Method and device for forecasting and pre-warning downhole abnormal working conditions in real time in shale gas fracturing processes

A technology for abnormal working conditions and real-time prediction, applied in prediction, earthwork drilling, wellbore/well components, etc., it can solve problems such as failure of real-time monitoring to be solved, and achieve the effect of improving prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

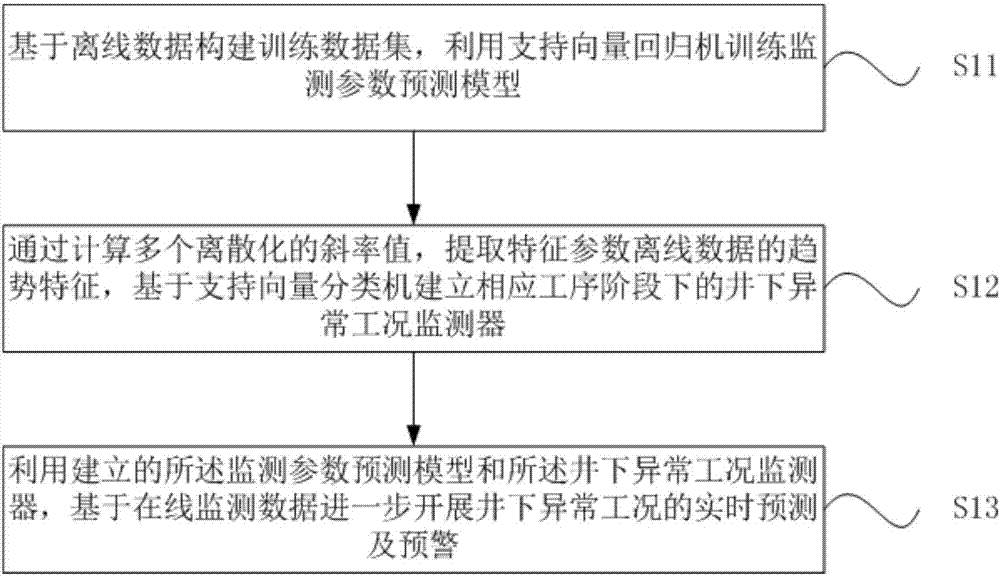

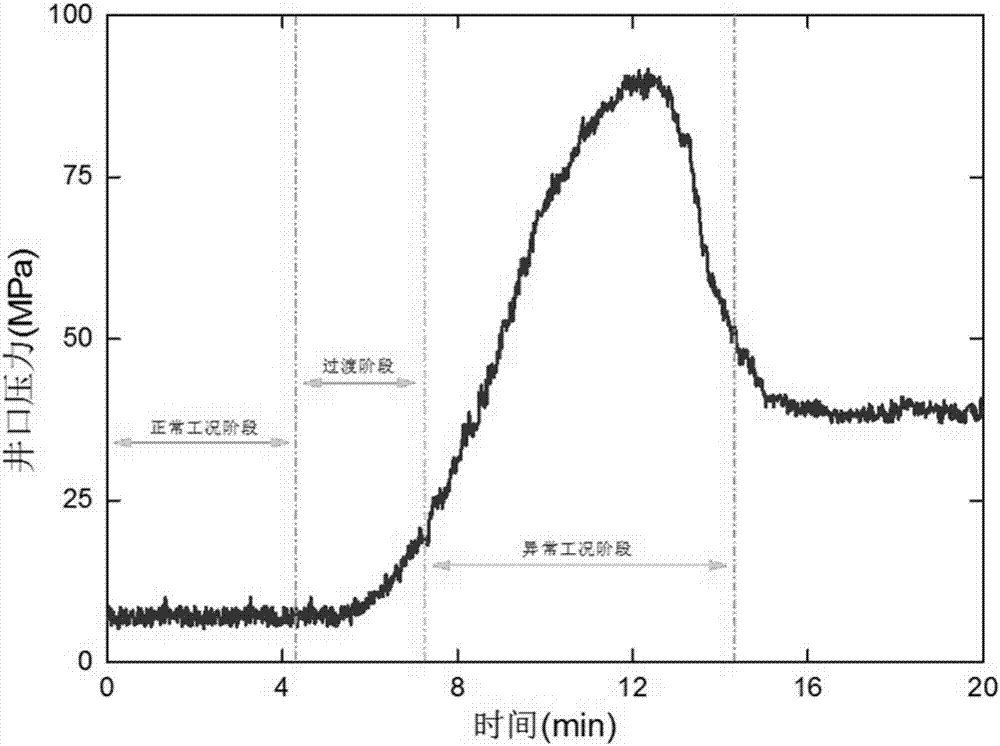

[0080] In this embodiment, the downhole operating conditions at the "pumping prefluid" stage during the fracturing process of the "Jiaoye Plate" shale gas well are used as the case object to verify the accuracy and applicability of the present invention. Wellhead pressure and displacement are characteristic parameters of abnormal working conditions during the "pump injection of prefluid" stage. Therefore, it is necessary to establish a prediction model for wellhead pressure and displacement. Next, take the wellhead pressure prediction model as an example to show the modeling steps.

[0081] 1. Establish a prediction model for monitoring parameters

[0082] 1.1) Build a training data set

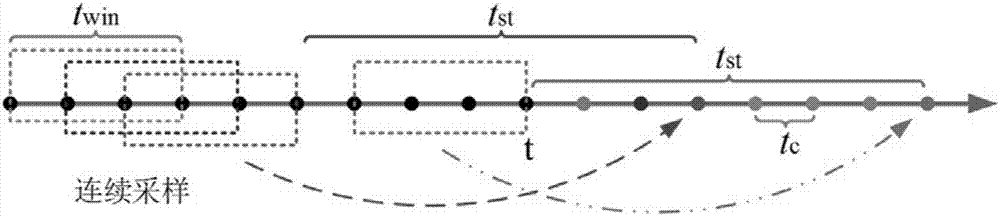

[0083] Set the time window width t win =1min, prediction step length t st =1min, sampling period of wellhead pressure t c =2s, therefore, according to formula (1), the total number of time series data in each time window V=30.

[0084] Select H=10 sets of wellhead pressure time series data, respec...

no. 2 example

[0111] This embodiment provides a technical solution for a real-time prediction and early warning device for abnormal downhole working conditions during shale gas fracturing. In this technical solution, the device for real-time prediction and early warning of abnormal downhole operating conditions during shale gas fracturing includes: a model building module 91, a model training module 92, and an early warning module 93.

[0112] The model building module 91 is used to build a training data set based on offline data, and use a support vector regression machine to train a monitoring parameter prediction model.

[0113] The model training module 92 is used for extracting trend characteristics of offline data of characteristic parameters by calculating a plurality of discretized slope values, and establishing a downhole abnormal working condition monitor in the corresponding process stage based on the support vector classifier.

[0114] The early warning module 93 is configured to use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com