Method and device for coating a metal strip with a coating material which is at first still liquid

A technology of coating materials and metal strips, which is applied in the direction of metal material coating process, coating, hot dip plating process, etc., to achieve the effect of simplifying execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention is described in detail below in the form of an example with reference to the mentioned figures. In all figures, the same technical elements are marked with the same reference numerals.

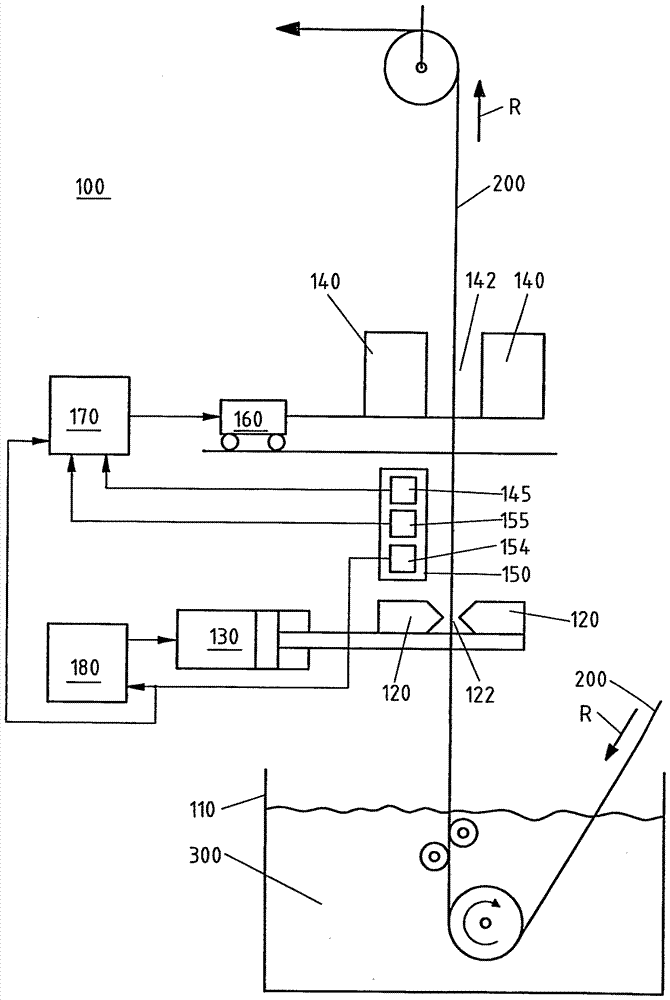

[0021] figure 1 A device 100 according to the invention is shown for coating a metal strip 200 with a liquid coating material 300 , eg zinc. For this purpose, the initially still uncoated metal strip 200 is guided in the transport direction R into a paint container 110 which is filled with a liquid coating material. Inside the paint container 110, the metal strip 200 is deflected by means of deflection rollers so that it leaves the paint container upwards. After passing through the paint container, the still liquid coating material adheres to the metal strip 200 .

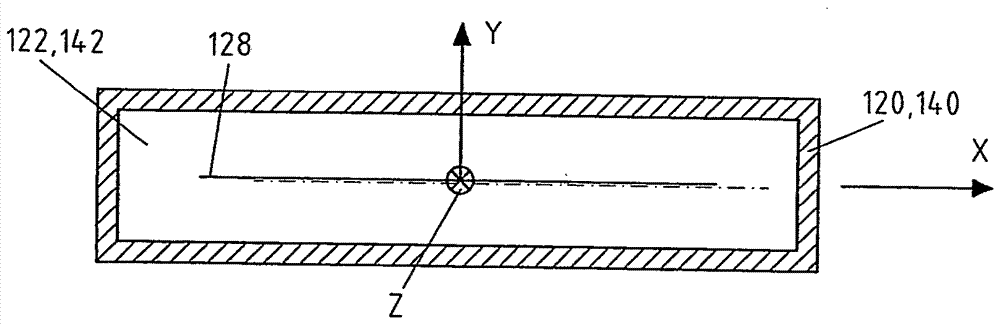

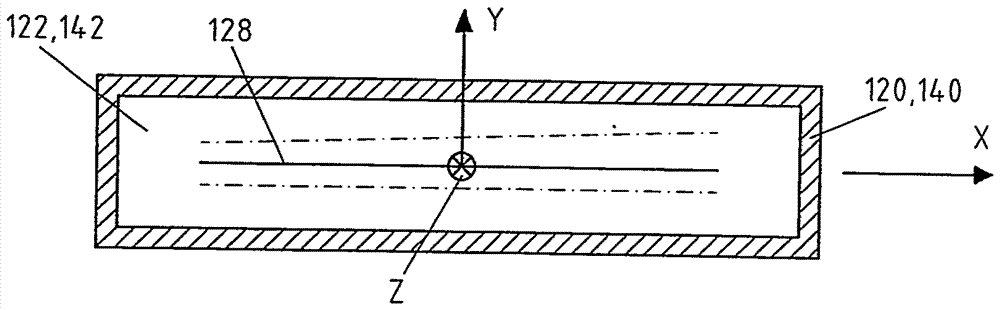

[0022] Arranged above the paint container 110 is a purging device 120 which opens a slit 122 through which a metal strip 200 is guided. Excess coating material is blown off the surface of the metal strip 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com