Sensor and explosive bolt on pressure vessel gate

A technology of pressure sensor and pressure vessel, applied in pressure vessel, vessel discharge method, vessel filling method, etc., can solve the hazard of combustible medium combustion and secondary space explosion, a large amount of sediment or powdery adherent, obstructing safety valve Operation and other issues to ensure safety, ease of use, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

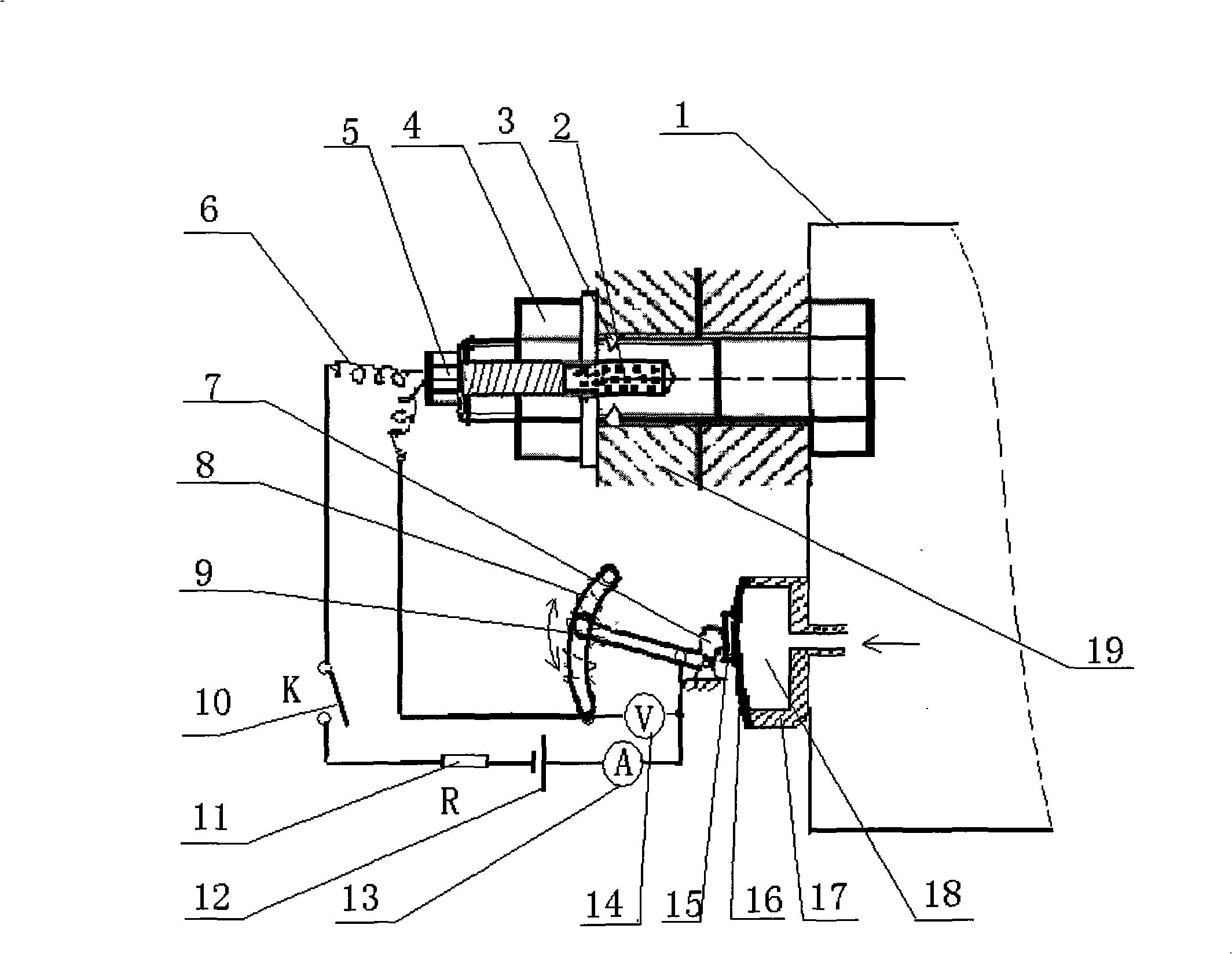

[0016] Such as figure 1 As shown, the main components of the present invention are arranged on the pressure vessel door panel 19, that is, the bolt on the hinge of the pressure vessel door is changed into an explosion bolt, and when the explosion bolt explodes, the pressure vessel door opens automatically to relieve pressure. The pressure vessel will not explode, which plays a role in protecting the pressure vessel. The present invention mainly consists of a pressure sensor and an explosion bolt, wherein the explosion bolt is composed of an explosive 2, a reserved groove 3, a pressure vessel hinge outer nut 4, an explosive replacement screw 5 and an electrified wire 6, wherein the explosion bolt on the outer side of the pressure vessel A ring-shaped reserved groove 3 is set to cause stress concentration, so that when the explosion is broken along the ring-shaped reserved groove 3, the reserved groove is arranged on the outside of the pressure vessel, so that when the explosion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com