Non-pyrotechnic separation device based on explosive bolt

A technology of explosive bolts and separation devices, which is applied in the direction of projectiles, self-propelled bombs, offensive equipment, etc., can solve the problems of polluting the environment, generating harmful gases, and pyrotechnic separation and unlocking devices can only be used once, so as to reduce costs, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

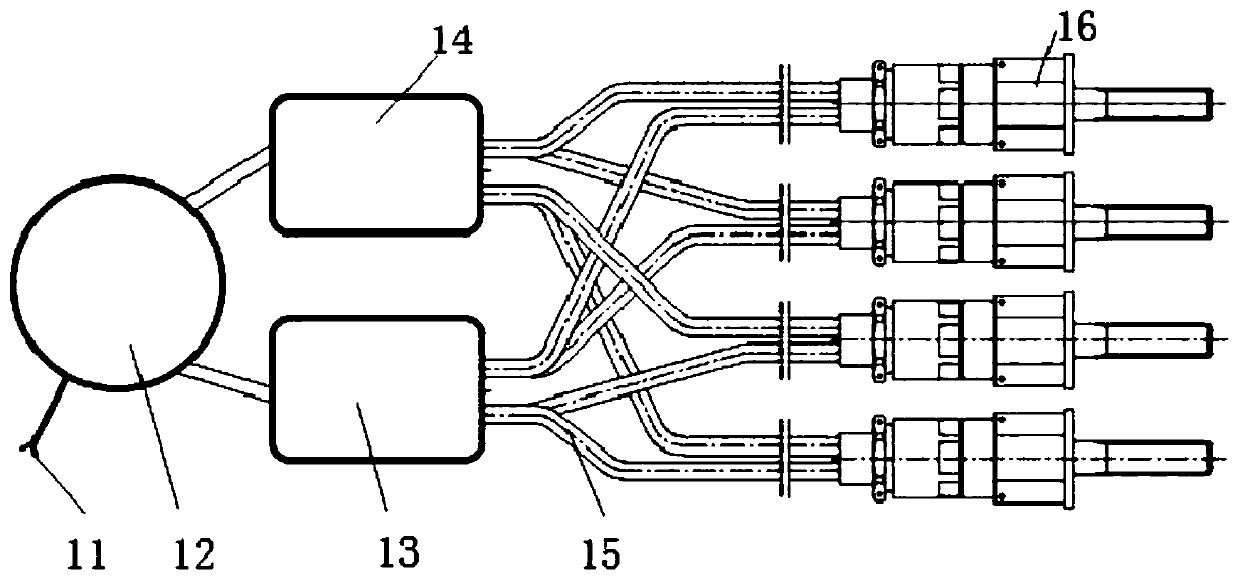

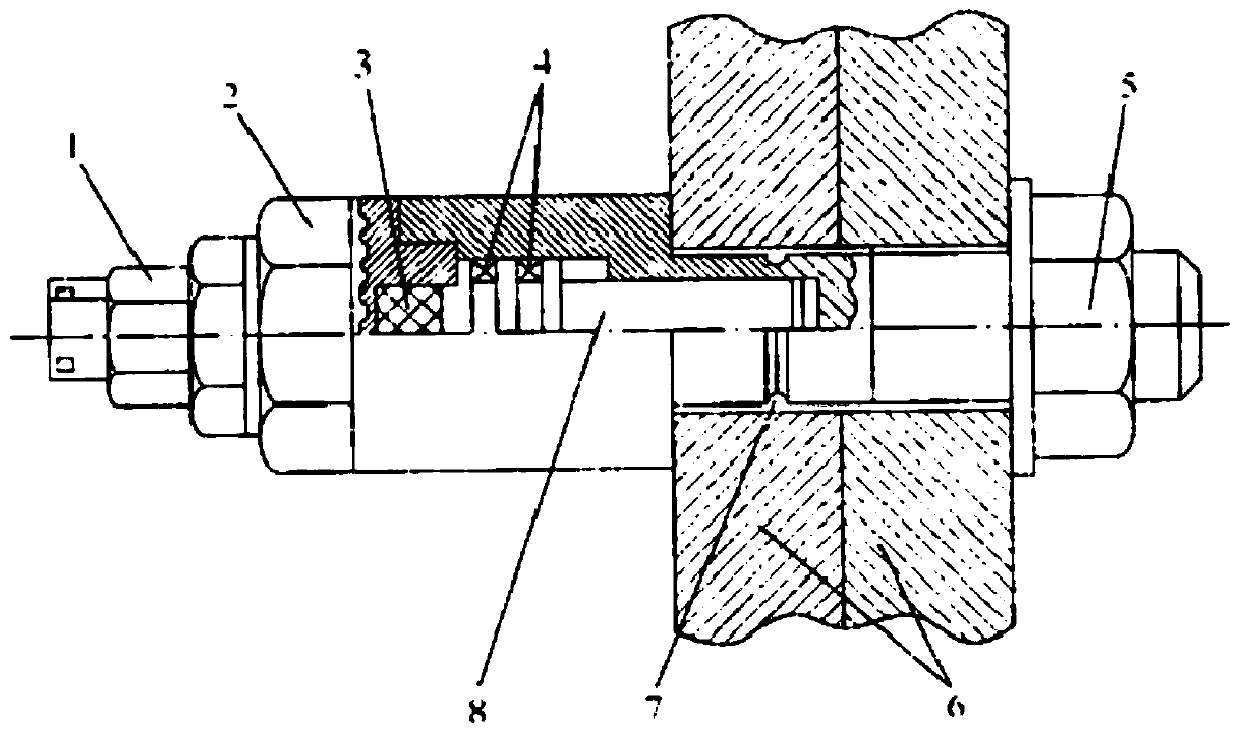

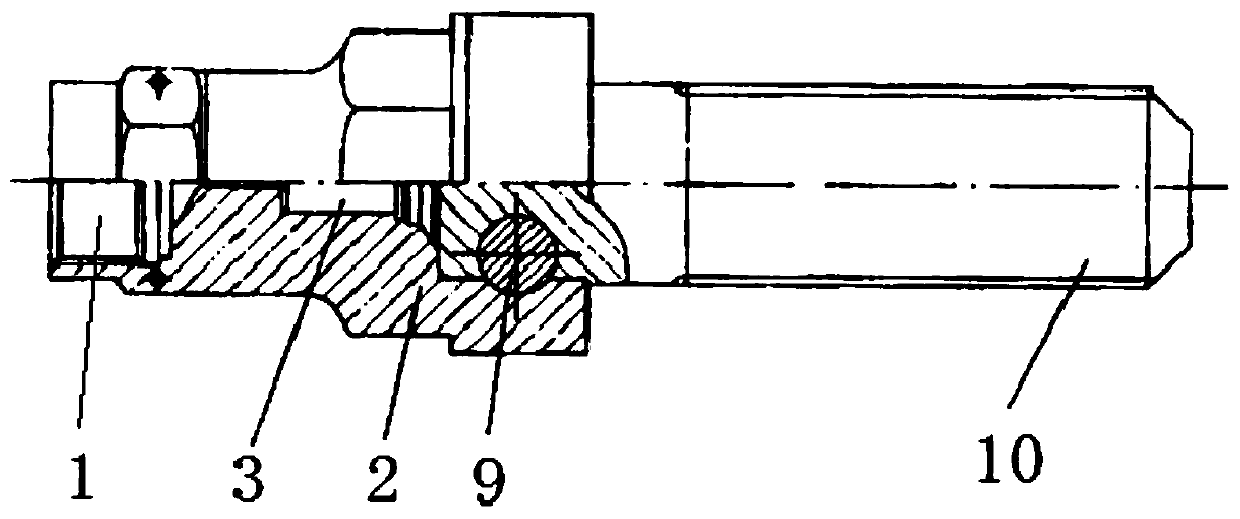

[0031] Such as Figure 1-3 A specific implementation of the shown non-pyrotechnic separation device based on explosive bolts includes:

[0032] At least one explosive bolt 16 is provided with an air cavity 3 for containing high-pressure gas inside;

[0033] At least one high-pressure gas cylinder 12 communicates with the air cavity 3 of the explosive bolt 16 through at least one pipeline 15, and is used to transport the high-pressure gas stored inside to the air cavity 3 of the explosive bolt 16 through the pipeline 15 and apply force to the explosive bolt 16 to separate it.

[0034] The front end of the high-pressure gas cylinder 12 is also provided with an inflation valve 11. Before the launch of the carrier rocket, the high-pressure gas cylinder 12 is charged with high-pressure gas (the high-pressure gas is about 30-90Mpa) through the inflation valve 11 in advance, thereby storing the high-pressure gas at a high pressure. In the gas cylinder 12, at least one high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com