Multi-purpose and multifunctional gluing device

A gluing device and multi-functional technology, which can be applied to devices and coatings that apply liquid to the surface, can solve problems such as the decline in gluing quality and the residual glue of the nozzle, and achieve a convenient use, novel structure, and suitable for popularization and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

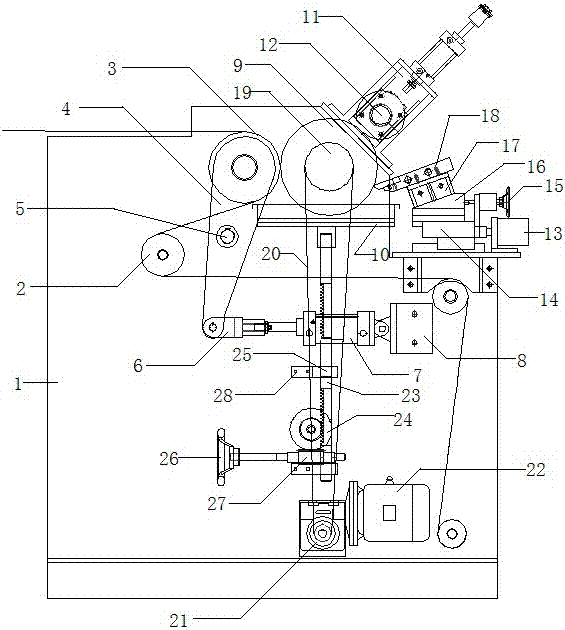

[0015] Such as figure 1 Shown is a schematic structural view of the present invention, the present invention is a multi-purpose multifunctional gluing device, including a frame 1, a feed roller 2, a pressure roller 3 and a gluing mechanism.

[0016] Leading rollers 2 are arranged in a staggered manner from bottom to top, and are rotatably connected with frame 1 .

[0017] The pressure roller 3 is mounted on the top of the connecting rod 4, and is located on the frame 1 near the gluing mechanism; the middle part of the connecting rod 4 is rotationally connected with the frame 1 through the connecting rod support pin 5, and the bottom of the connecting rod 4 is rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com