Feeding device for shaft riveting

A feeding device and riveting technology, applied in the field of sheet metal parts processing, can solve the problems of high scrap rate, the gear box cannot meet the requirements of use, etc., to improve production efficiency and production automation, ensure riveting accuracy, and ensure processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

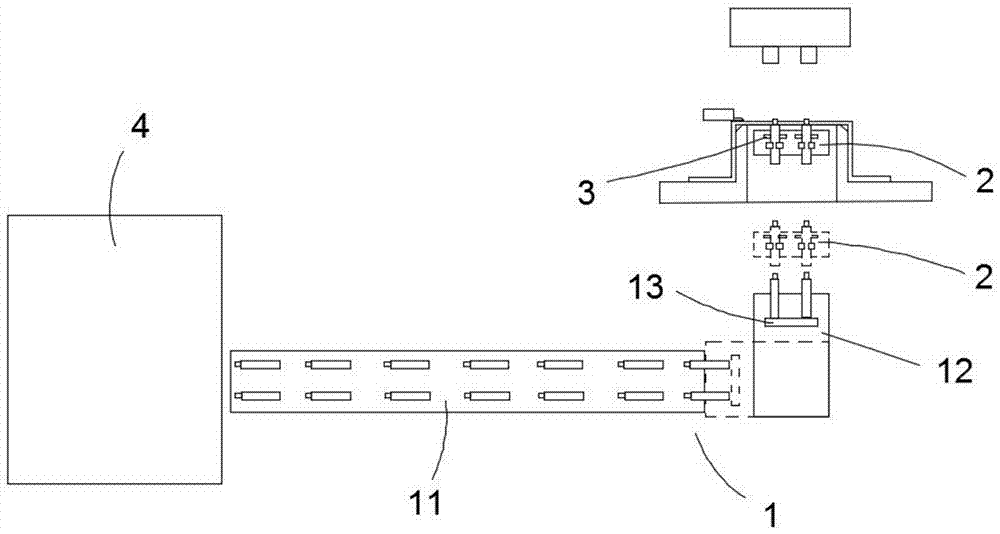

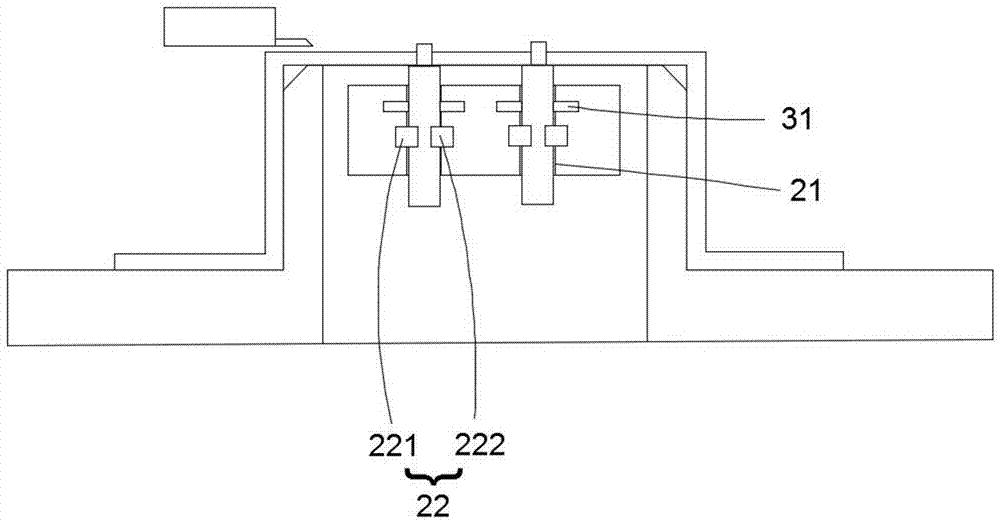

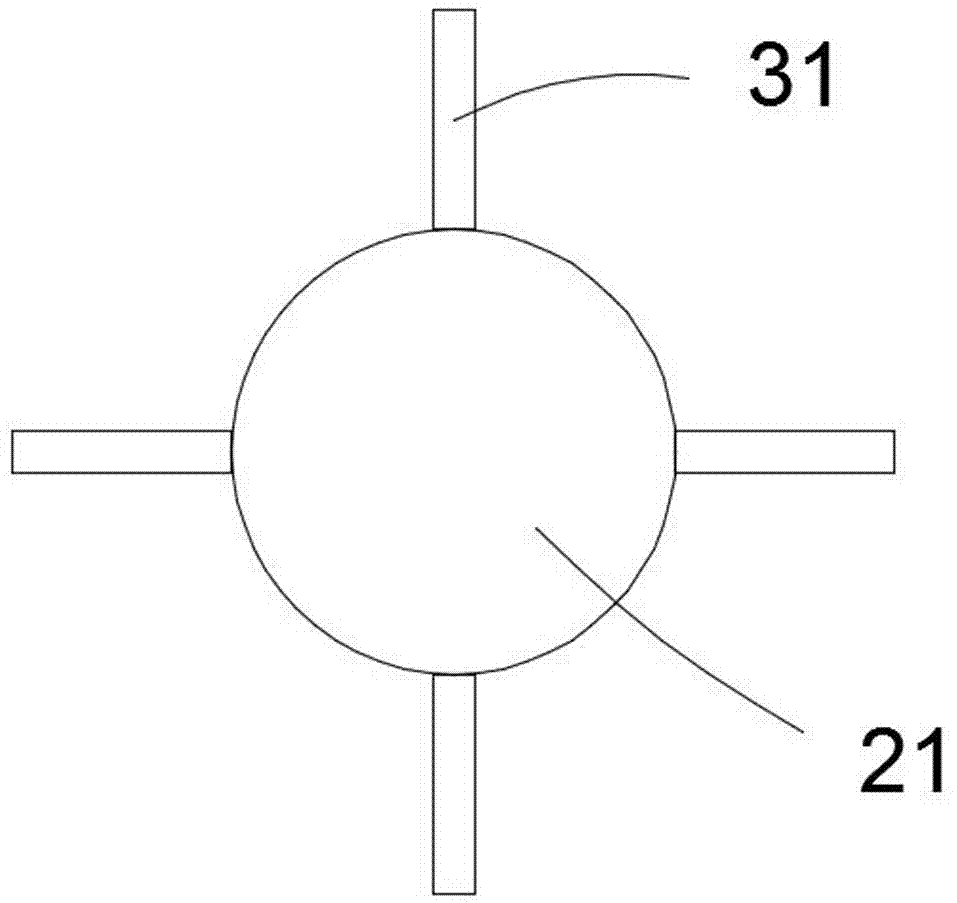

[0023] The invention discloses a feeding device for shaft riveting, such as Figure 1 to Figure 3 As shown, it includes a feeding device 1, a clamping and feeding device 2, a detection and adjustment device 3 and a control module, and the detection and adjustment device 3 includes a verticality detection device, a group of adjustment push rods 31 and an adjustment drive device. The clamping and feeding device 2 includes a set of shaft placement chamber 21, clamping device 22 and clamping drive device; one end of the set of adjusting push rods 31 is arranged in the shaft placement chamber 21, and the other end is connected with the adjustment drive device; The clamping device 22 is connected with a clamping driving device; the clamping and feeding device 2 is connected with a feeding driving device.

[0024] The conveying device 1 described in this embodiment includes a material transfer belt 11 and a material grabbing manipulator 12, the material transfer belt 11 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com