Detonated floating type fence for blocking soluble hazardous chemical leakage of medium- and small-scale docks

A technology for soluble and hazardous chemicals, which is applied in the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of leakage of hazardous chemicals, lack of complete isolation of water bodies polluted by soluble hazardous chemicals, and achieve the effect of expanding the scope of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

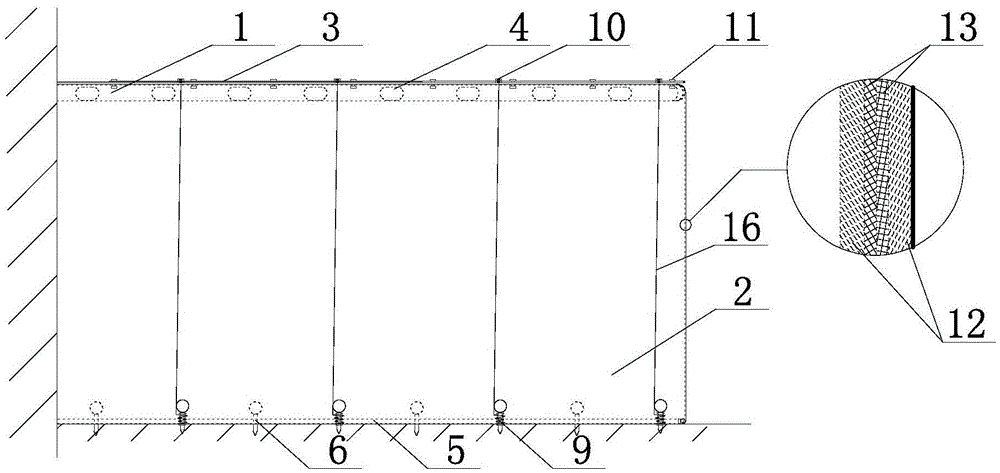

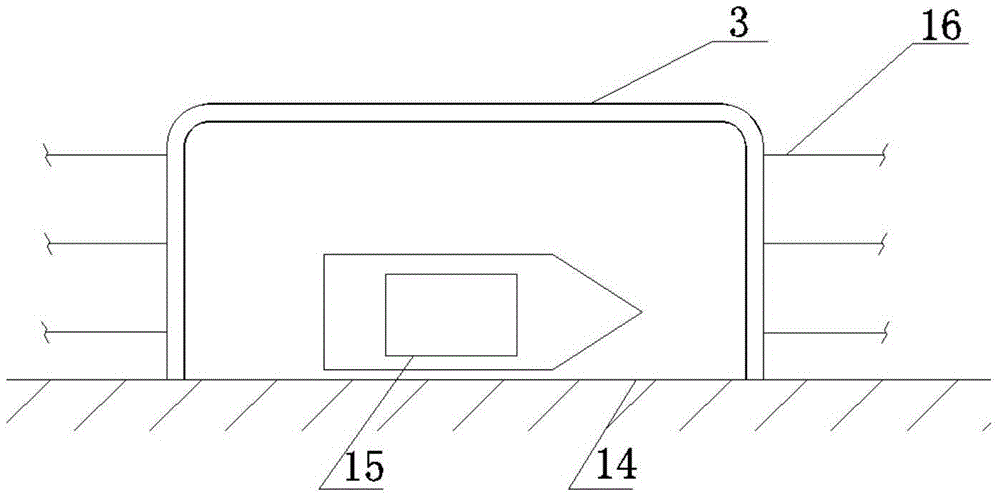

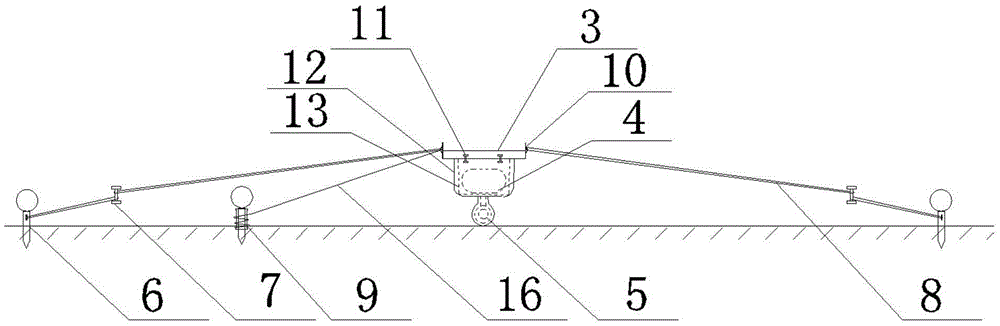

[0016] like Figure 1 to Figure 3 As shown, a detonating floating fence for blocking the leakage of soluble hazardous chemicals in small and medium-sized wharves of the present invention includes a U-shaped top fixing device, a floating body 1, a skirt body 2, a bottom restraining device and a bottom fixing device. The floating body 1 is a plurality of evenly spaced floating pads 4, which are sealed and wrapped by the skirt body 2; the U-shaped top fixing device is preferably an integrated aluminum alloy plate 3, placed on the upper part of the skirt body 2 wrapping the floating pads 4, And fix the aluminum alloy plate 3 and the skirt body 2 with bolts 11 at the interval of the floating pad 4; wrap the stainless steel pipe 5 under the skirt body 2, and fix it on the hard layer at the bottom of the water with a stainless steel brazing 6 to form a fully enclosed enclosur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com