Vehicle Pneumatic Tires

A technology for pneumatic tires and vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., can solve problems such as improving drainage capacity, unfavorable braking performance, and unfavorable effects of circumferential rib stability, achieving good The effect of braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

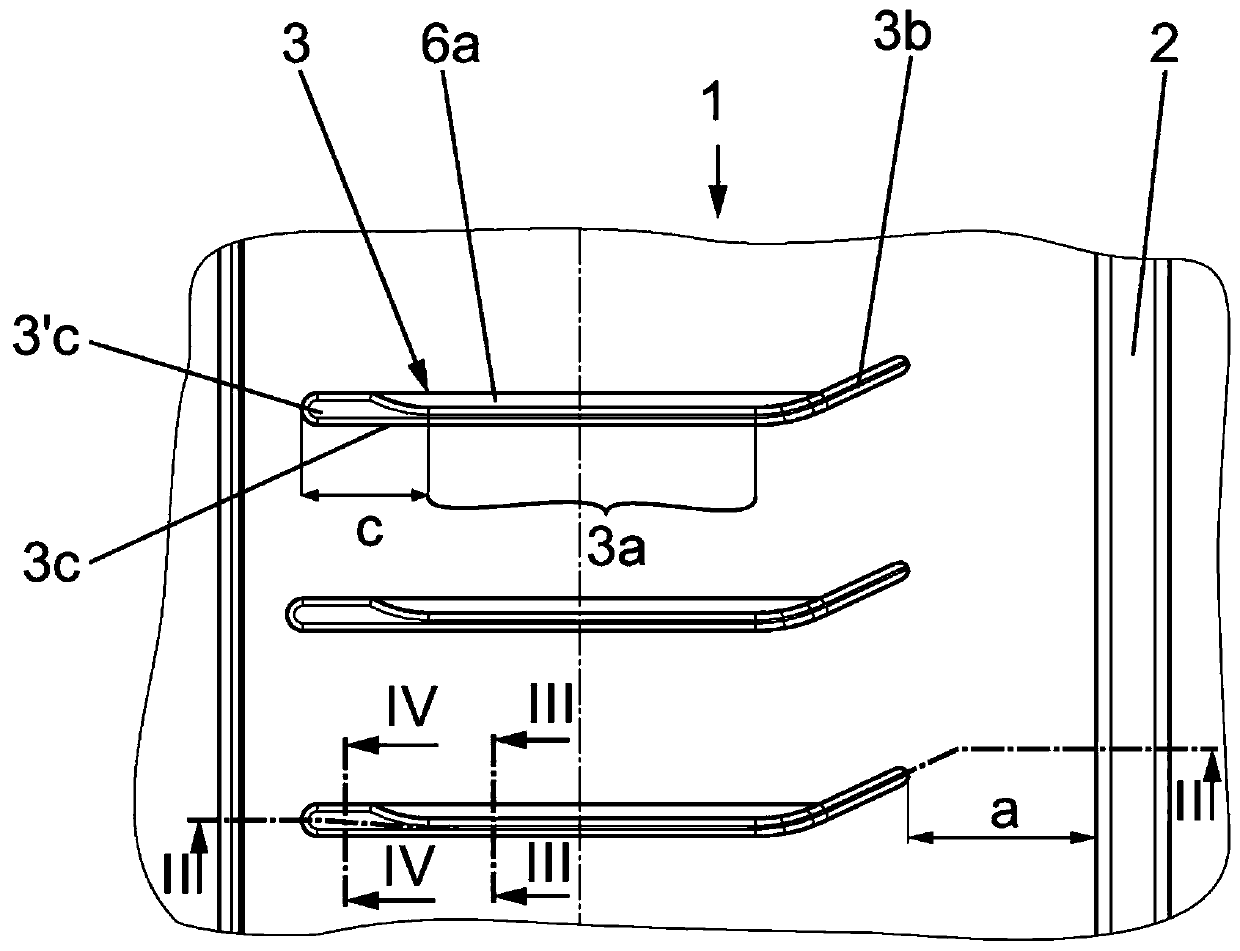

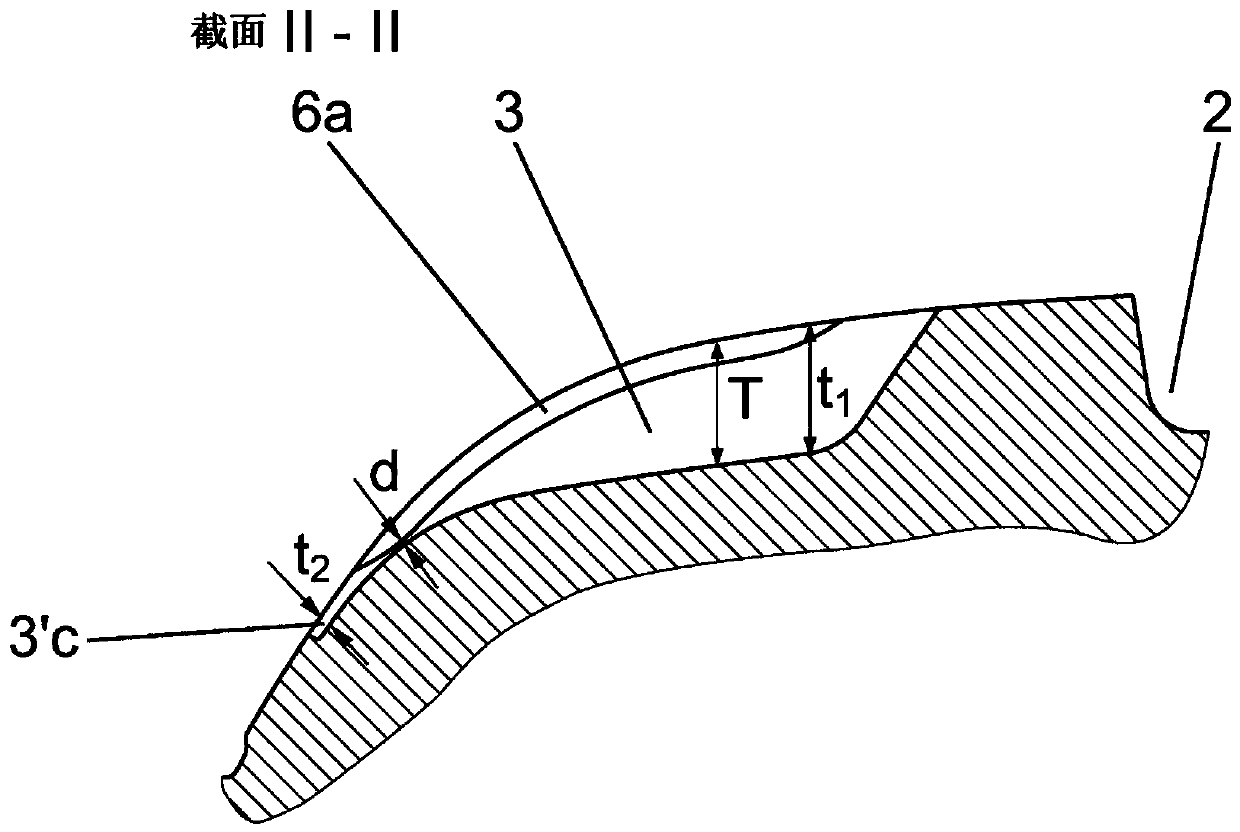

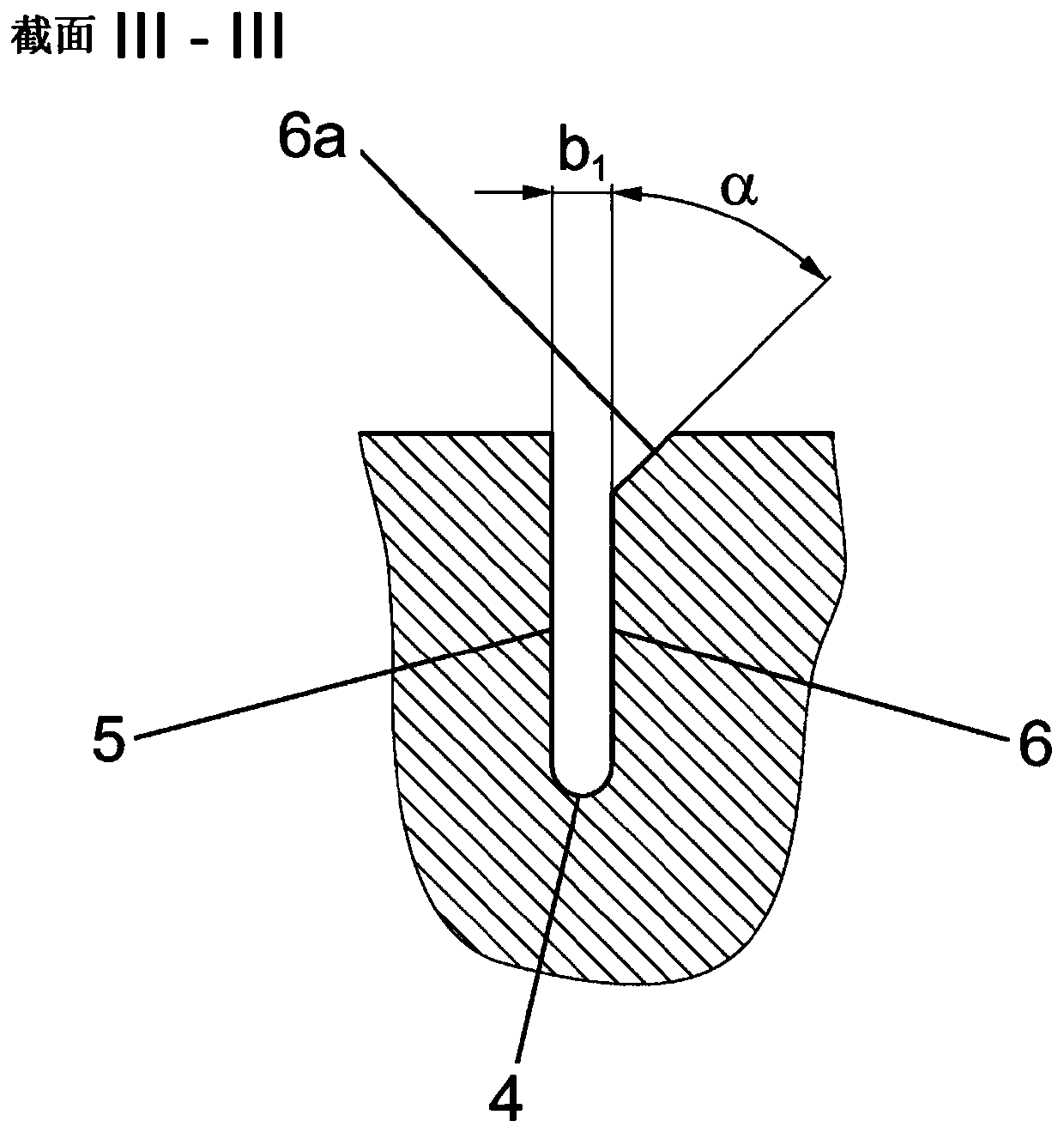

[0017] figure 1 A section of the circumference of a structural rib 1 running at the shoulders of a pneumatic vehicle tire tread in radial structure for passenger cars, vans and the like is shown. The ribs 1 are separated by circumferential grooves 2 surrounding in the circumferential direction from the tread elements adjoining the middle of the tread, such as rows of blocks or other ribs surrounding in the circumferential direction. The block-like structure of the rib 1 is produced by the transverse grooves 3 running in the rib 1 and formed in the form of cutouts. exist figure 1 In the embodiment shown in , the transverse grooves 3 run almost precisely in the transverse direction of the tread linearly or substantially linearly with a relatively small mutual distance of 10 mm to 17 mm, wherein the transverse grooves 3 can also run relatively An acute angle of up to 30° runs in the precise transverse direction of the tread. The transverse groove 3 is composed of a central gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com