Ship stern tube bearing dismounting device

A technology for ship stern tube bearings and dismantling devices, which is applied in the direction of transmission devices using synchronous propulsion components, etc., can solve the problems of surface wear of stern shaft holes and failure to ensure the integrity of bearings, and achieve efficient operation, fast and convenient assembly, and structural design ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

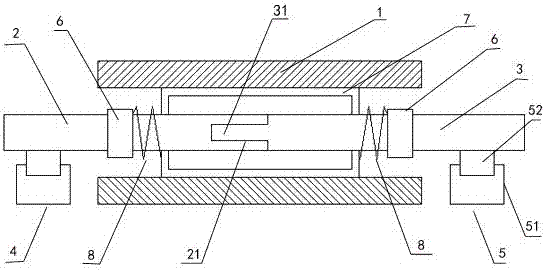

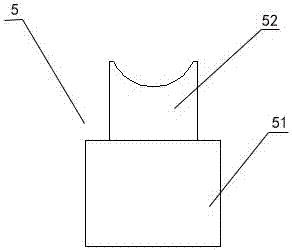

[0016] Such as figure 1 As shown, a ship stern tube bearing removal device includes a stern tube 1, a bearing 7, a first connecting rod 2, a second connecting rod 3, a supporting device 5, and a driving mechanism 4. The bearing 7 is installed in the stern tube 1 . One end of the first connecting rod 2 is provided with a threaded groove 21 . One end of the second connecting rod 3 is provided with a threaded column 31 . The end of the thread groove 21 of the first connecting rod 2 and the threaded post 31 of the second connecting rod 3 are respectively inserted from both ends of the bearing 7 . The thread groove 21 of the first connecting rod 2 and the threaded post 31 of the second connecting rod 3 are internally threaded in the bearing 7 . The support device 5 is installed below the outer end of the second connecting rod 3 . The drive mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com