Pneumatic closed run-flat tire with air hole barrier fastener and spacer layer combination and its manufacturing method

A kind of explosion-proof tire and air pressure technology, which is used in tire parts, tires, vehicle parts, etc., to achieve the effect of wide application, safety guarantee, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

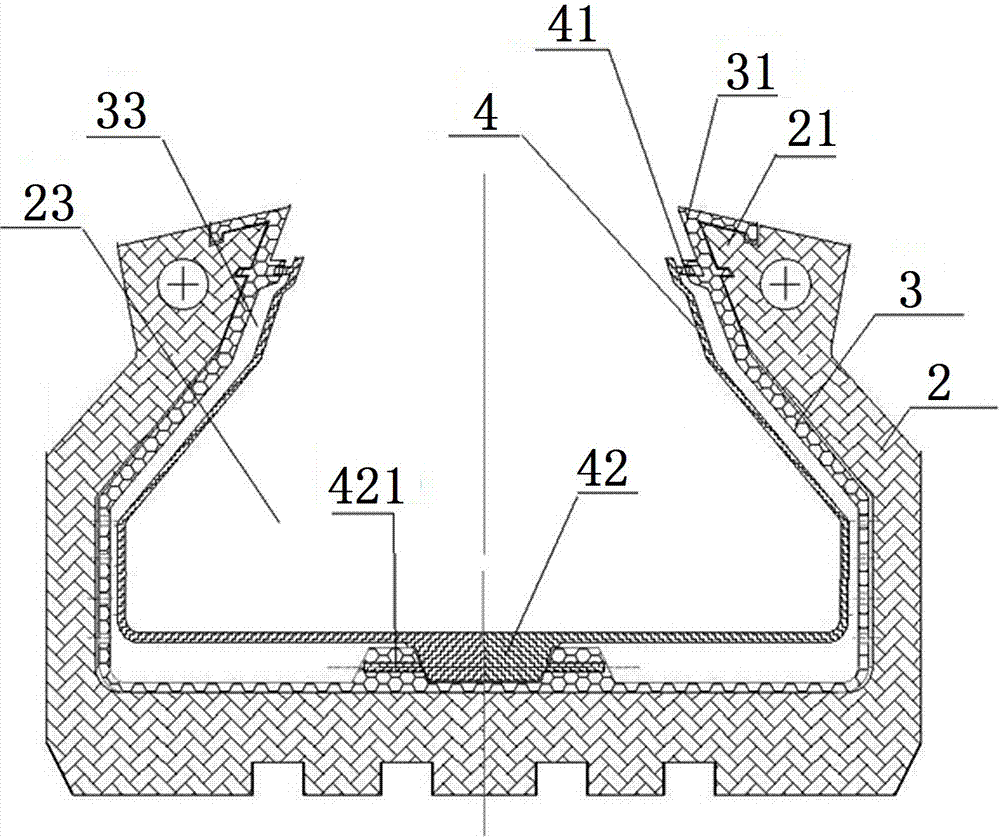

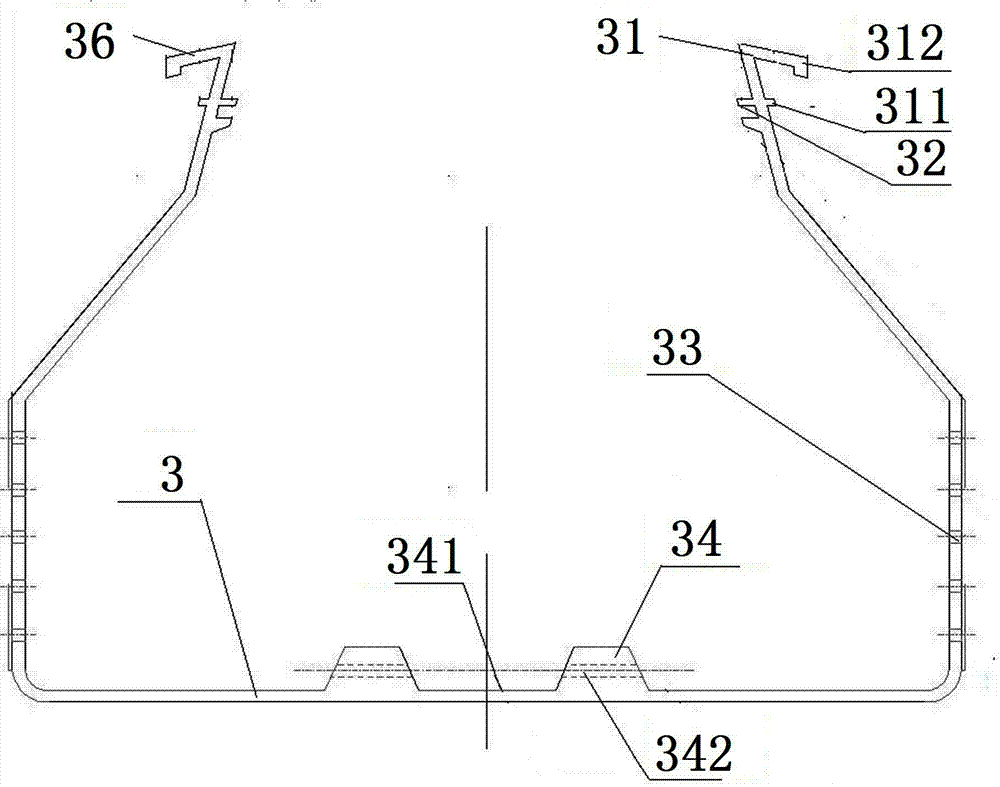

[0048] Such as figure 1 , Figure 1.1 As shown, a pneumatic closed explosion-proof tire with a combination of an air hole barrier fastener and a spacer layer, the tire body 2 is provided with an annular air hole barrier fastener layer 3 adapted to it, and the top of the air hole barrier fastener layer 3 It is interlocked with the bead 10 on the top of the tire body, and the two are fastened and fixed on the wheel hub to form a tire body inner cavity 23. There is a spacer layer kit 4 in the tire body inner cavity 23, and the spacer layer kit 4 is set on the air hole type barrier. There is a certain distance between the fastener layer 3, the spacer layer suite 4 and the air hole barrier fastener layer 3, such as Figure 4 , Figure 4.1 , Figure 4.2 As shown, a third key ring 41 protruding outward is provided along the top of the spacer layer suite 4, and an inward sealing card groove 32 is provided along the top of the air hole type barrier fastener layer 3, and the third ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com