Deputy lock device comprising rotating shaft

A technology of rotating shaft and auxiliary lock, applied in the direction of building lock, building, building structure, etc., can solve the problems of inconvenience and many steps of closing the door, and achieve the effect of low manufacturing cost, compact structure, and quick opening or closing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

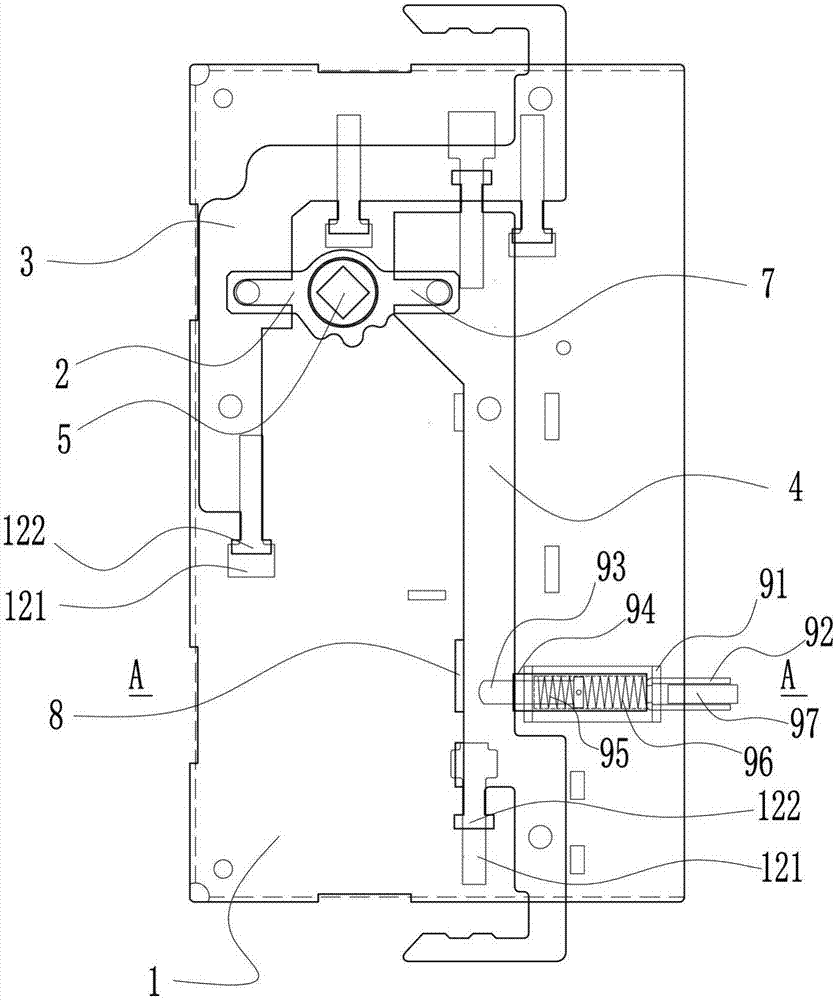

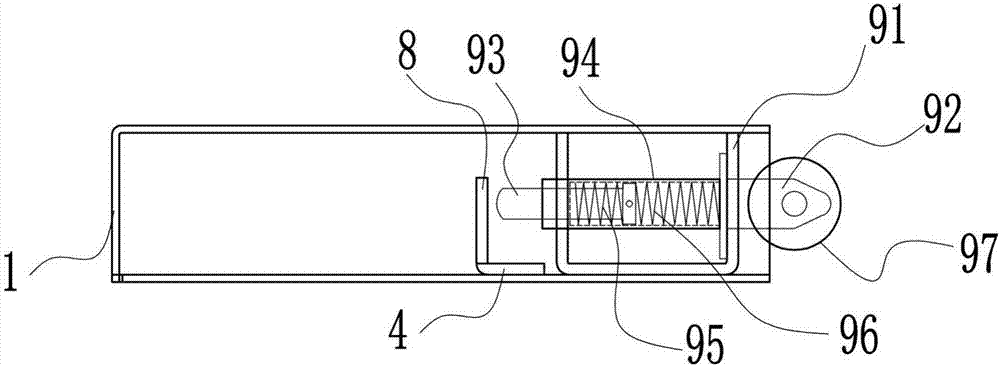

[0040] A rotary shaft auxiliary lock device, such as Figure 1 to Figure 4 As shown, it includes a lock case 1, a telescopic assembly that moves relative to the lock case 1, and a safety assembly installed on the lock case 1;

[0041] The telescopic assembly includes a swing rod 2, a transmission piece I3, and a transmission piece II4; the swing rod 2 is provided with a shaft hole 5, and two ends are provided with bumps 6; one end of the swing rod 2 is connected to the transmission piece I3 through the bump 6, and the other end is connected to the transmission piece I3. It is connected with the transmission piece II4; the transmission piece I3 and the transmission piece II4 are provided with groove I7, and the convex point 6 and the groove I7 are slidingly fitted; the transmission piece II4 is provided with a safety catch I8, such as Figure 15 shown;

[0042] The lock housing 1 is provided with a card slot 121, and both the transmission piece I3 and the transmission piece II...

Embodiment 2

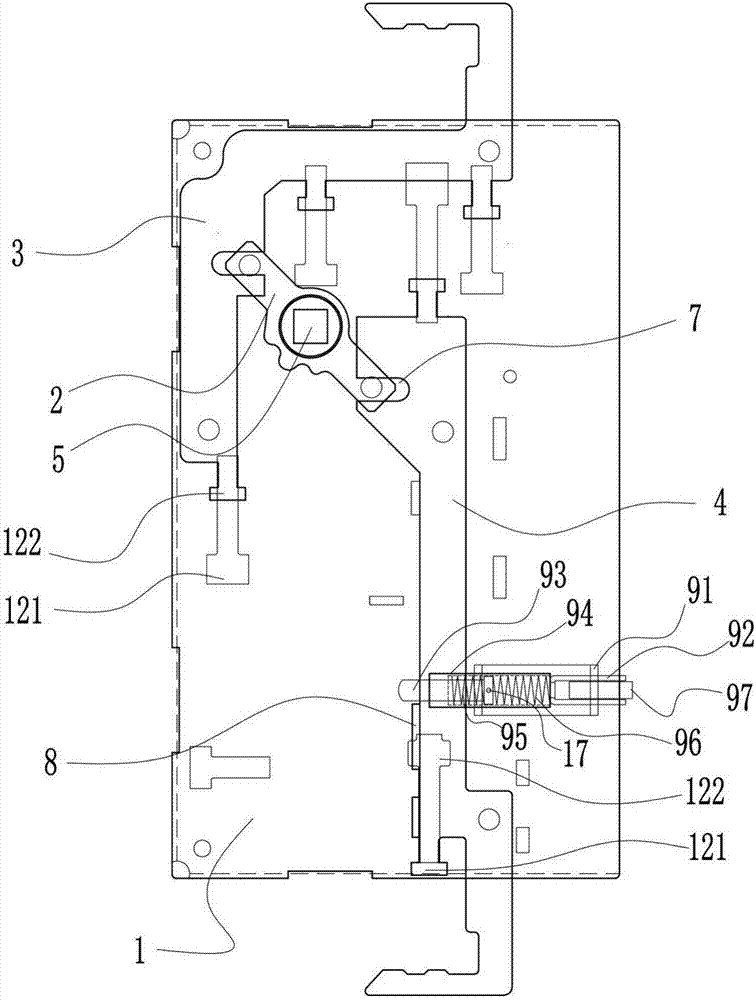

[0047] A rotary shaft auxiliary lock device, such as Figure 6 As shown, it includes a lock case 1, a telescopic assembly that moves relative to the lock case 1, and a safety assembly installed on the lock case 1;

[0048] The telescopic assembly includes a swing rod 2, a transmission piece I3, and a transmission piece II4; the swing rod 2 is provided with a shaft hole 5, and two ends are provided with bumps 6; one end of the swing rod 2 is connected to the transmission piece I3 through the bump 6, and the other end is connected to the transmission piece I3. It is connected with the transmission piece Ⅱ4; the transmission piece Ⅰ3 and the transmission piece Ⅱ4 are provided with the groove Ⅰ7, and the convex point 6 and the groove Ⅰ7 are slidably fitted; the transmission piece Ⅱ4 is provided with the safety catch Ⅰ8;

[0049] The drive piece I3 and the drive piece II4 are both provided with groove II131; the lock housing 1 is provided with a column point 132, and the column poi...

Embodiment 3

[0053] A rotary shaft auxiliary lock device, such as Figure 7 As shown, it includes a lock case 1, a telescopic assembly that moves relative to the lock case 1, and a safety assembly installed on the lock case 1;

[0054] The telescopic assembly includes a swing rod 2, a transmission piece I3, and a transmission piece II4; the swing rod 2 is provided with a shaft hole 5, and two ends are provided with bumps 6; one end of the swing rod 2 is connected to the transmission piece I3 through the bump 6, and the other end is connected to the transmission piece I3. It is connected with the transmission piece Ⅱ4; the transmission piece Ⅰ3 and the transmission piece Ⅱ4 are provided with the groove Ⅰ7, and the convex point 6 and the groove Ⅰ7 are slidably fitted; the transmission piece Ⅱ4 is provided with the safety catch Ⅰ8;

[0055] The lock housing 1 is provided with a chute 14 , and the transmission piece I3 and the transmission piece II4 pass through the chute 14 and move in the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com