Grinding assembly line for strip-shaped stones

An assembly line and stone technology, which is applied in the direction of grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of easily damaged stone, uneven thickness, and troublesome handling, so as to save handling links and reduce grinding time, to solve the effect of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

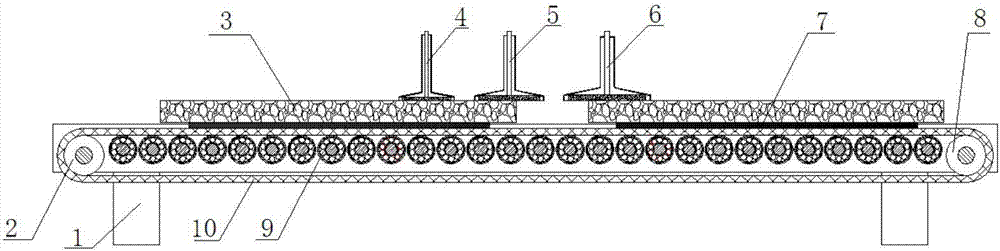

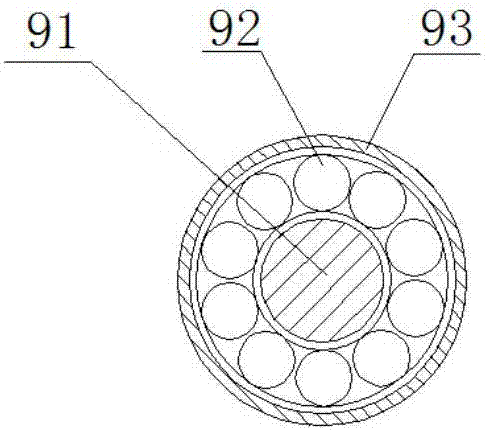

[0016] Such as figure 1 and figure 2 A strip stone grinding assembly line shown includes a mounting frame 1, a transmission wheel A2, a polishing grinding head assembly 4, a fine grinding grinding head assembly 5, a rough grinding grinding head assembly 6, a driving wheel B8 and a conveyor belt 10. The conveyor belt 10 is installed on the mounting frame 1 through the transmission wheel A2 and the transmission wheel B8 installed at both ends of the mounting frame 1, and the rough grinding grinding head assembly 6, the fine grinding grinding head assembly 5 and the polishing grinding head assembly 4 are sequentially moved along the moving direction of the conveyor belt 10 Set above the conveyor belt 10. The surface of the conveyor belt A10 is also provided with adhesive glue 7 for bonding and fixing the stone material 3 to be grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com