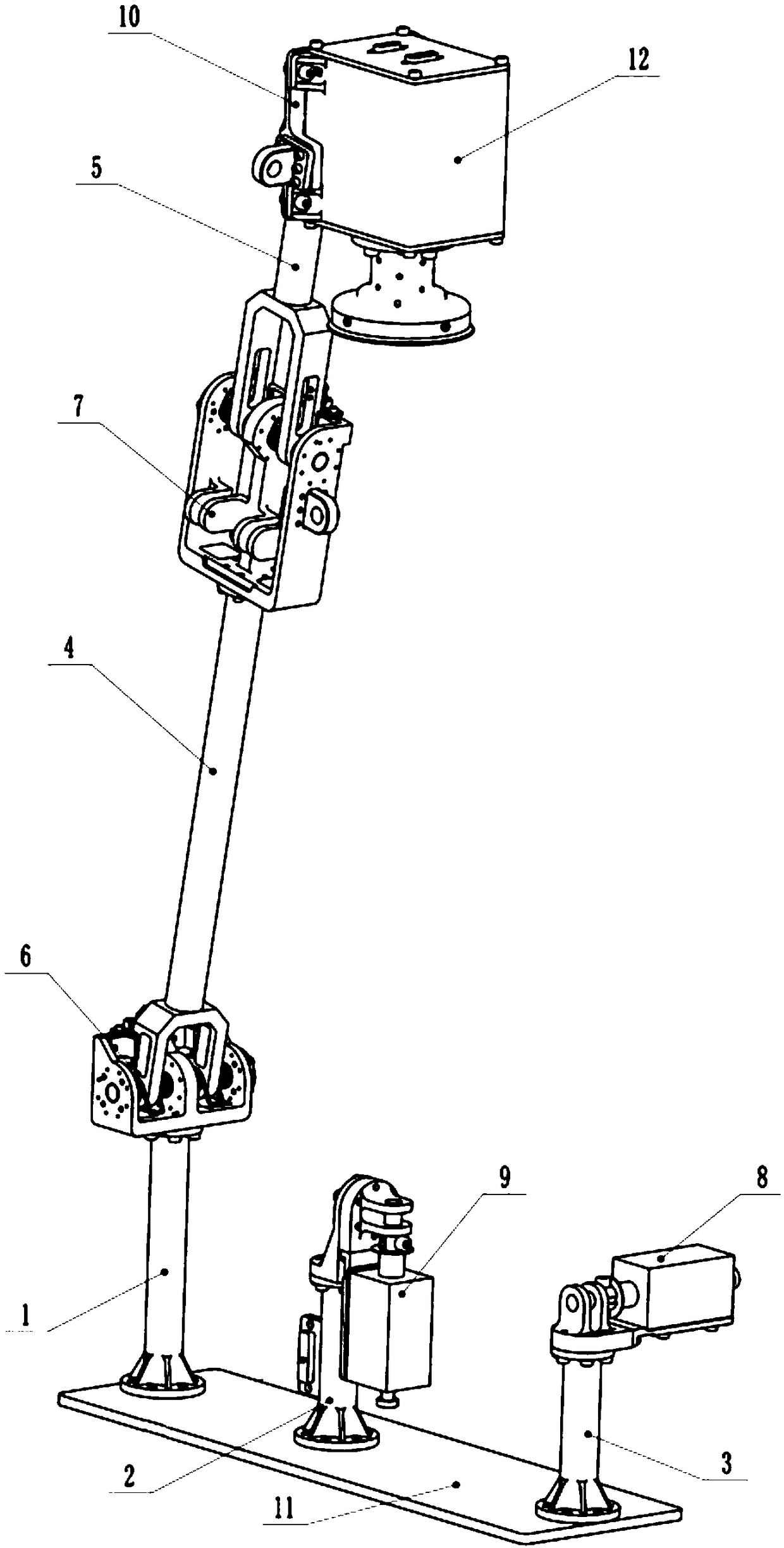

Falling off test rotor assembly and releasing method for the same

ActiveCN107202681ALower flyaway attitudeReduce the impact of flyaway kinetic energyMachine part testingEngineeringMechanical engineering

The invention provides a falling off test rotor assembly and a releasing method for the same. The releasing method comprises steps of separating a connection structure of the rotor assembly which needs to be released from the rotor assembly, using a remaining part of the rotor assembly as a rotor flying-off part, using explosive bolts to connect the rotor flying-off part and the connection structure, detonating explosives built in the explosive bolts under a regulated rotation speed of the rotor in the process of the falling off test, and destroying a bearing capacity of the explosive bolts in order to release the flying-off part of the rotor of the rotor assembly which is connected. The falling off test rotor assembly and the releasing method for the same can effectively improve releasing rotation speed control accuracy, reduce influence on the flying-off posture and flying-off kinetic energy of the rotor assembly, improve convenience and reliability of installation of the releasing device and can reduce the danger in the whole testing process.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Automatically expandable autodyne support for outer space

PendingCN109253358ASimple structureReduce volumeNon-mechanical controlsStands/trestlesElectromagnetic lockLocking mechanism

The invention discloses an automatically expandable autodyne support for the outer space. The automatically expandable autodyne support for the outer space comprises a fixing device, an electromagnetic locking device and an automatic expanding device, wherein the fixing device comprises a fixing seat, a first fixing rod, a second fixing rod and a third fixing rod; the first fixing rod, the secondfixing rod and the third fixing rod are successively perpendicularly arranged on the fixing seat; the automatic expanding device comprises a first joint, a first movable rod, a second joint, a secondmovable rod and a camera mounting seat; and torsional springs are separately arranged in the first joint and the second joint. The automatically expandable autodyne support for the outer space uses principles of electromagnetic locking and torsional spring driving, under the condition that the electromagnetic locking device is energized and unlocked, the autodyne support is automatically expandedunder the driving effect of the torsional spring, the problem that an existing expanding device driven by a motor is high in cost, large in size and poor in reliability is solved, and meanwhile, the technical problems that an existing locking mechanism using initiator explosive bolts for the outer space is high in cost, and the safety and reliability of an aircraft are affected are also solved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Expandable foreign object penetration limiting device

ActiveCN109131957APrevent looseningLimited penetration depthCosmonautic componentsCelestial bodyForeign object

The invention discloses an expandable foreign object penetration limiting device, which comprises six collapsible and expandable limiting units uniformly distributed on a separating barrel of an impactor, one separating barrel and 12 tightening coil springs and 12 explosive bolts outside the barrel. Each limiting monomer comprises a limiting inner plate and a reinforcing rib on the plate, whereina long bar key is arranged on the short side surface of the reinforcing rib; the arc radian of the inner plate of the limiting plate is the same as that of the separating barrel. In the undeployed state, the limiting plate and the separating barrel are seamlessly attached and fastened with explosive bolts to a certain extent, and the end of the limiting plate and the separating barrel are hinged with coil springs. When unfolding, the explosive bolt is broken, the key is embedded in the keyway of the separation barrel, and the coil spring is still in a tensioned state, so that the self-lockingdevice is realized when unfolding. The device can withstand the impact of the impact, and can effectively achieve the separation section staying on the surface of the celestial body, playing the function of penetration limit.

Owner:SHANGHAI SATELLITE ENG INST

Ammunition-parachute separation rotating device of parachute used for ammunition

Owner:XIANGYANG HONGWEI AIRCRAFT

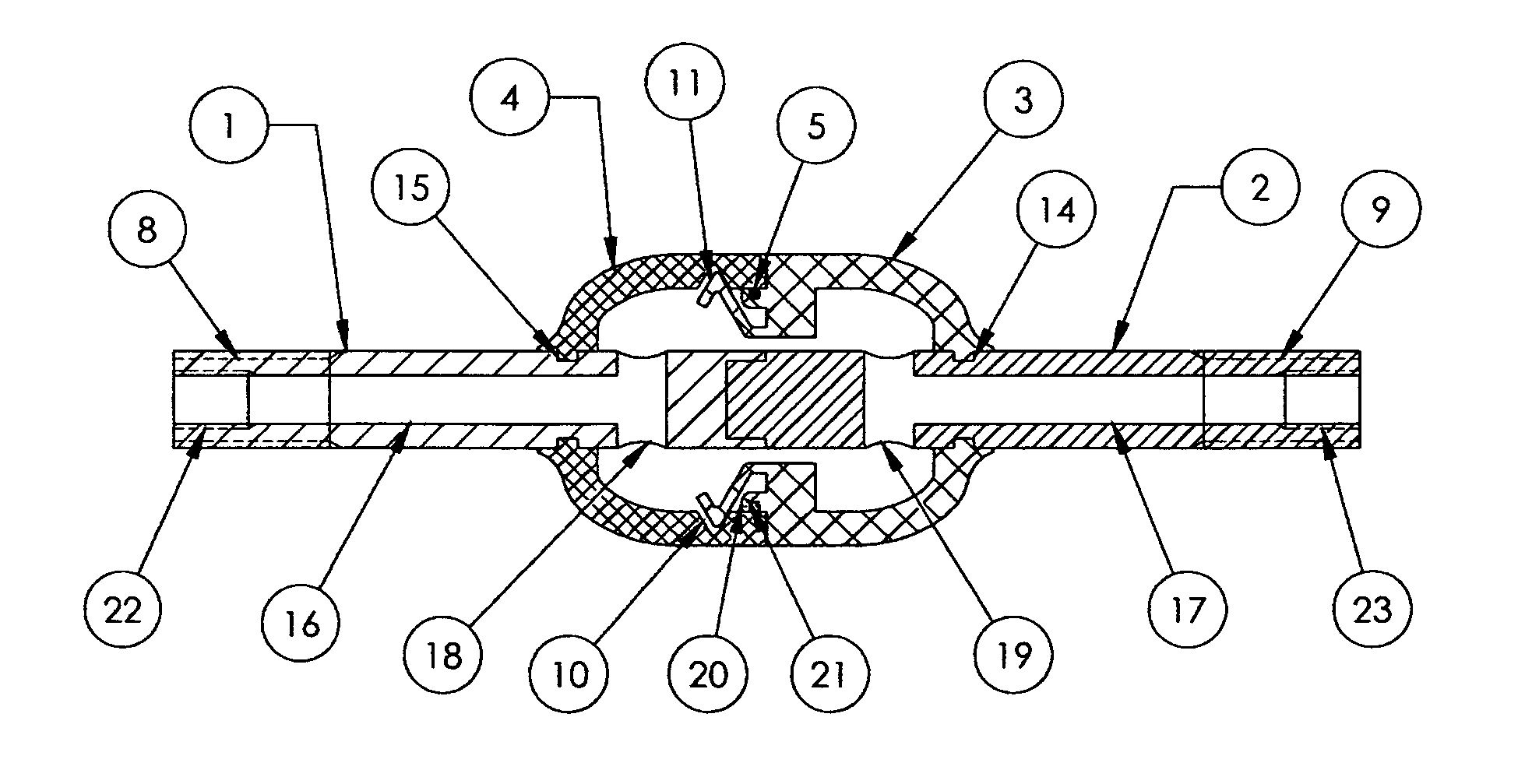

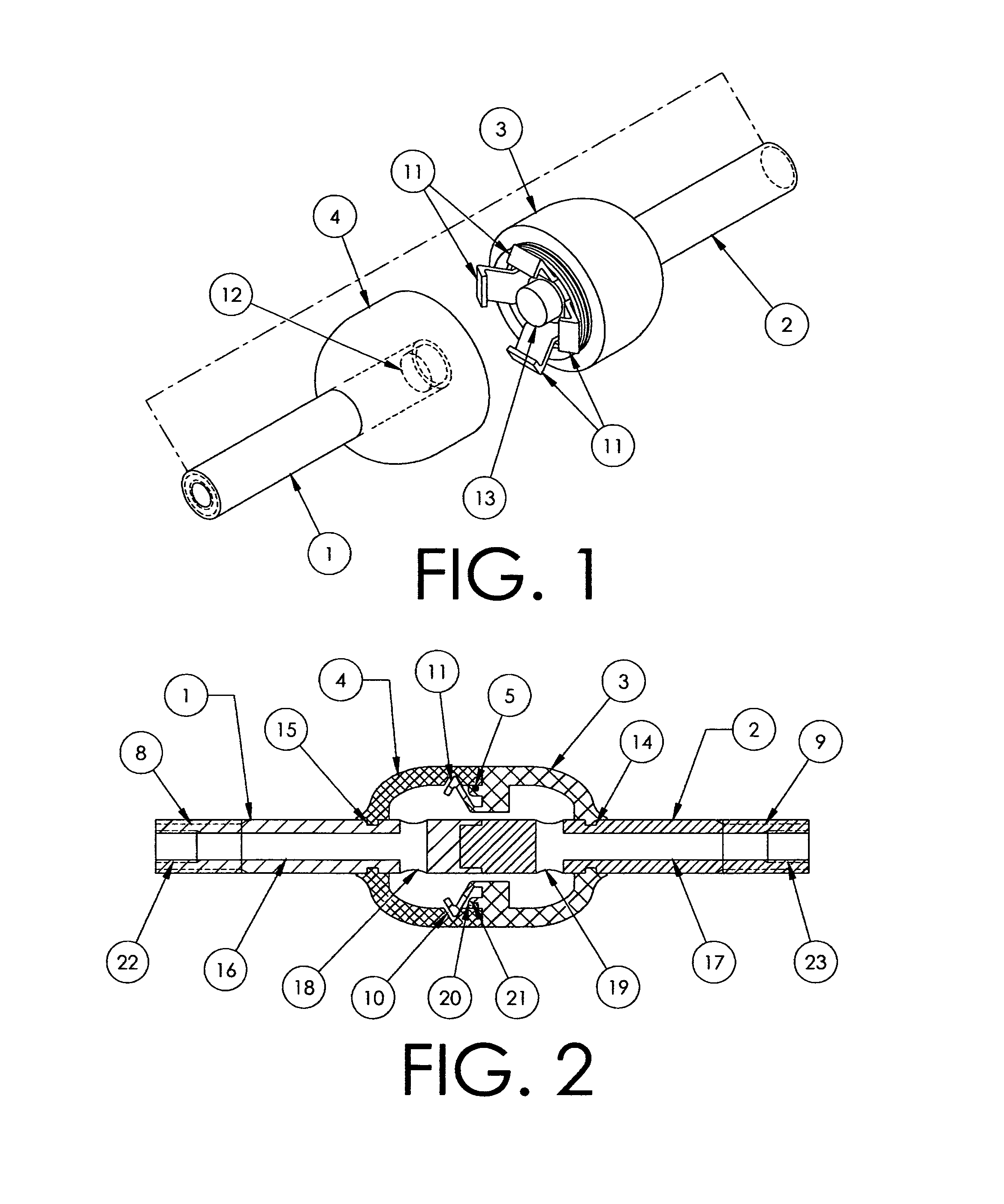

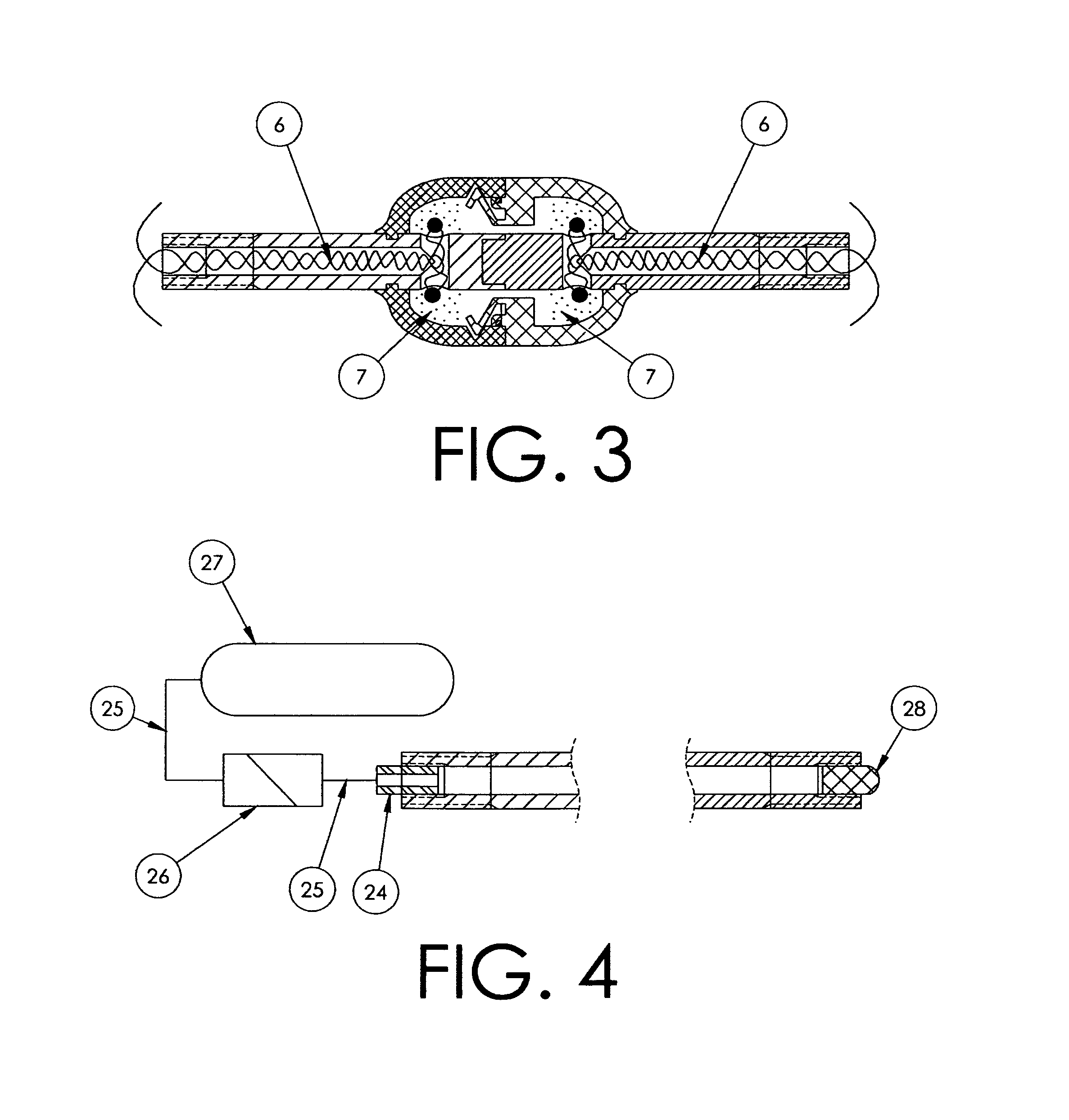

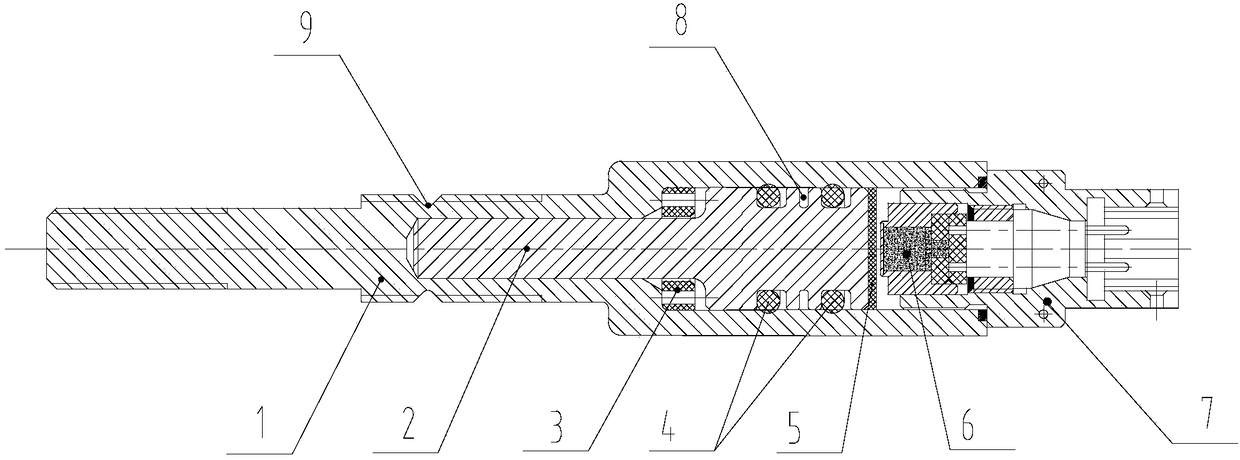

Reusable Explosive Bolt

InactiveUS20110200384A1Safe separationSafe releaseCosmonautic vehiclesFluid pressure sealed jointsSolenoid valveEngineering

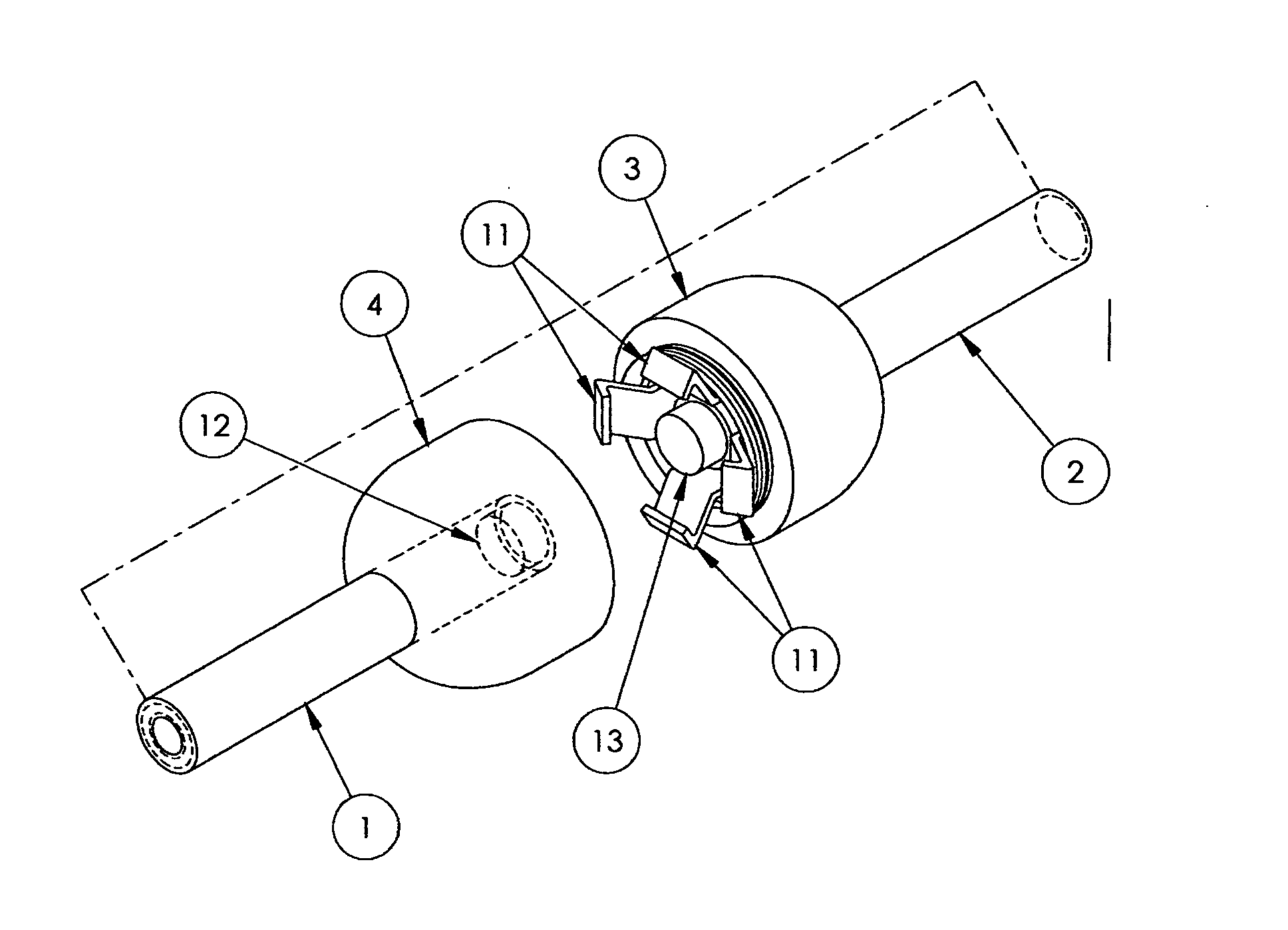

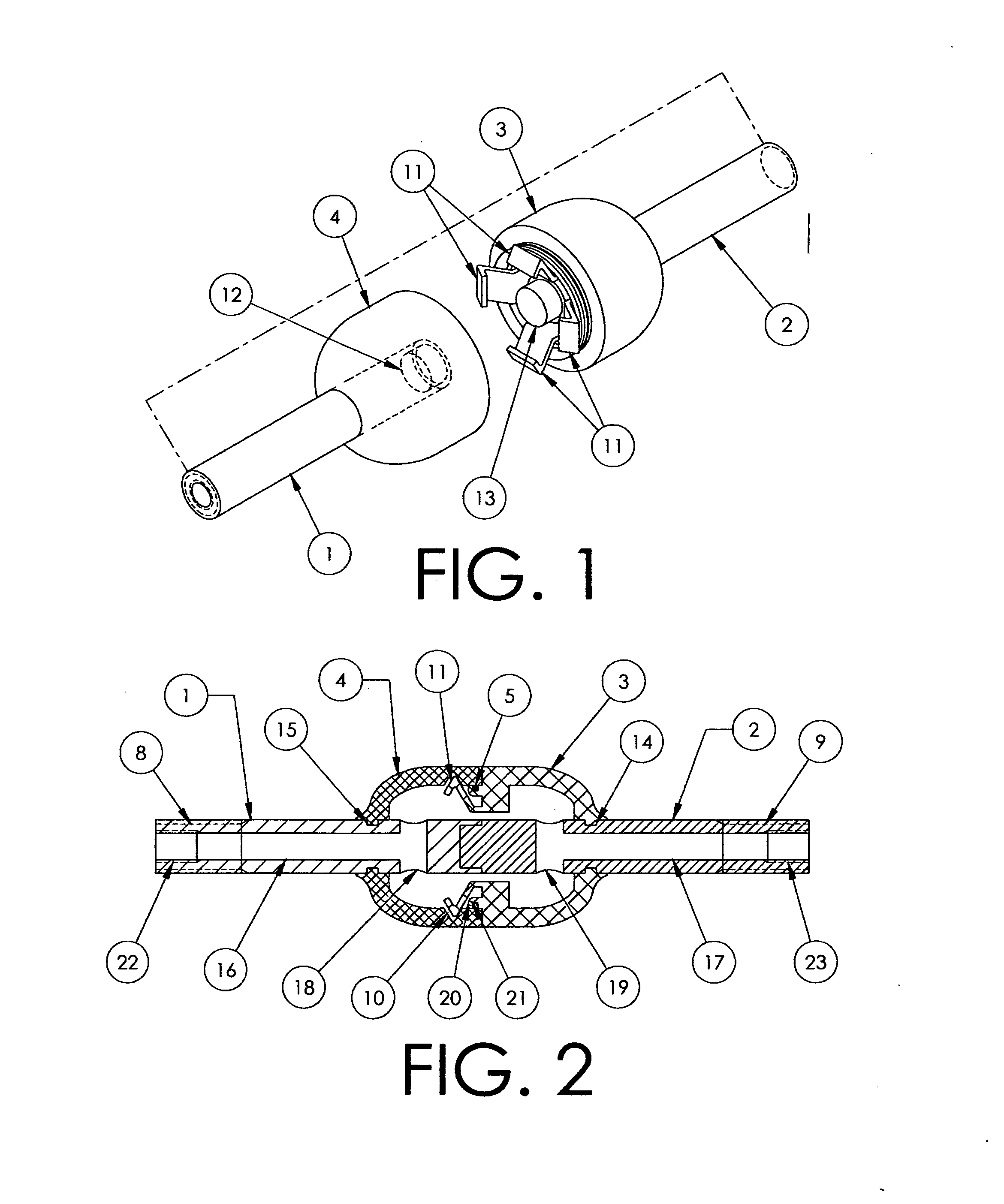

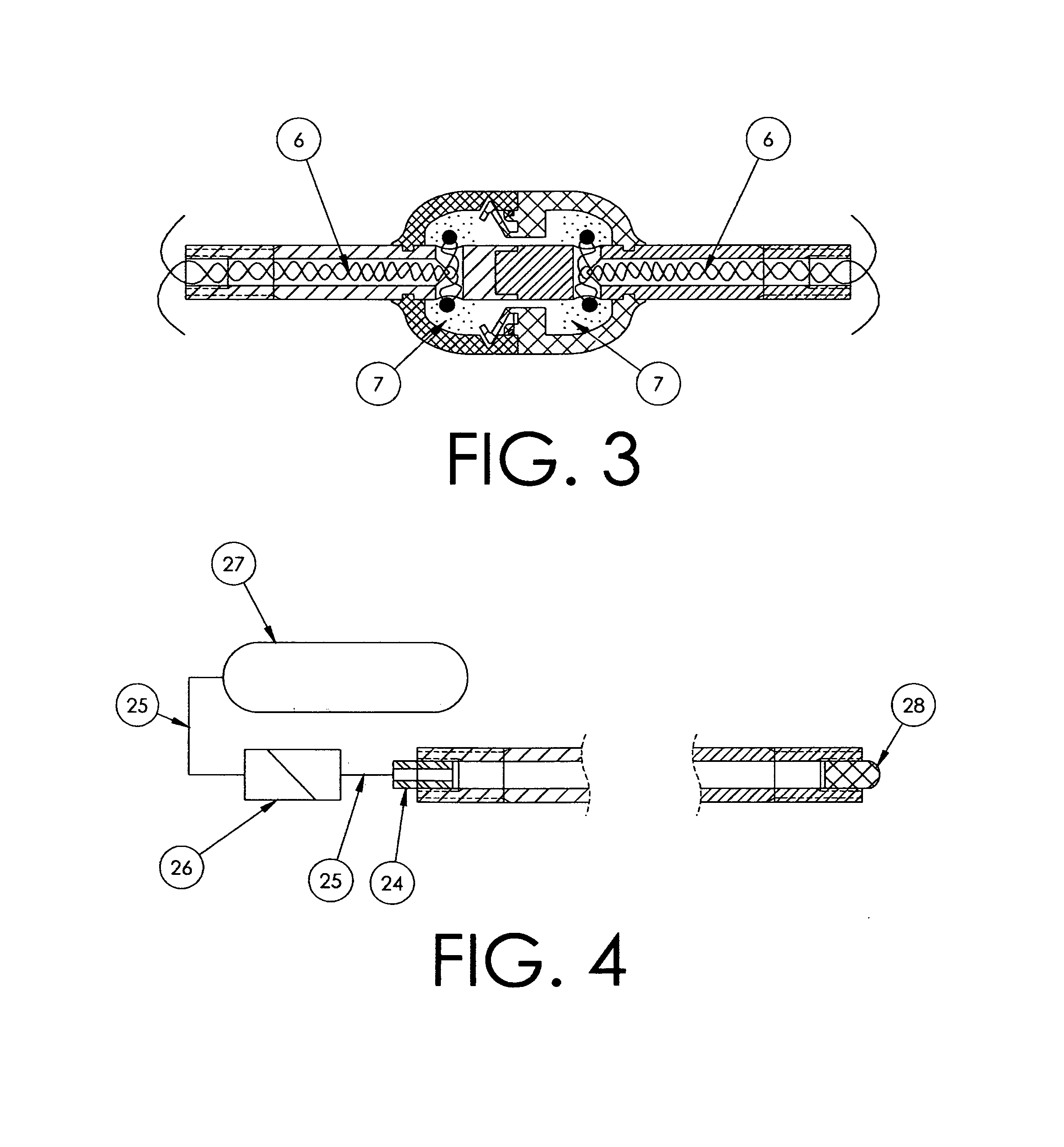

An axial loaded explosive bolt that can repeatedly be used for the purpose of remotely or automatically activating a timely separation of adjoining walls separated by a finite distance by the means of either an explosive charge or activation of a pressurized gas line. The fastener includes two bolts with internal bores that are attached by the means of a two-piece encapsulation connected by an inter-connecting clasp. The fastener assembly employs the use of either a combination of a thermal igniter and a pyrotechnic charge or a pressurized gas line attached to a solenoid valve and pressurized gas storage unit to supply a force sufficient to properly separate the said mechanical fastener assembly.

Owner:TERRY BRANDON

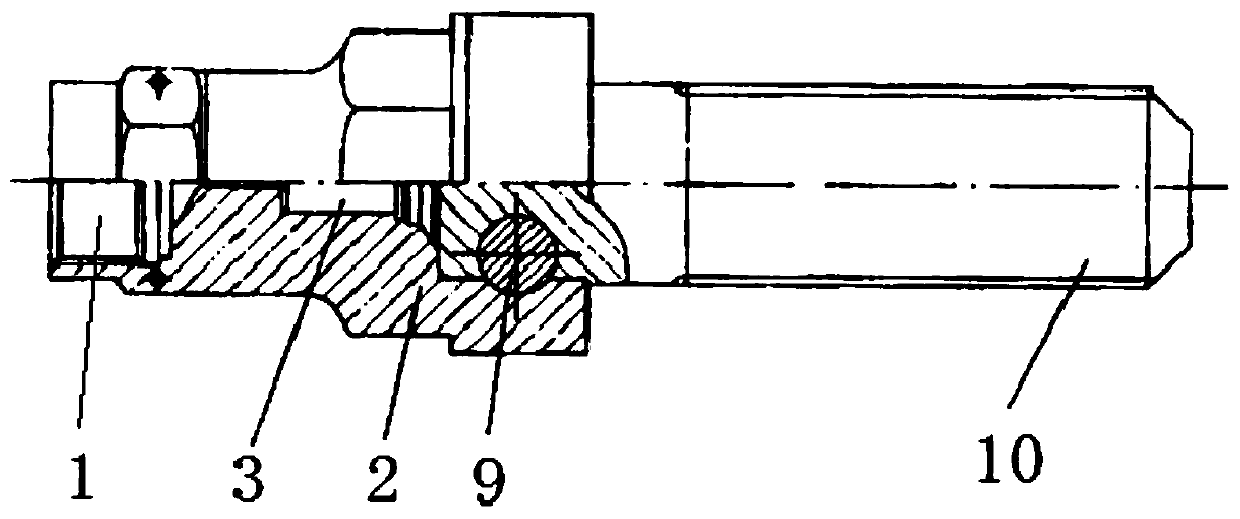

Cargo-parachute separation mechanism after airdrop device entering water

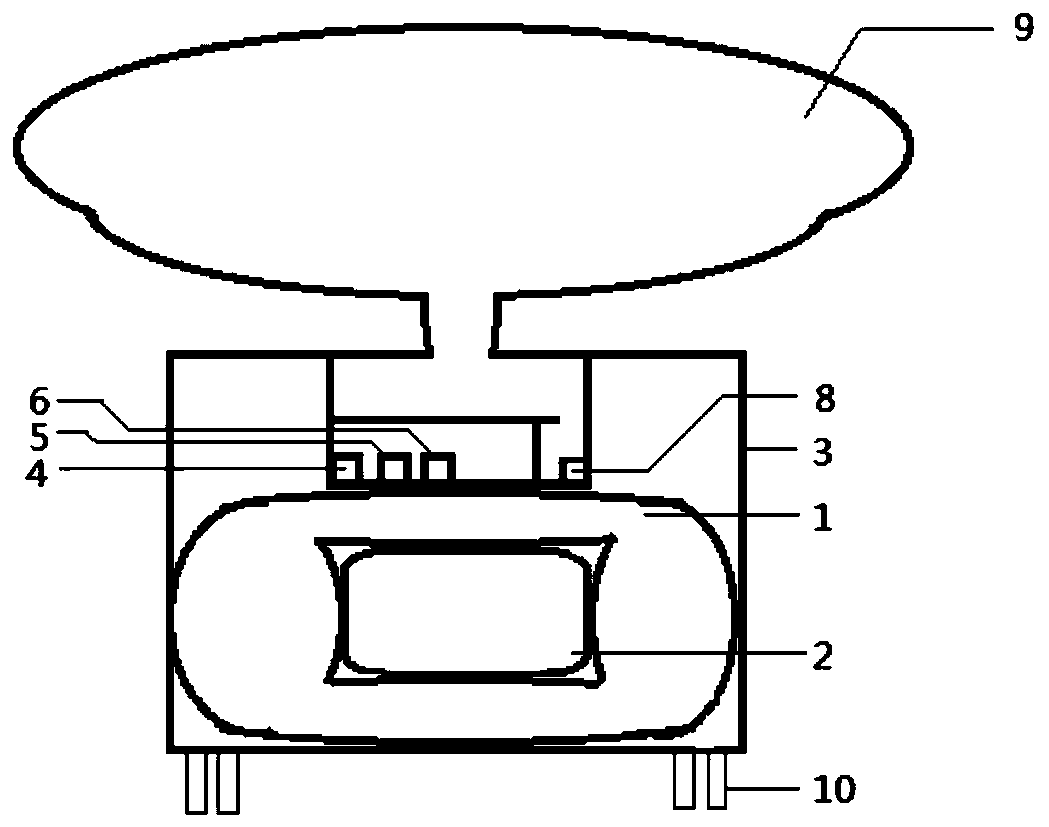

PendingCN109398653AImprove reliabilityEasy to separateParachutesUnderwater equipmentElectricityEngineering

The invention discloses a cargo-parachute separation mechanism after an airdrop device entering water, and solves the problems of slow separation speed and low separation success rate in a prior separation mechanism. A spring (1) is arranged between a piston (13) and a barrel cover (11), a thermal battery start pin sleeve (16) is arranged in a piston barrel (10) below the piston (13), and a compressed compression spring (18) is arranged on the thermal battery start pin (6), a safety pin (2) is fixed on the bottom surface of the piston (13), the thermal battery (3) is arranged in the piston barrel body (10) below the thermal battery start pin sleeve, and an explosive bolt control circuit board (7) is connected with an adiabatic pad (4), an explosion bolt (9) is fixed on the bottom plate ofthe piston barrel body (10), and the explosion bolt is electrically connected with the explosion bolt control circuit board, and an airdrop device connection seat (5) is fixed on the lower end of theexplosion bolt. The device can be put in place quickly after entering water, and the cargo and the parachute can be separated quickly.

Owner:SHANXI FENXI HEAVY IND

Non-pyrotechnic separation device based on explosive bolt

PendingCN109737831ARealize separation and unlockingLow costSelf-propelled projectilesGas cylinderEngineering

The invention relates to the technical field of aerospace equipment, in particular to a non-pyrotechnic separation device based on an explosive bolt. The non-pyrotechnic separation device comprises atleast one explosive bolt and at least one high-pressure gas cylinder, wherein a gas chamber for accommodating a high-pressure gas is arranged in the explosive bolt; and the high-pressure gas cylinderis communicated with the gas chamber of the explosive bolt through at least one pipeline, is used for conveying the high-pressure gas stored in the high-pressure gas cylinder to the gas chamber of the explosive bolt through the pipeline, and applies an acting force to the explosive bolt to divide the explosive bolt. The non-pyrotechnic separation device based on the explosive bolt, provided by the invention, is reusable and low in cost and does not generate harmful gases.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

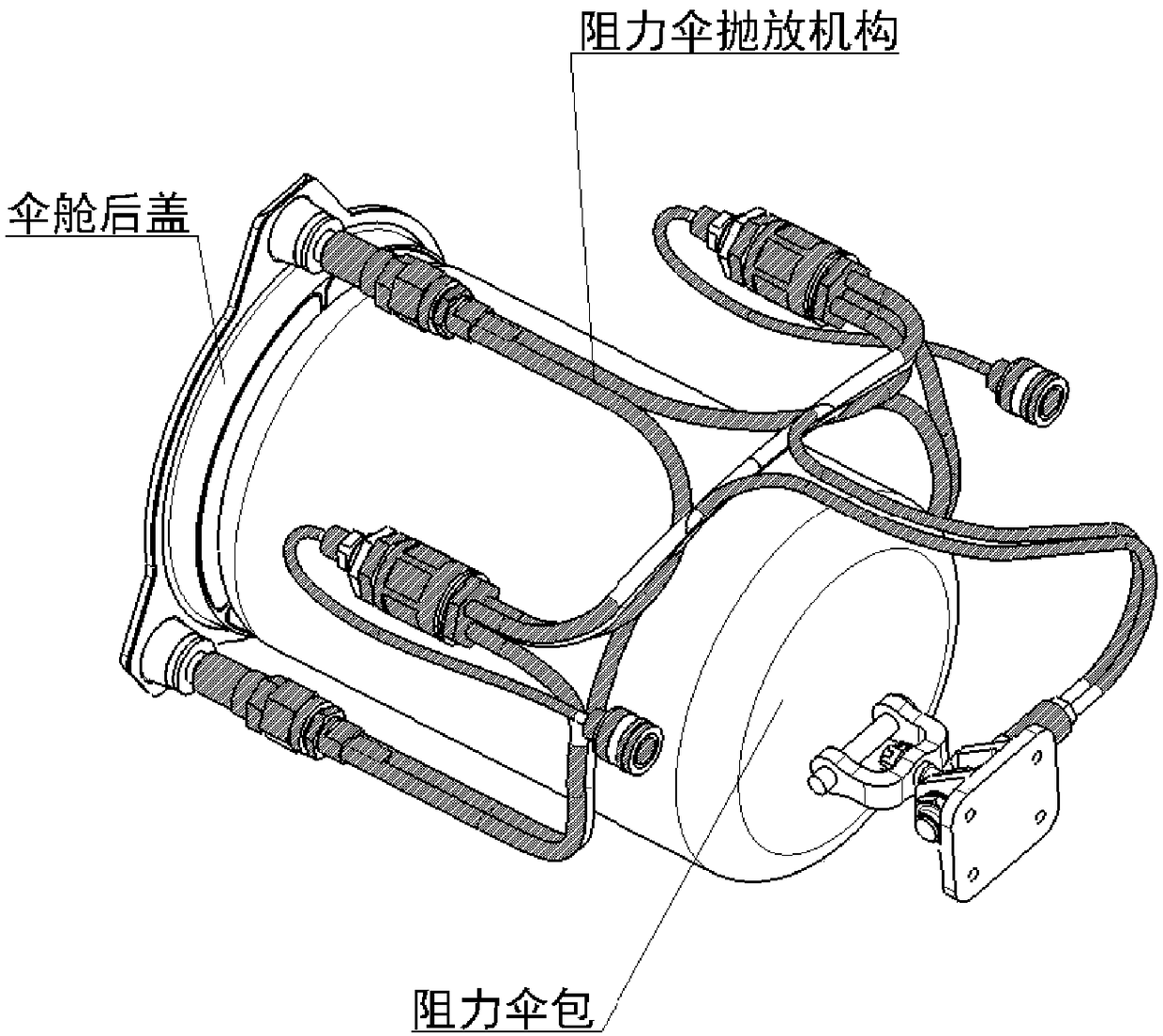

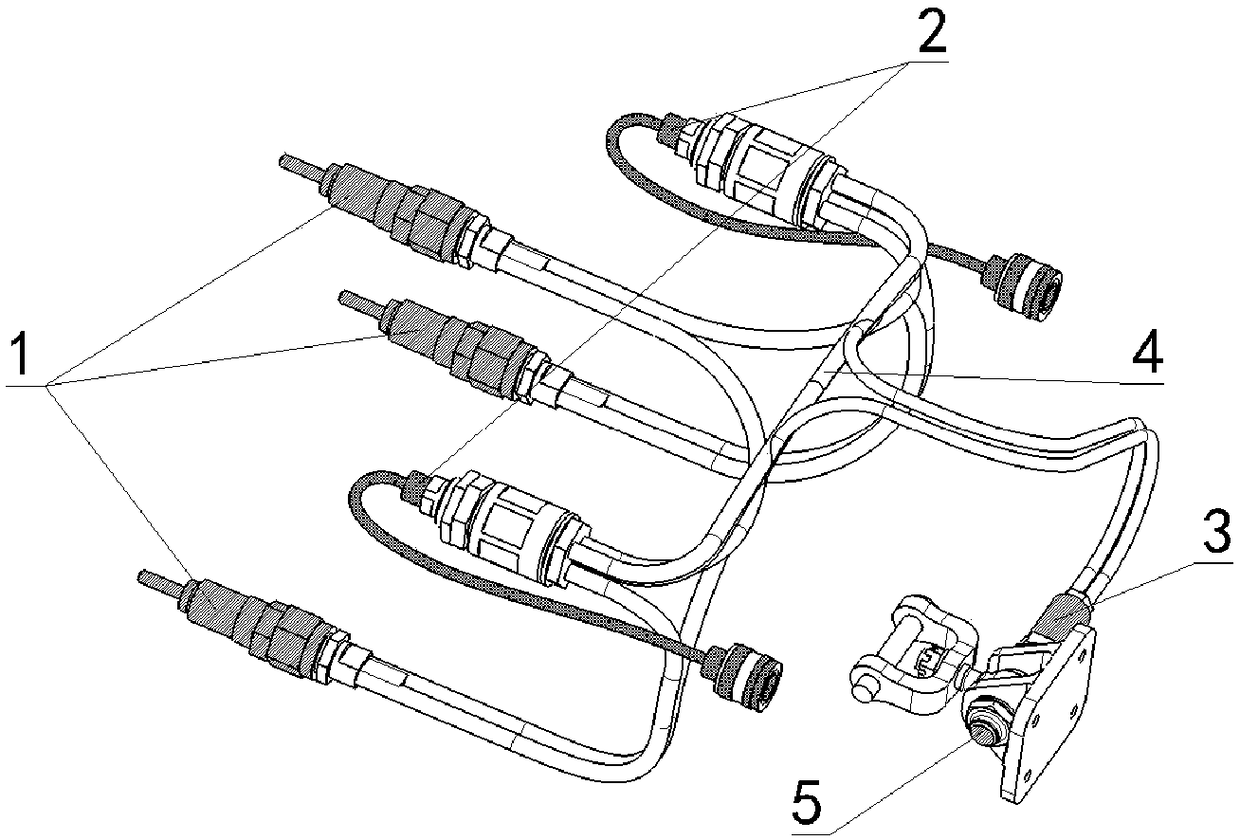

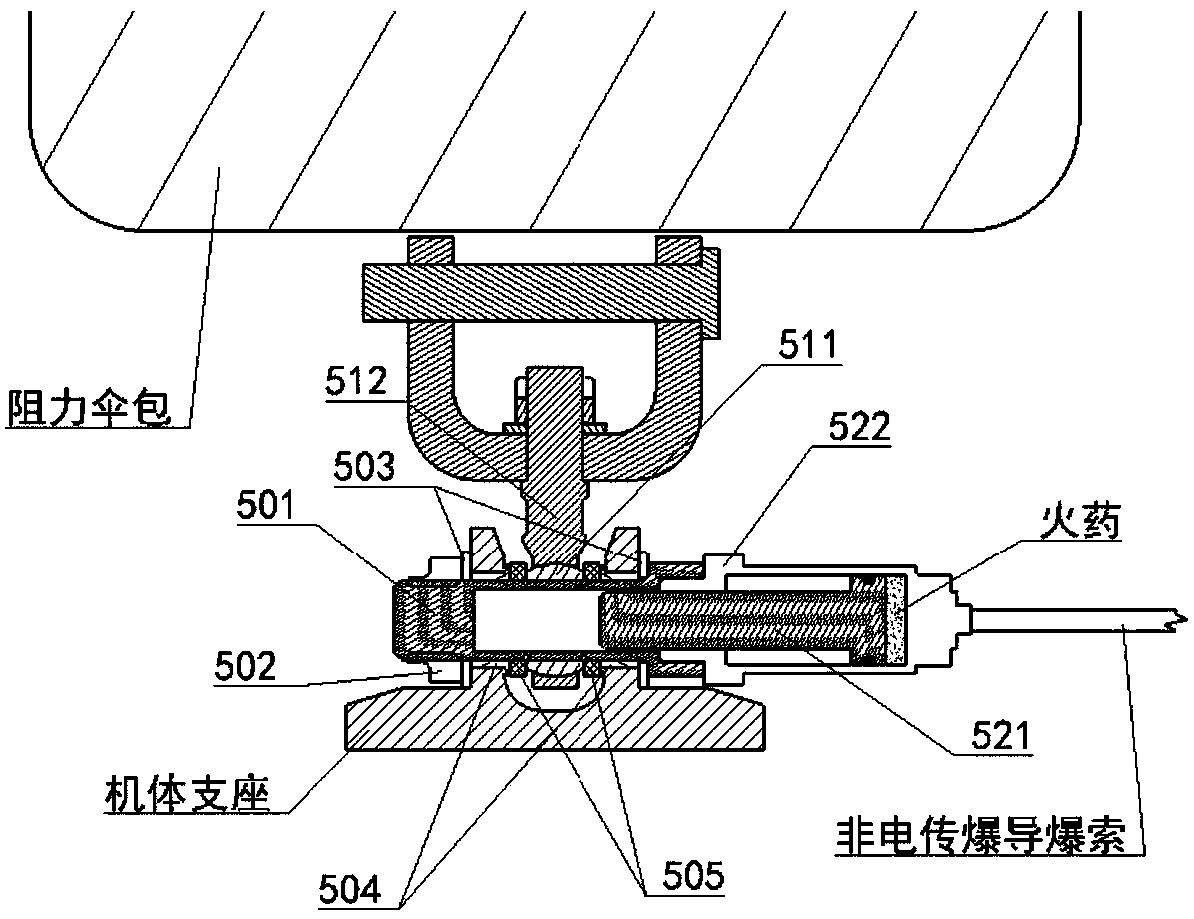

Drag parachute throwing-releasing mechanism with automatic parachute throwing function after failure

ActiveCN108238257AEnsure flight safetyNormal aerodynamic dragAircraft accessoriesParachutesDetonationEngineering

The invention belongs to an aircraft drag parachute system, and particularly discloses a drag parachute throwing-releasing mechanism with an automatic parachute throwing function after failure. The drag parachute throwing-releasing mechanism is composed of explosive bolts, electric exploders, a pin pushing machine, a non-electric-detonation assembly and a false lock device. The explosive bolts areconnected with an airframe mechanism and a drag parachute cabin rear cover, the false lock device is connected with an airframe support and a drag parachute hanging ring, and the pin pushing end of the pin pushing machine is connected with the false lock device through a thread. The output end of the non-electric-detonation assembly is connected with the explosive bolts and the other end of the pin pushing machine, and the input end of the non-electric-detonation assembly is connected with the electric exploders. One parallel ignition circuit is only needed to add in a traditional non-electric-detonation system, and the ''failure-safety'' function can be realized; and a drag parachute cabin sensor and a related logic judgment system are not needed to be added, the system logic is simple,all functions can be realized only by an initiating explosive device system, and the structure space and weight of the sensor and cable installation thereof are saved.

Owner:CHENGDU AIRCRAFT DESIGN INST OF AVIATION IND CORP OF CHINA

Reusable explosive bolt

InactiveUS8171839B2Safe releaseCosmonautic vehiclesFluid pressure sealed jointsSolenoid valveEngineering

An axial loaded explosive bolt that can repeatedly be used for the purpose of remotely or automatically activating a timely separation of adjoining walls separated by a finite distance by the means of either an explosive charge or activation of a pressurized gas line. The fastener includes two bolts with internal bores that are attached by the means of a two-piece encapsulation connected by an inter-connecting clasp. The fastener assembly employs the use of either a combination of a thermal igniter and a pyrotechnic charge or a pressurized gas line attached to a solenoid valve and pressurized gas storage unit to supply a force sufficient to properly separate the said mechanical fastener assembly.

Owner:TERRY BRANDON

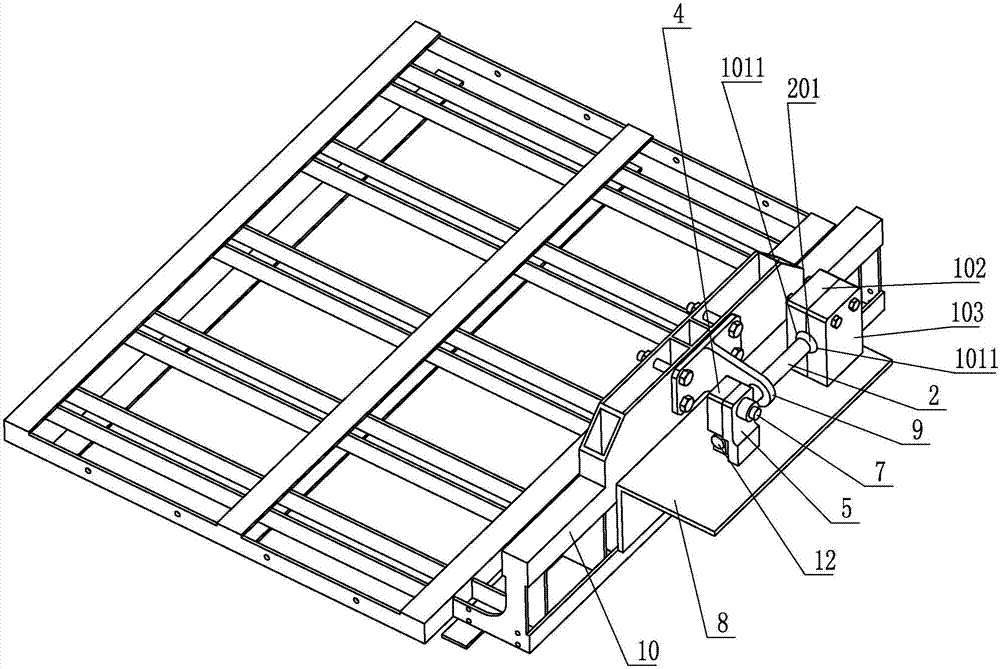

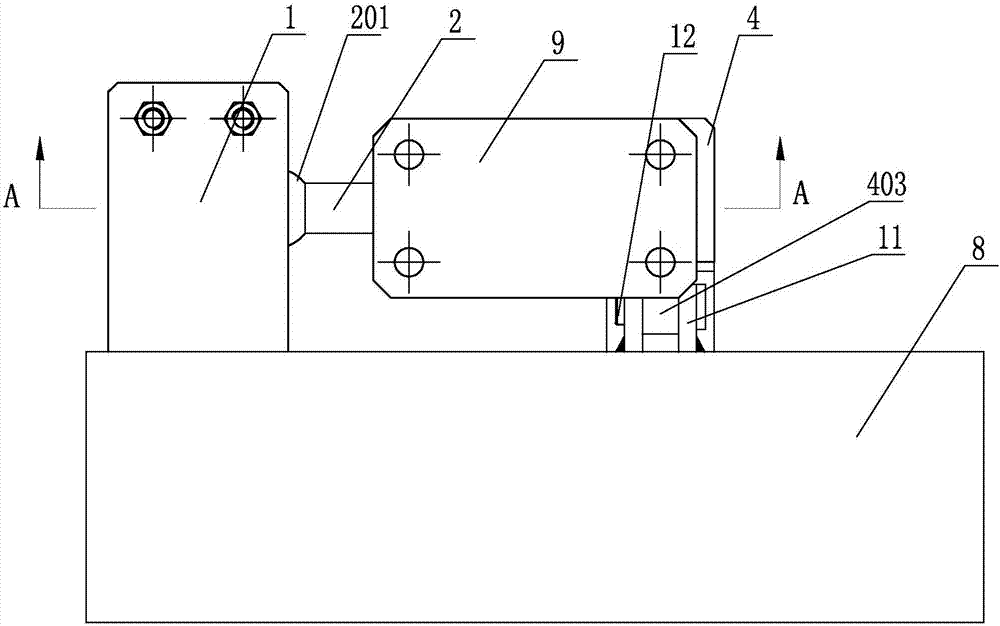

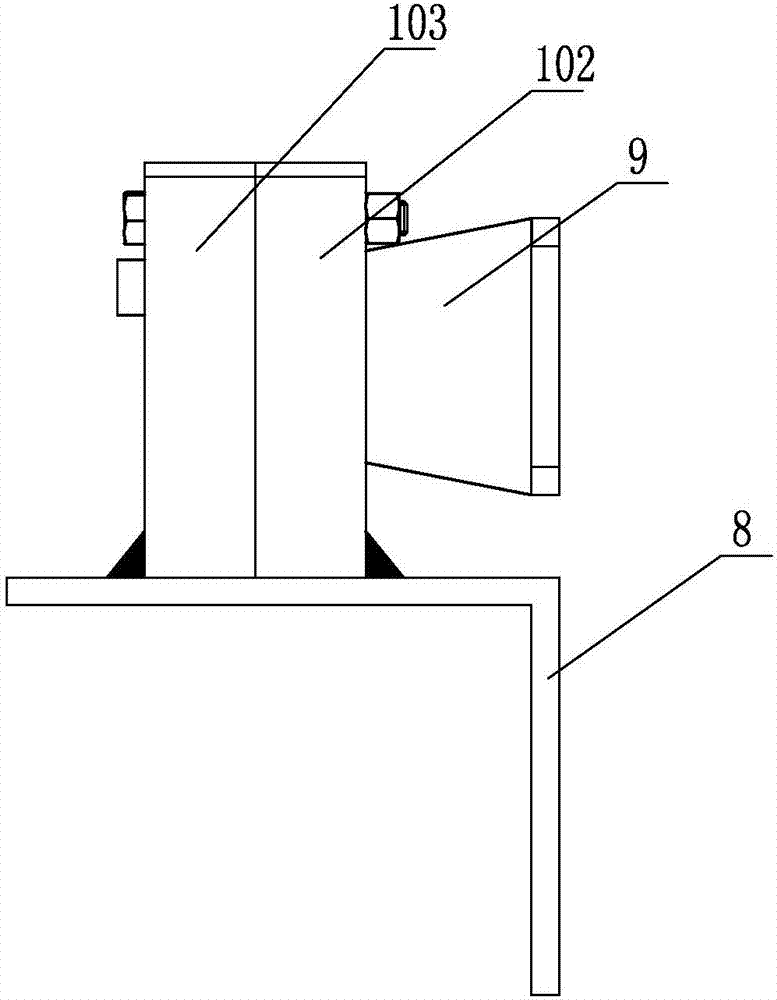

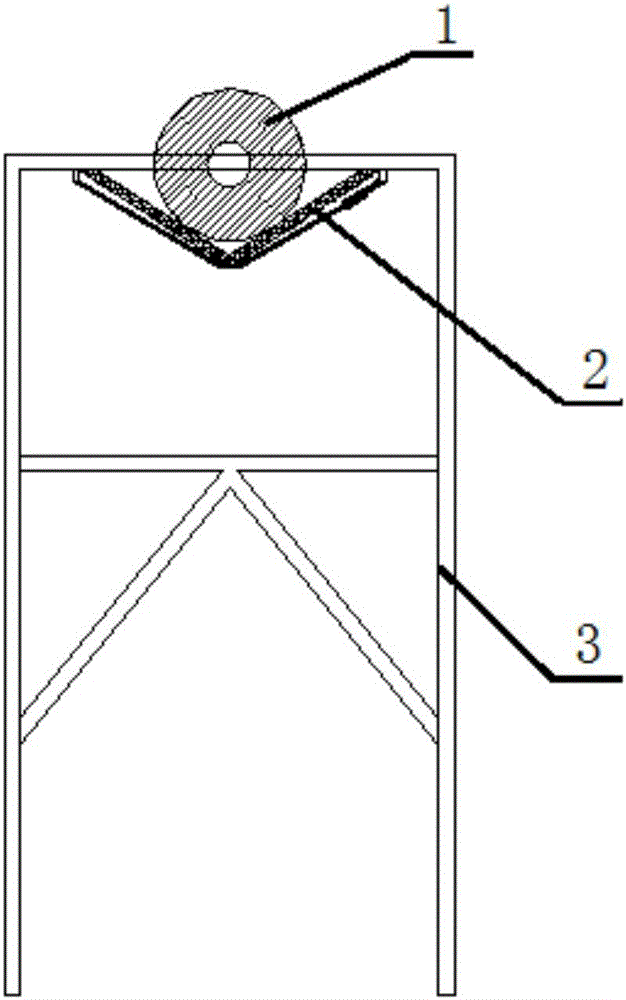

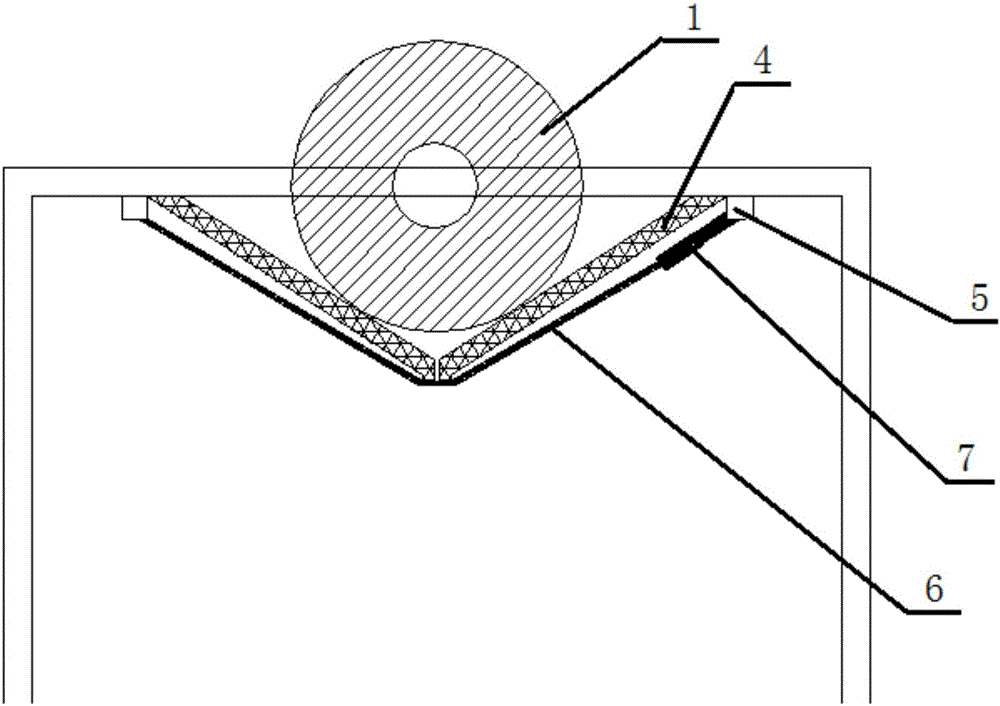

Large scale solid engine drop test release device

The invention discloses a large scale solid engine drop test release device which can be applied to large scale engine drop tests. The large scale solid engine drop test release device is strong in transient response capability and good in movement synchronicity. The device comprises a test rack and a release mechanism, wherein the test rack is used for supporting the release mechanism, an engine being tested can be arranged at a specified height on the release mechanism, the release mechanism supports the engine being tested via a baffle plate in a lifting manner, the baffle plate is fixed with a binding tie, and one of the binding tie is connected via an explosive screw bolt assembly. When a downward explosion screw bolt sends an initiation signal, the explosion screw bolt is broken, the binding tie is loosened, the baffle plate is untied without constraint, and the engine being tested falls freely. The engine being tested is supported in a lifted manner, a phenomenon that the engine is damaged due to clamping force of a clamping tool or calipers can be prevented, and the structure of the device is simpler and smaller than the structure of the clamping tool or the calipers; compared with a conventional clamping force unloading mode, the device which employs the explosion screw bolt is strong in transient response capability and good in movement synchronicity, and testing precision control can be improved.

Owner:XIAN AEROSPACE PROPULSION TECH INST

Buffer structure, buffer energy-absorbing recovery device and aircraft

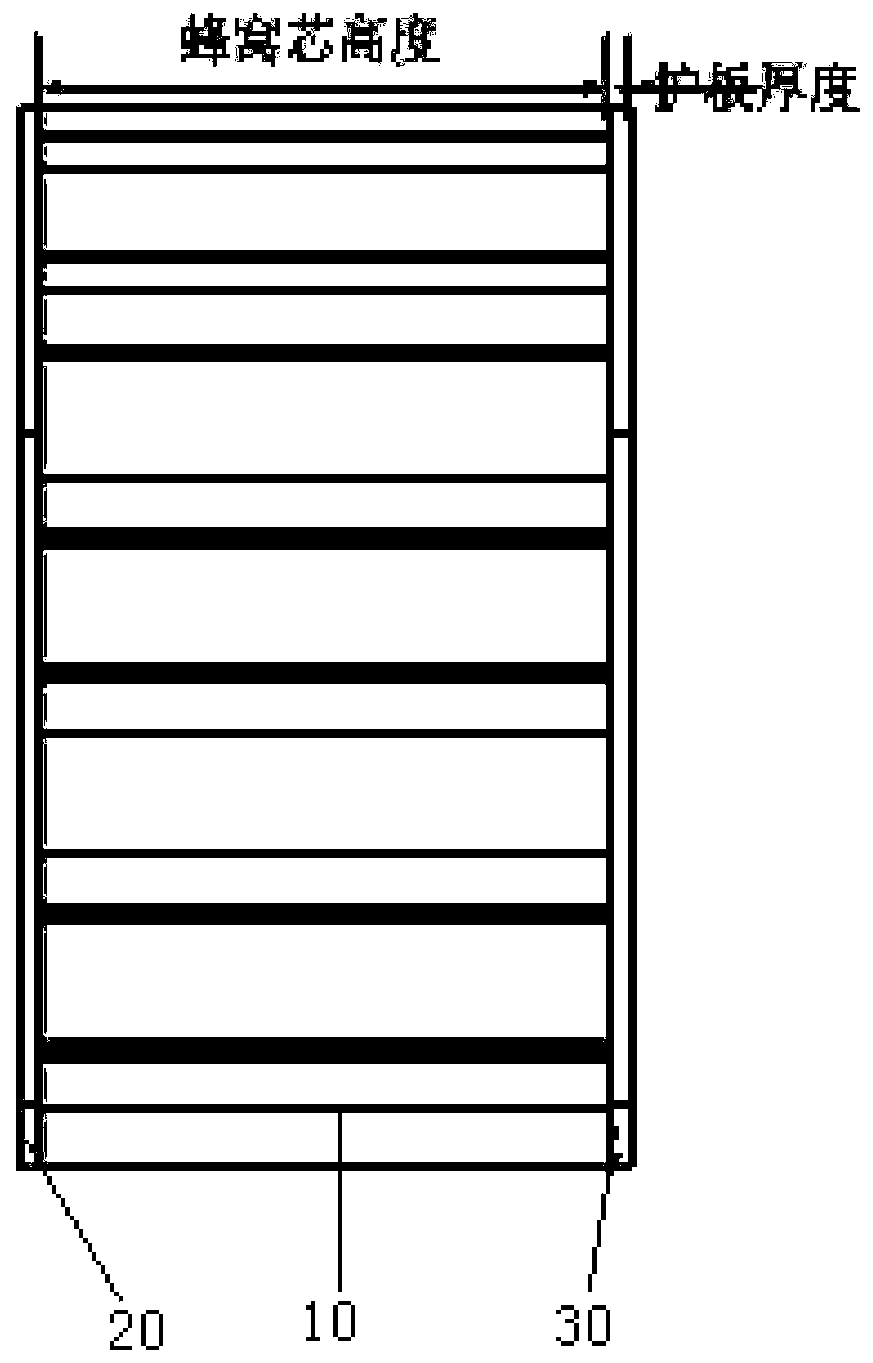

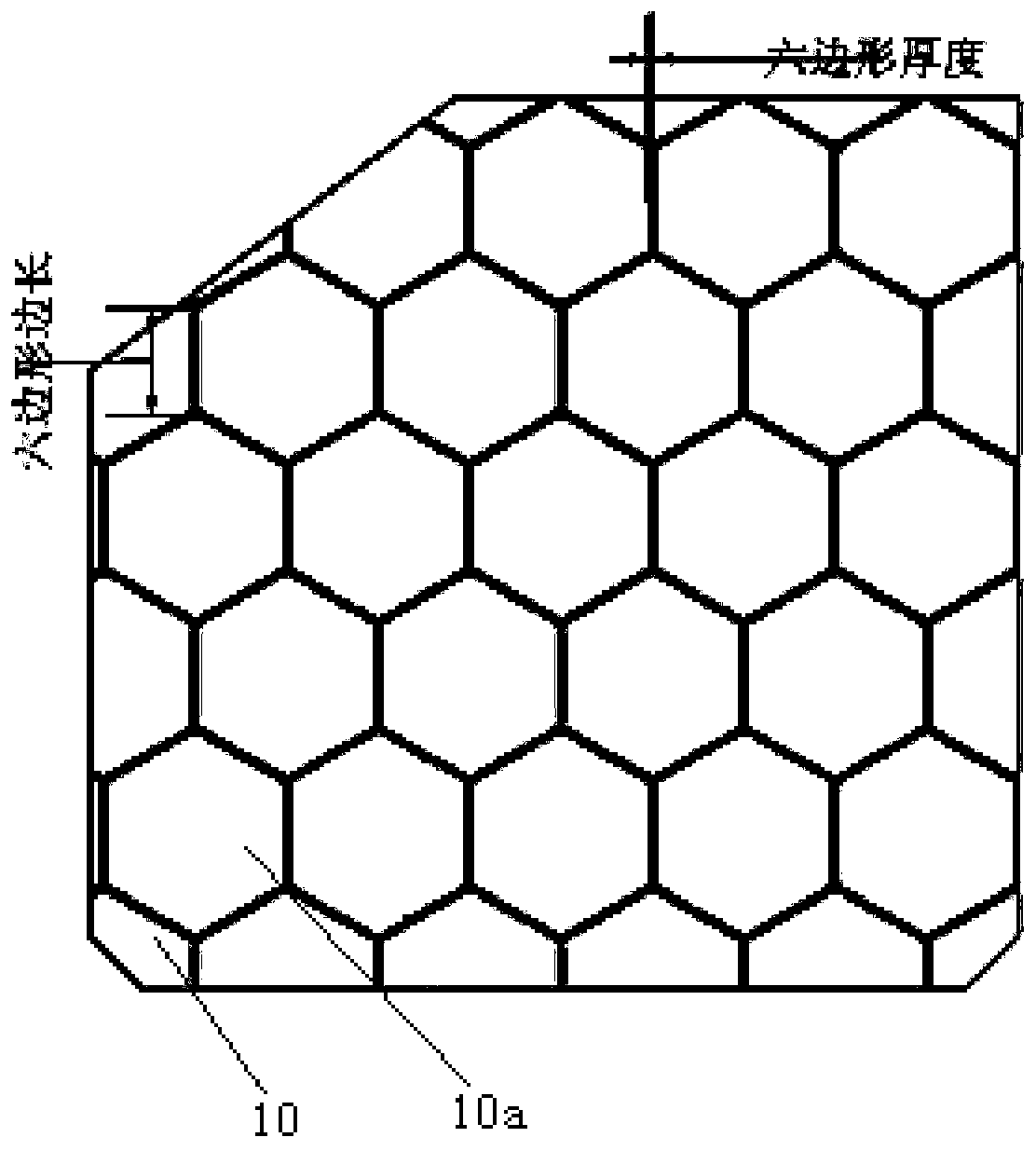

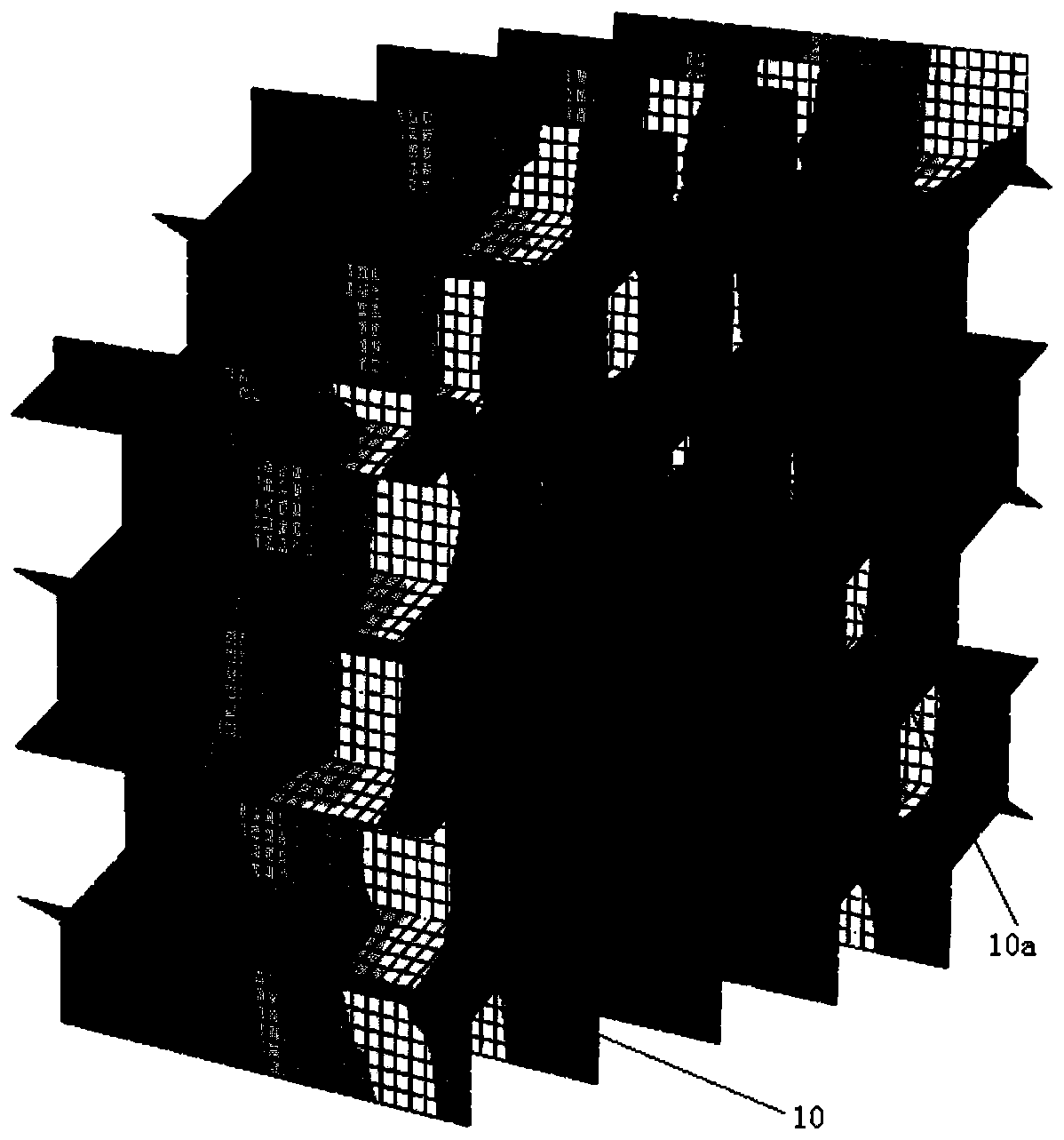

ActiveCN109703731AConstrained springbackProlong the action timeFuselagesAircraft indicatorsHoneycombPyrotechnic fastener

The invention provides a buffer structure, a buffer energy-absorbing recovery device and an aircraft. The buffer structure comprises: a honeycomb core having a plurality of accommodating holes for accommodating residual parts of explosion bolts during the stage separation process of the aircraft, a first panel and a second panel, wherein the honeycomb core is arranged between the first panel and the second panel; cross-sections of the first panel and the second panel and the honeycomb core are designed in shape; and during the stage separation stage of the aircraft, the buffer structure can absorb the energy of the residual parts of the explosion bolts through self moulding and deformation. The technical solution of the buffer structure is applied to solve the technical problem that the prior art cannot safely and reliably recover the separated parts with high hazardness of the explosion bolts.

Owner:BEIJING AEROSPACE TECH INST

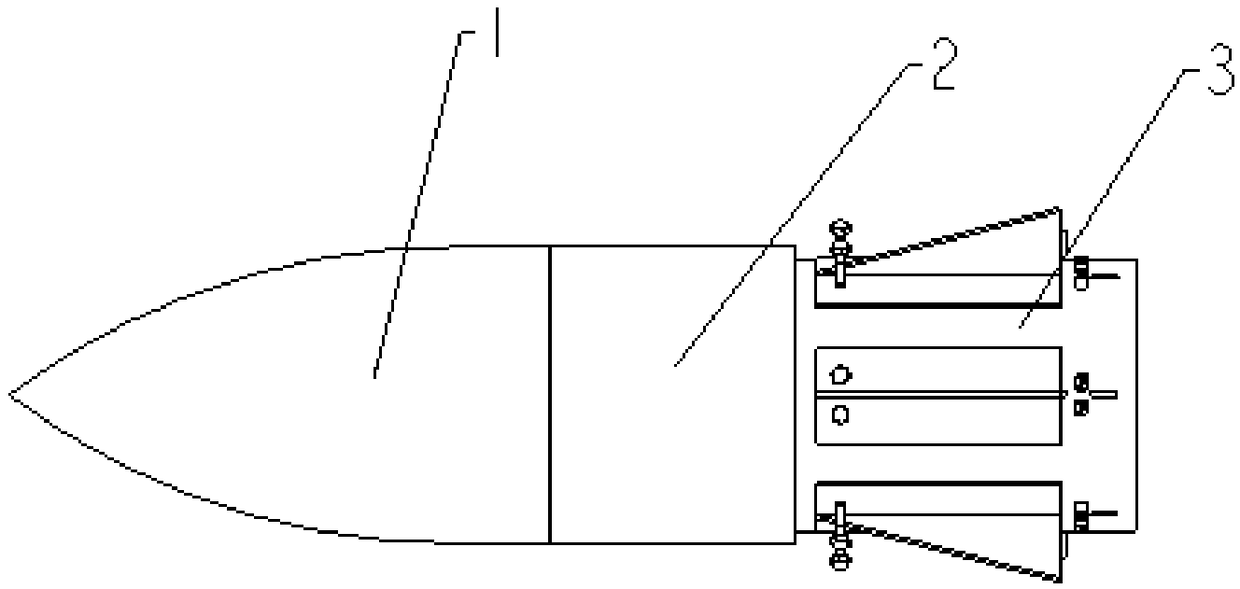

Pre-splitting warhead

InactiveCN103292638APrecision strikeCompact structureAmmunition projectilesProjectilesEngineeringPyrotechnic fastener

The invention relates to a pre-splitting warhead comprising a plurality of reduced projectile body sections, wherein each projectile body section is formed by a plurality of shells in an enclosing way; a delay fuse is arranged in a projectile body; the projectile body sections are connected through connectors; a hoop is arranged at the periphery of each projectile body section; the hoops tightly hoop the projectile body; and explosive bolts are mounted on the hoops. Before the warhead gets close to a target, the warhead is detonated through the explosive bolts and the delay fuse, the projectile body is decomposed into a plurality of shells or special-shape projectiles and the target can be attacked on a large scale; and since the quantity of the shells is large, a defense system cannot resist the attack and precise attacks to large warships, airplanes or guided missiles can be realized.

Owner:仇寿平

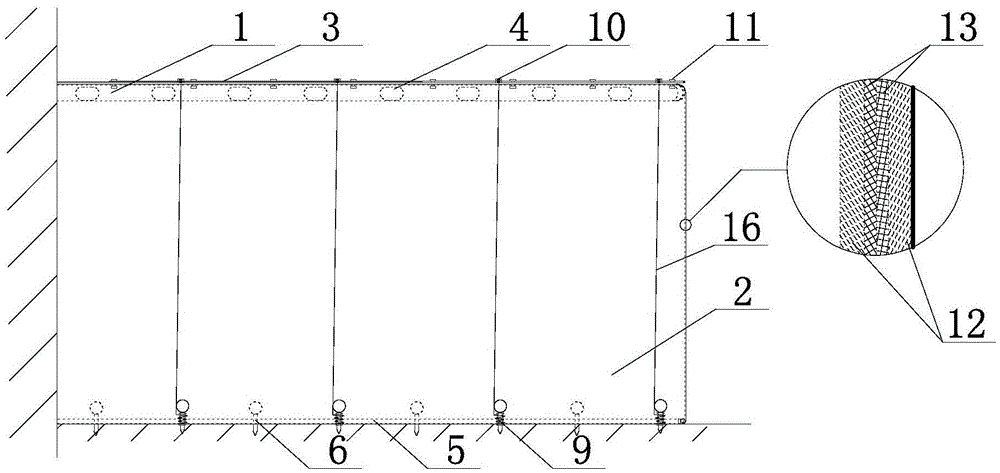

Detonated floating type fence for blocking soluble hazardous chemical leakage of medium- and small-scale docks

InactiveCN105603951AEasy to useWill not expand the scope of pollutionWater cleaningEngineeringPyrotechnic fastener

The invention discloses a detonated floating type fence for blocking soluble hazardous chemical leakage of medium- and small-scale docks. The detonated floating type fence comprises a U-shaped top fixing device, floating bodies, an apron body, a bottom binding device and a bottom fixing device, wherein the U-shaped top fixing device is arranged at the upper parts of the floating bodies, the upside of the apron body is connected with the top fixing device, the downside of the apron body is wrapped with the bottom fixing device, the floating bodies are a plurality of floating pads which are uniformly spaced, the bottom binding device comprises explosive bolts and two steel wire ropes, and the two steel wire ropes tied onto the explosive bolts are separately connected with the top fixing device and the bottom fixing device. According to the detonated floating type fence for blocking the soluble hazardous chemical leakage of the medium- and small-scale docks, when not in use, the detonated floating type fence sinks to the bottom of a river due to the binding action of the explosive bolts and the steel wire ropes, so that the normal use of a river way, and the navigation and loading and unloading of ships are not affected; when a leakage accident occurs, the explosive bolts explode, the steel wire ropes are loosened, and the apron body rapidly floats under the action of the floating bodies, so that a fully-closed space is formed, polluted water is fully isolated in the closed space, and a water pollution range cannot be enlarged.

Owner:HOHAI UNIV

Combined separation parachute opening mechanism

InactiveCN108151592AGuaranteed connection strengthReduce shock overloadAmmunition projectilesProjectilesDetonationRocket

The invention relates to a combined separation parachute opening mechanism, and belongs to the field of civil rocket dispenser bombs. In the separation parachute opening mechanism, the inner wall of an annular connecting table at the middle part of an inner cavity of a separation cylinder is in threaded connection with a stop ring; a separation push plate and a separation bullet are charged on thefront side, where the stop ring is fixed, of the separation cylinder; a stable parachute at the back end of the separation bullet is fixed with a front side plate surface of the separation push platethrough a shearing rope; the separation push plate and the stop ring are synchronously fixed through an explosion bolt and a rupture bolt; the front end of a limiting bolt penetrates through a limiting bolt passing hole in a ring surface of the stop ring, and is in threaded fixation with the separation push plate; the limiting bolt is positioned on the back side of the plate surface of the separation push plate with a mobile margin; a separation explosive box is fixed on the back side plate surface of the separation push plate; the back end of the separation cylinder is in threaded butt jointwith a back end projectile body; and the explosion bolt and a detonation circuit of the separation explosive box are connected with a delay fuse mounted on the back end projectile body through leads.The separation mechanism effectively guarantees the connecting strength in the rocket projectile flight process, and is high in separation reliability and controllable in parachute opening time.

Owner:JINXI IND GRP

A Strongly Sealed Explosive Bolt Device

ActiveCN107191459BEnhanced anti-explosion sealing abilityAvoid failureScrewsSelf-propelled projectilesRubber ringEngineering

Owner:BEIJING INST OF SPACECRAFT SYST ENG

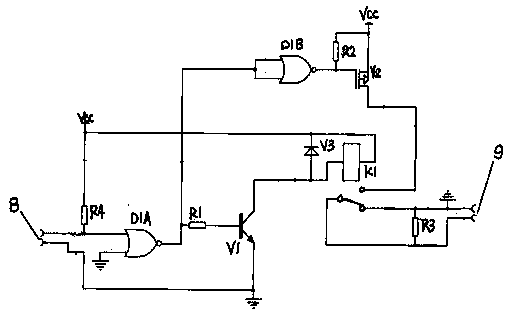

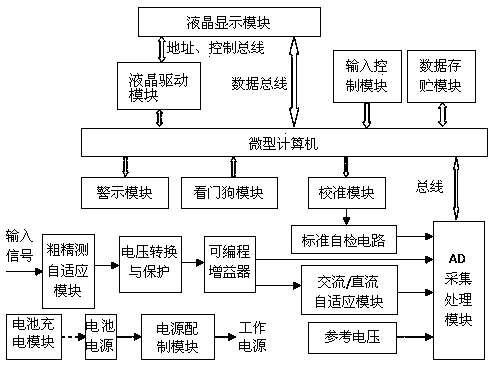

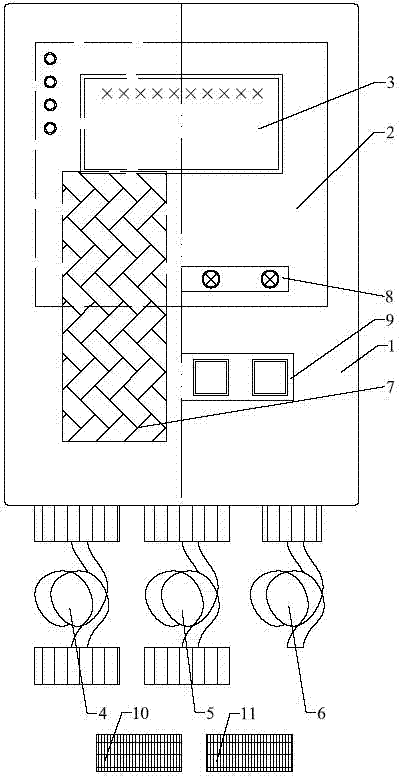

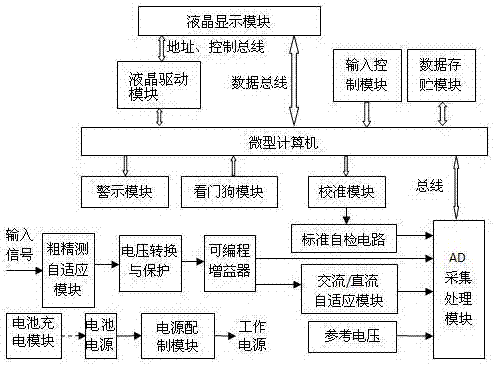

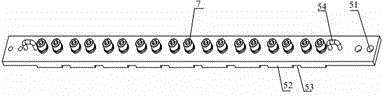

Explosive bolt and booster dynamic or static voltage tester for missile ship surface equipment

ActiveCN107449960BEasy to useAdapt to use requirementsElectrical testingMeasurement using digital techniquesLiquid-crystal displayComputer module

The invention provides a missile ship surface equipment explosive bolt and booster dynamic / static voltage tester, which comprises a reinforced case, a measurement and control main board, a liquid crystal display screen, an explosive bolt signal measuring cable, a booster signal measuring cable, a lithium battery power supply and a charging module. Through automatic judgment and detection technology of AC and DC strong / weak voltage signals of leakage, induction and working voltage of explosive bolts and boosters of different XX series models of missile ship surface equipment, the difficulty of online real-time automatic detection of complex voltage signals of the explosive bolts and boosters of the XX series missile ship surface equipment is solved, and the problem of refined automatic quantitative processing of different types of signals is processed.

Owner:PLA DALIAN NAVAL ACADEMY

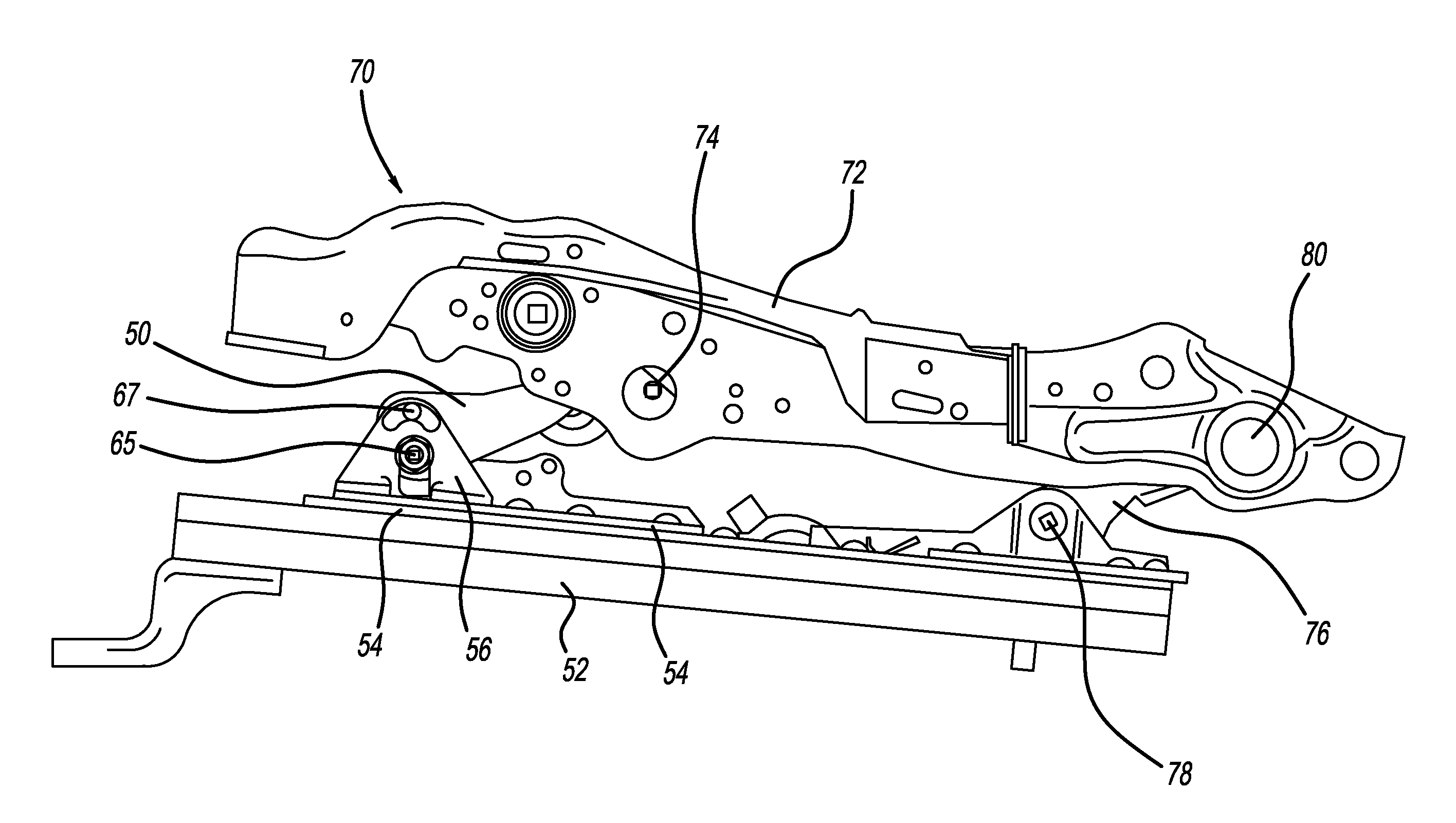

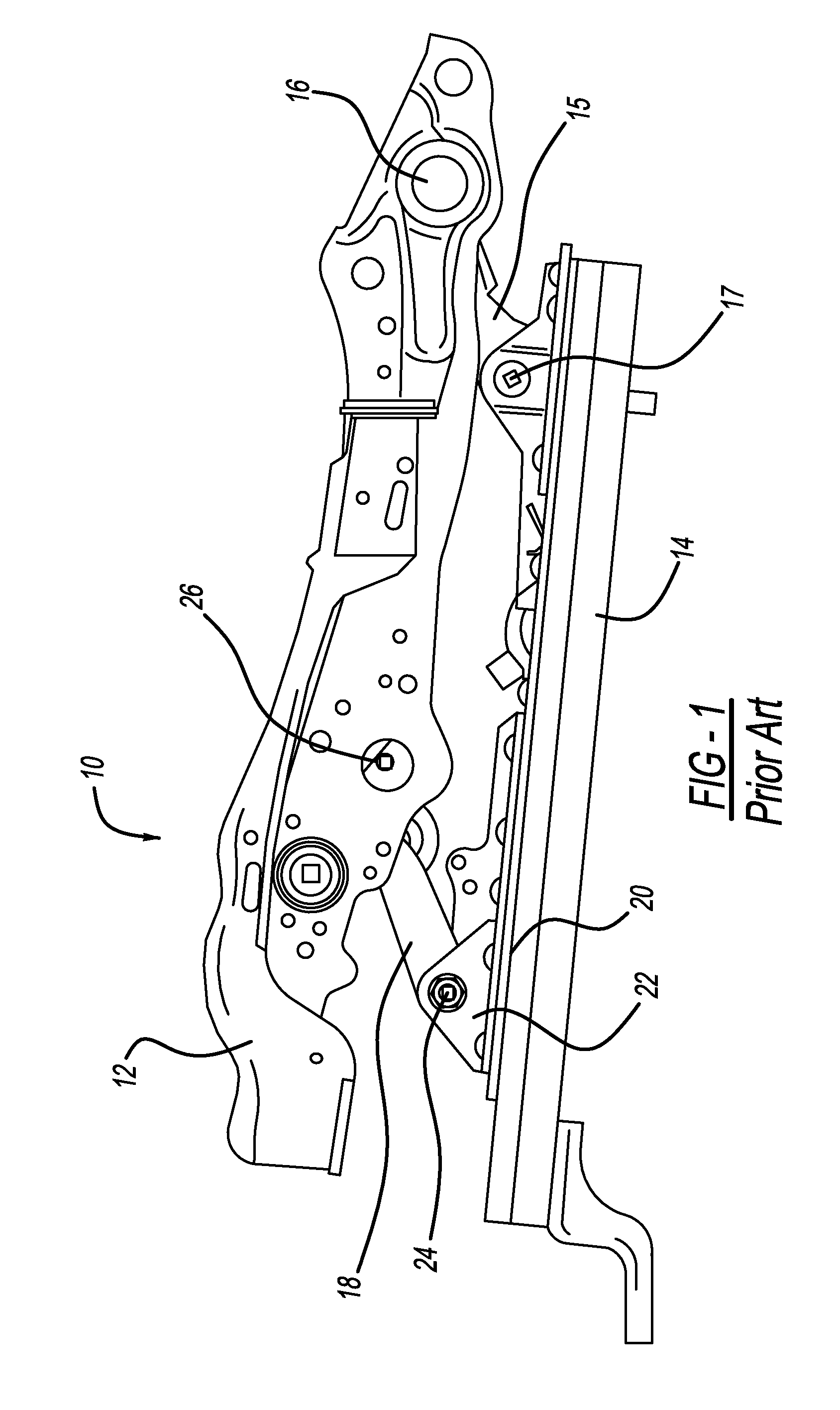

Pyrotechnic fastener seat arrangement for unbelted occupant protection

ActiveUS9308842B2Improve protectionVehicle seatsPedestrian/occupant safety arrangementPyrotechnic fastenerFastener

A seat assembly including a seat pan that drops vertically in the event of a frontal impact event to help safeguard against the head of an unbelted seat occupant striking the headliner, windshield or other components of the vehicle. The seat assembly includes a seat pan attached to a seat track. The seat track further includes an attachment bracket. A swing linkage movably connects the seat pan with the seat track by a movable fastener. A slot is formed in the bracket through which at least a part of the movable fastener passes. A pyrotechnic fastener also attaches the swing linkage to the bracket. In a frontal impact event, the pyrotechnic fastener is caused to explode thus separating the pyrotechnic fastener into two parts and allowing the swing linkage and its attached seat pan to drop vertically relative to the seat track and lowering the unbelted occupant.

Owner:FORD GLOBAL TECH LLC

Missile ship surface equipment explosive bolt and booster dynamic/static voltage tester

ActiveCN107449960AEasy to useAdapt to use requirementsElectrical testingMeasurement using digital techniquesLiquid-crystal displayMarine engineering

The invention provides a missile ship surface equipment explosive bolt and booster dynamic / static voltage tester, which comprises a reinforced case, a measurement and control main board, a liquid crystal display screen, an explosive bolt signal measuring cable, a booster signal measuring cable, a lithium battery power supply and a charging module. Through automatic judgment and detection technology of AC and DC strong / weak voltage signals of leakage, induction and working voltage of explosive bolts and boosters of different XX series models of missile ship surface equipment, the difficulty of online real-time automatic detection of complex voltage signals of the explosive bolts and boosters of the XX series missile ship surface equipment is solved, and the problem of refined automatic quantitative processing of different types of signals is processed.

Owner:PLA DALIAN NAVAL ACADEMY

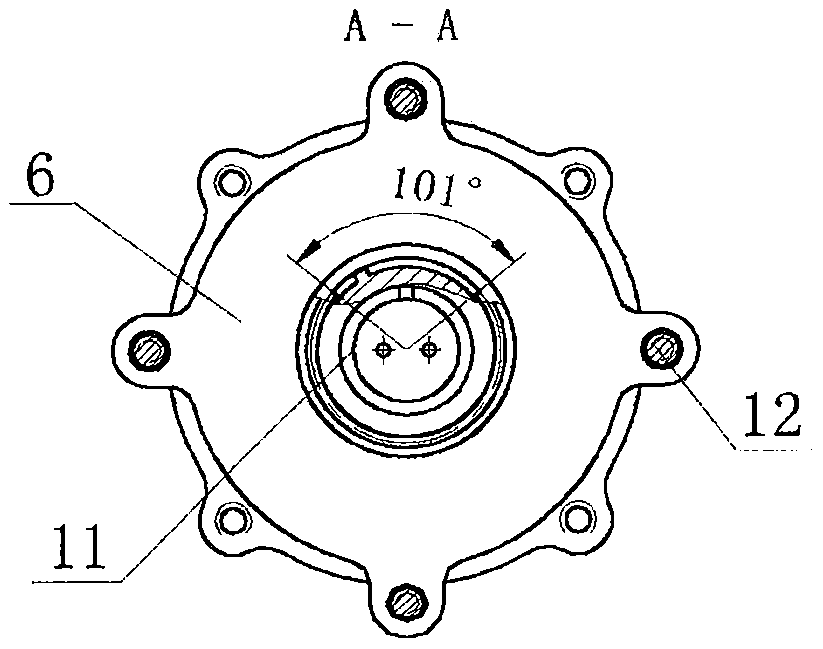

A Limit Compensation Mechanism of Explosive Bolt Separation Device

ActiveCN105490087BSolve installation and replacementHigh replaceabilityVehicle connectorsCoupling device detailsElectrical connectionPower filter

The invention provides a limit compensation mechanism of an explosive bolt separation device, the mechanical structure of which includes fastening a support base (4) on a separation fixing base (3) with screws (13), and securing a socket box with screws (12). (6) Fastened on the support seat (4); its electrical structure includes an external plug seat (9) and a two-core plug (11), wherein the external plug seat (9) is connected to the two-core plug through a power filter (10) On the plug (11), the two-core plug (11) is connected to the socket end of the explosion bolt (5) by direct insertion to complete electrical connection; between the two-core plug (11) and the socket box (6), a certain The floating limit structure of the gap (h). The invention solves the problem that the explosive bolt has a simple structure and sufficient mechanical strength, and also ensures very reliable explosive separation. It is very convenient to install and replace in the outfield and infield, reliable in work and good in disassembly and replacement.

Owner:SHAANXI FENGHUO ELECTRONICS

An aerospace stand-alone locking and releasing mechanism

An astronavigation stand-alone locking and releasing mechanism comprises a mounting frame and a plurality of compression bars. The mounting frame is arranged at the bottom in a spacecraft cabin. An astronavigation stand-alone is disposed in the mounting frame. Two ends of each compression bar are connected with the mounting frame through explosive bolts respectively. The astronavigation stand-alone is locked in the mounting frame. The astronavigation stand-alone locking and releasing mechanism can tightly lock the astronavigation stand-alone when the spacecraft is launched, and easily unlock the astronavigation stand-alone during in-orbit maintenance of the astronavigation stand-alone.

Owner:上海航天技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com