Anti-swinging mechanism for lifting sling of crane

A crane and anti-sway technology, which is applied in the direction of the spring mechanism, the load hanging element, the hoisting device, etc., can solve the problems of low work efficiency and difficulty for the driver to complete the lifting, and achieves low cost, easy manufacture, and simple mechanism structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

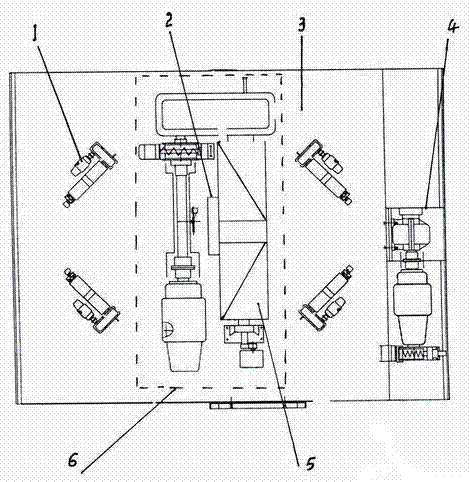

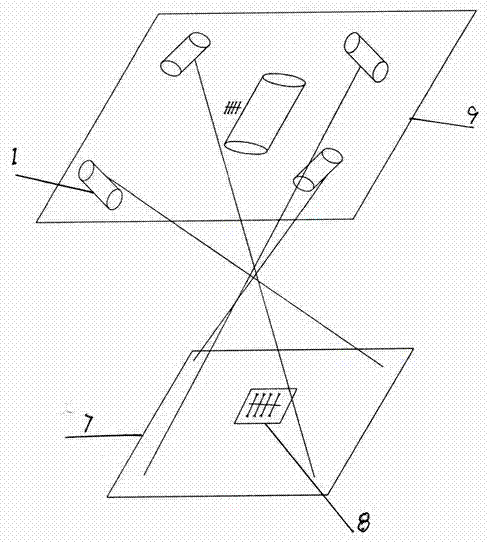

[0009] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 As shown, the mechanism is composed of lifting mechanism 1, fixed pulley block 2, trolley frame 3, trolley running mechanism 4, hoisting mechanism 6, hanging concrete 7, movable pulley block 8 and trolley frame plane 9; Mechanism 6 is composed of a motor connected with a gear coupling and a transmission shaft to drive the gear to run, the brake is connected with a reducer through a brake coupling, and the lifting reel 5 and the reel base on the lifting mechanism 6 are composed. A hoisting mechanism is provided, and the reel is placed in the center of the trolley. The hoisting mechanism is prior art, and the connection of its structure is not described in detail here.

[0010] The central position of described trolley frame 3 is placed with fixed pulley block 2, further said, fixed pulley block is positioned between the transmission shaft on the lifting mechanism and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com