Construction process of vibrating and sinking of steel cylinder through vibration hammer in linkage mode

A construction technology and steel cylinder technology, applied in infrastructure engineering, construction, etc., can solve problems affecting construction progress, low operating efficiency, and inability to form a self-contained system, so as to reduce uneven force, reduce laying resistance, The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

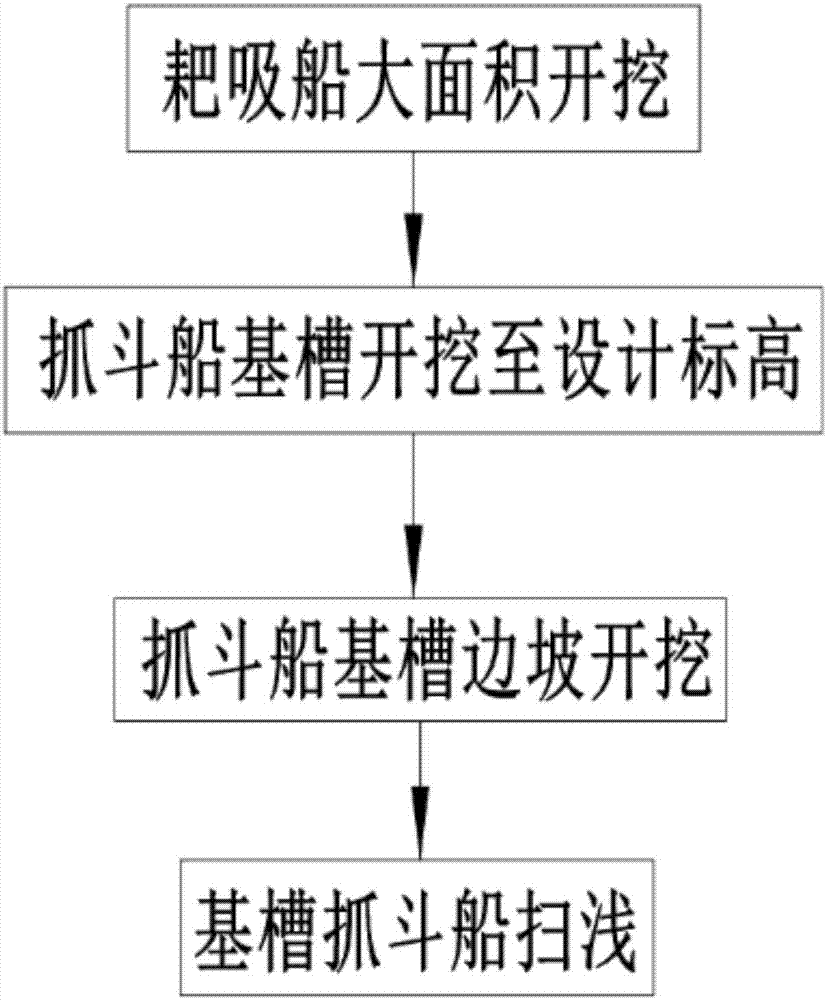

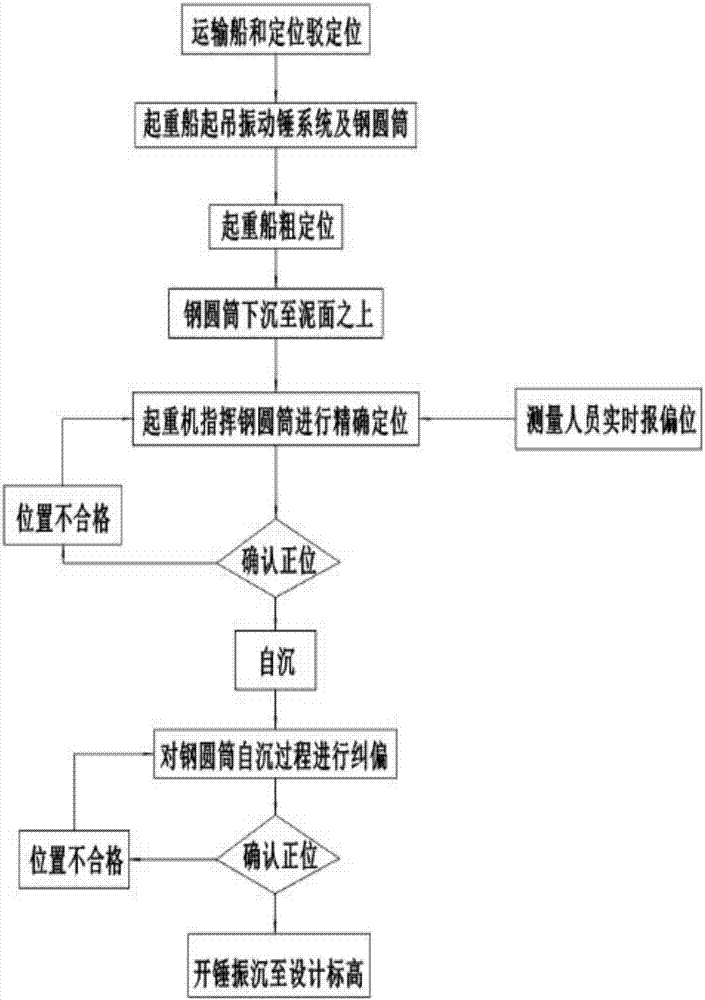

[0031] Such as figure 1 with figure 2 As shown, a construction technique for vibrating hammer-linked vibration-sinking steel cylinder, the specific steps are:

[0032] (1) Pre-construction process

[0033] Excavation of the foundation trench: excavate a large area of the construction area by using a suction boat. After the large-area excavation stage is completed, excavate the foundation trench, slope and shallow sweep of the grab boat;

[0034] Production and transportation of steel cylinders: The production of steel cylinders includes three processes of sheet body, segmentation and final assembly; steel cylinders are transported to the construction site by transport ships after the production is completed;

[0035] (2) Stratum treatment at the construction site

[0036] When the sand layer is 5m, the DSM foundation treatment method is used for treatment. The specific construction method is: use DCM ship to process the sand layer geology at the construction site, and us...

specific Embodiment 2

[0051] A construction technique for vibrating and sinking a steel cylinder linked by a vibrating hammer, the specific steps are as follows:

[0052] (1) Pre-construction process

[0053] Excavation of the foundation trench: excavate a large area of the construction area by using a suction boat. After the large-area excavation stage is completed, excavate the foundation trench, slope and shallow sweep of the grab boat;

[0054] Production and transportation of steel cylinders: The production of steel cylinders includes three processes of sheet body, segmentation and final assembly; steel cylinders are transported to the construction site by transport ships after the production is completed;

[0055] (2) Stratum treatment at the construction site

[0056] When the sand layer is 3m and the N value is 22, the DSM foundation treatment method is used for treatment. The specific construction method is: use the DCM ship to process the sand layer geology at the construction site, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com