Large scale solid engine drop test release device

A technology of solid motor and drop test, applied in the field of release device and drop test release device, can solve the problems of large volume and mass of large solid motor, high requirements for release consistency and stability, and inability of release device to meet the requirements, and achieves a high level of improvement. Test precision control, good action synchronization, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

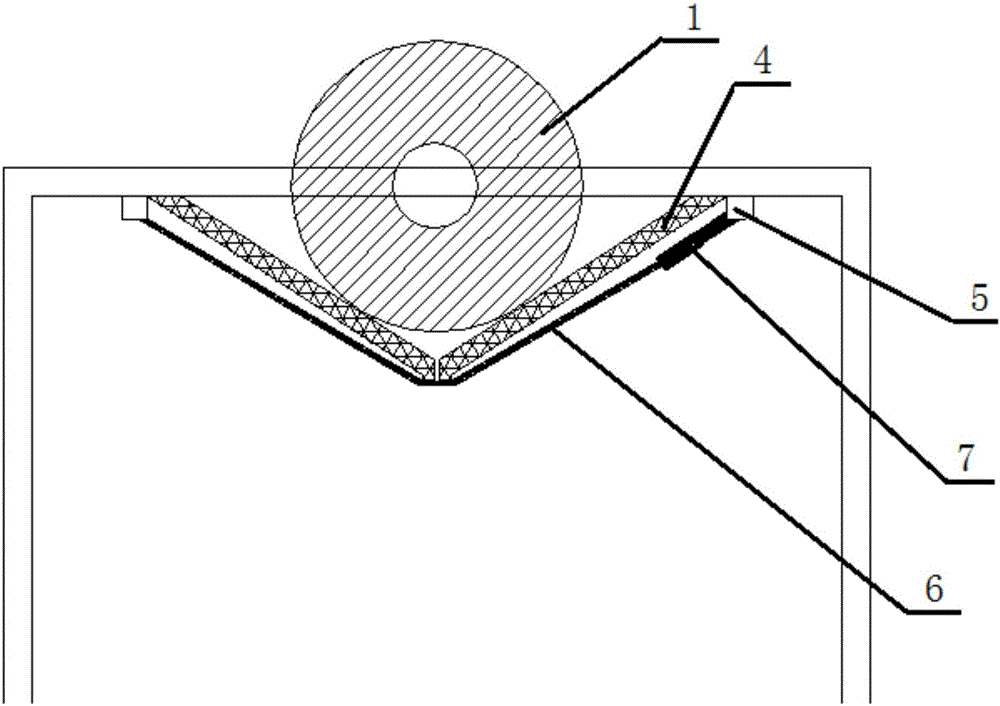

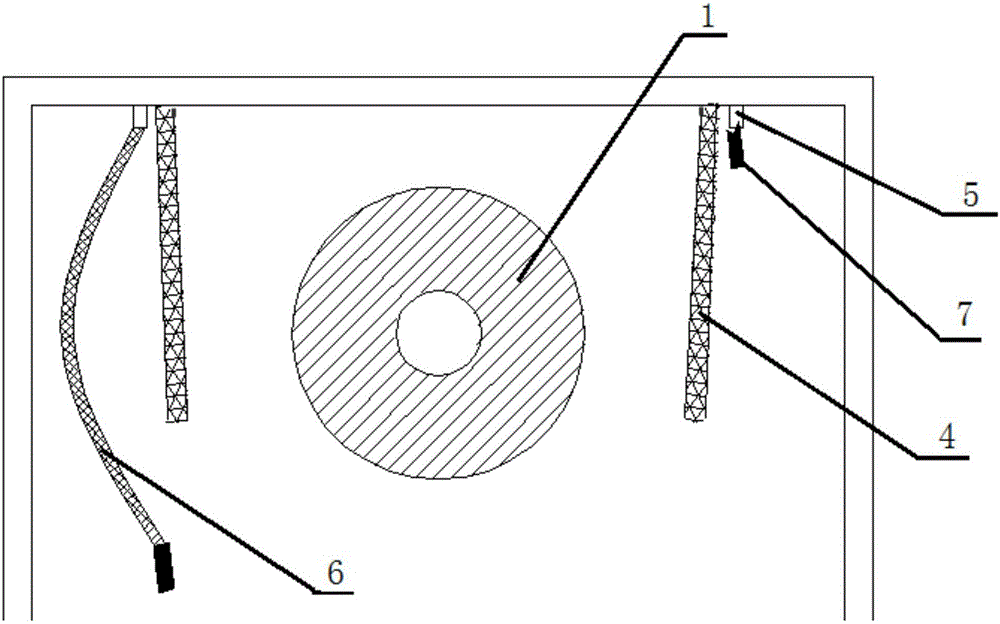

[0019] This embodiment provides a new opening release device for the drop test of a large engine (2m in diameter, about 3m in length, and 12t in weight). The method, combined with the opening and release of the explosive bolt, not only solves the clamping problem, but also improves the control accuracy of the test.

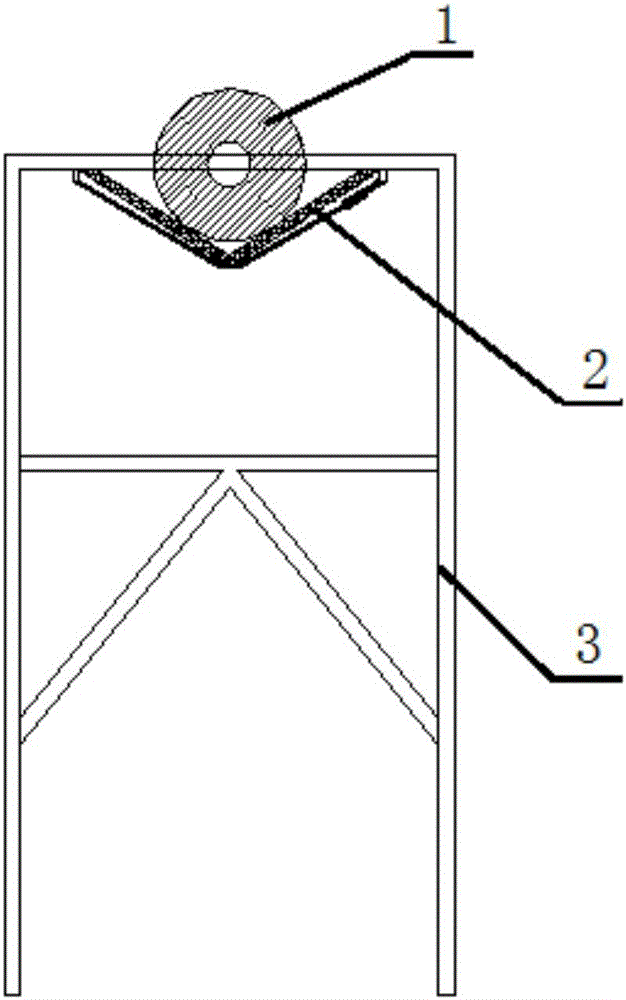

[0020] The release device needs to be placed on the drop tower 3, the design load of the drop tower 3 is 25t, it is a steel structure, and the material is Q235B. Such as figure 1 As shown, the release structure 2 is installed on the two beams in the middle of the drop tower 3. Before the drop test, the tested engine 1 is placed on the release mechanism 2 according to the specified height. During the test, the release mechanism 2 works, and the tested engine 1 is quickly released. , falling freely to the ground while maintaining the specified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com